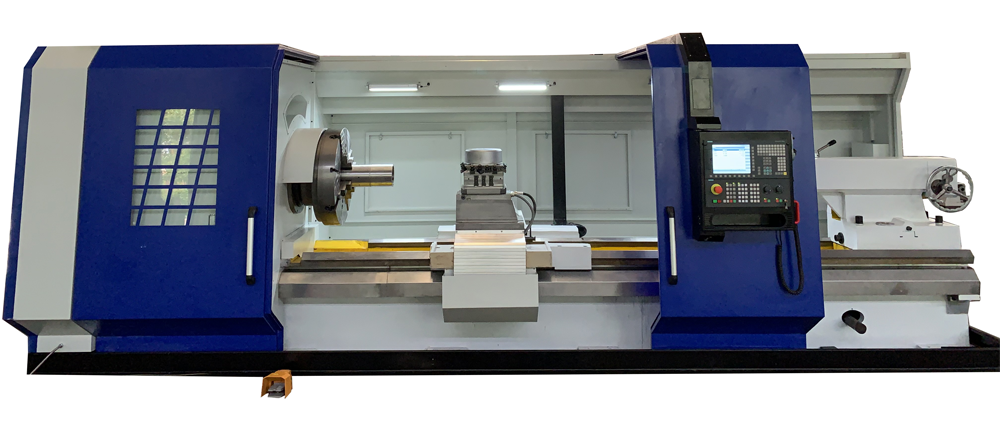

TheCNC chitoliro ulusi latheimatha kukonza ulusi wosiyanasiyana ndi malo ozungulira, ndipo ndi yoyenera kutembenuza mitundu yonseulusi wa pipe. Kuti makina ofunikira pamwamba pa workpiece, chida ndi workpiece ayenera kukhala olondola wachibale kuyenda, amene anazindikira ndi dongosolo mapulogalamu. Kuyenda kwa spindle apayipi yopangira lathendiye kayendetsedwe kake, ndipo kulondola kwa kufalitsa kwake kumakhudza mwachindunji ubwino wa makina opangidwa ndi makina.

Ngakhale bombakuchotsa lathendi lathe wapadera kwa mafakitale oilfield, angagwiritsidwenso ntchito ngati lathe chikhalidwe. Mphamvu yodula ikugwirizana ndi zida zosankhidwa, zida zogwirira ntchito komanso kuchuluka kwa kudula.

Nthawi zambiri timakumana ndi enaCNC makina chidaogulitsa omwe atipempha kuti tisinthe mapangidwe a spindle aulusi wa payipi latheszochokera zinachitikira lathes chikhalidwe kupanga izo kotheratu dongosolo spindle wa ambiri CNC lathes, kuti kuonetsetsa chilengedwe cha zida. Koma kusintha koteroko sikutheka. M'munsimu muli tsatanetsatane wa spindle yadziko la mafuta.

The spindle part of thelathe ulusi wa pipendi chimodzi mwa zigawo zofunika za chida makina, kuphatikizapo thandizo la spindle ndi kufala mbali anaika pa spindle. Chifukwa cha liwiro lalitali, mphamvu yayikulu, komanso kusintha kwamanja kwaCNC makinazida pakukonza, kulondola kozungulira kwabwino, kukhazikika kwamapangidwe, kukana kugwedezeka, kukhazikika kwamafuta, kukana kuvala ndi kusungidwa kolondola kwa zigawo zimafunikira. Kuti muzindikire kutsitsa ndi kutsitsa ndi kukanikiza pa spindle, payenera kukhala chida cholumikizira chodziwikiratu cha chidacho, chida choyimitsira spindle ndi chida chodulira bwino.

Thandizo lakutsogolo laulusi wa bombalathe spindle imatenga mizere iwiri ya cylindrical roller yokhala ndi mkati mwa tapered kuti ikhale ndi mphamvu yozungulira, yomwe imapangitsa kulimba kwa nsonga ya spindle ndi kusinthasintha kozungulira kwa spindle. Miyendo iwiri ya mpira wa thrust imagwiritsidwa ntchito kunyamula mphamvu ya axial ndikuchepetsa kuyenda kwa axial kwa spindle. Momentum imapangitsa kuti axial rigidity ya spindle ikhale yabwino. Thandizo lakumbuyo limakhala ndi mizere iwiri ya cylindrical roller yokhala ndi mkati mwa tapered bore, yomwe imagwira ntchito yothandizira ma radial.

TheCNC chitoliro ulusi latheimapangidwa ndikupangidwira kutembenuza kwaphala la mafutaulusi, ndipo ndi oyenera kutembenuza mitundu yonse ya ulusi wa chitoliro. Makhalidwe otuluka a spindle amakhudza mwachindunji kukhazikika komanso kulondola kwakukulu kwa chida cha makina. Chifukwa ndikofunikira kwambiri kusanthula ndi kuphunzira mawonekedwe amphamvu amtundu wa spindle. Kupyolera mu kusanthula kwa modal kwa spindle, chikoka cha kulingalira kwa kapangidwe kake pa kulondola kwa chida cha makina chimaphunziridwa, ndipo zigawo zofunikira zimakongoletsedwa kuti zigwirizane ndi zofunikira za makina opangira khalidwe ndi kulondola.

Nthawi yotumiza: Nov-20-2021