Ndikoyamba kuti makasitomala akumadera ena apadera akumane nawoZithunzi za CNC, ndipo ntchito ya CNC lathes akadali sangathe kudziwa luso la makina ogwiritsira ntchito kokha kuchokera ku chitsogozo cha bukhu la opareshoni. Kuphatikiza zochitika zogwirira ntchito zomwe zasonkhanitsidwa ndi odziwa zambiriChina CNC latheogwira ntchito pa ntchito yawo ya tsiku ndi tsiku, ndikufotokozerani luso la kukhazikitsa zida ndi masitepe okonza mbali zina.

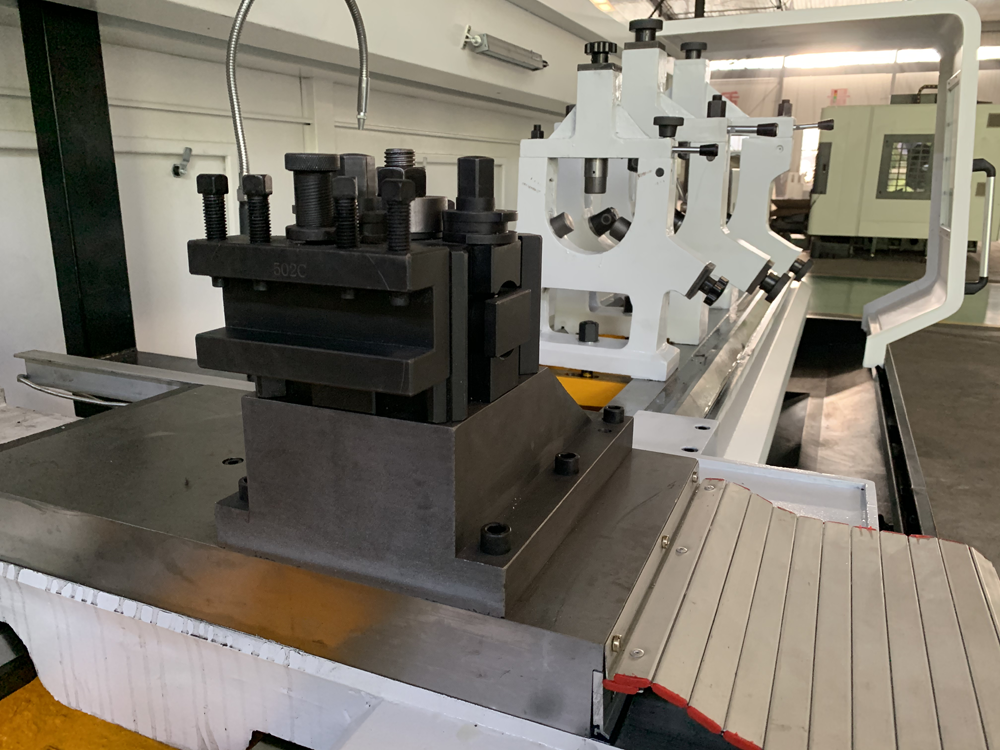

Njira ndi luso la kukhazikitsa zida mumakampani opanga makina zitha kugawidwa m'magulu awiri: kukhazikitsa zida zolunjika ndi kukhazikitsa zida. Pamaso pa CNC lathe kubwerera poyambira, aliyensekutembenukansol yomwe ikufunika kugwiritsidwa ntchito imayikidwa ndi malo apakati a mphero yoyenera ya gawolo ngati 0 point, ndiyeno malo apakati a nkhope yotembenukira kumanja ya gawolo amasankhidwa ngati 0 point ndipoCNC chidamfundo yakhazikitsidwa. Chida chotembenuza chikakhudza kiyibodi yakumanja ya mphero, kuyika Z0 ndikudina kuti muwone, chiwongola dzanja cha chida chosinthira chimangosunga zomwe zapezeka, zomwe zikutanthauza kuti chida cha Z-axis chamalizidwa, ndikuyika chida cha X. ndi chida chodulira choyeserera, ndipo chodulira mphero chimagwiritsidwa ntchito Chizungulire chakunja cha mbali zamagalimoto ndi chocheperako, ndipo data yozungulira yagalimoto yodziwika (monga x ndi 20 mm) kiyibodi yolowetsa x20, dinani kuti muwone, chida. chipukuta misozi chidzangopulumutsa deta yomwe yapezeka, panthawiyi x-axis imatsirizidwanso.

Chida ichi chokhazikitsa njira, ngakhale zitakhalaChithunzi cha CNCyatha mphamvu, mtengo woyika zida sudzasinthidwa mphamvu ikayambiranso. Itha kugwiritsidwa ntchito pakupanga kwanthawi yayitali ndikukonza magawo omwewo. Panthawiyi, makinawo safunikira kuyesedwanso pamene makina atsekedwa.

(1) Menyani kaye kenako n’kufika kumapeto (uku n’kupewa kuchuna pokhomerera).

(2) Kutembenuka koyipa koyamba, kenako kutembenuka bwino (uku ndikuwonetsetsa kulondola kwa magawo).

(3) Choyamba konzekerani omwe ali ndi mipata ikuluikulu ndiyeno pangani omwe ali ndi mipata yaying'ono (izi ndikuwonetsetsa kuti kunja kwa kusiyana kochepa sikukuphwanyidwa ndikupewa kupotoza mbali).

(4) Sankhani liwiro lolondola, kuchuluka kwa kudula ndi kuya kwa kudula molingana ndi kuuma kwake. Zida za carbon steel plate zimasankhidwa kuti zizisinthasintha mofulumira, kudula kwambiri, ndi kudula kwakukulu. Monga: 1Gr11, gwiritsani ntchito S1 600, F0.2, ndi kudula kuya 2 mm. Alloy amagwiritsa ntchito liwiro lotsika, kuchuluka kwa chakudya chochepa komanso kuzama kochepa. Monga: GH4033, sankhani S800, F0.08, ndi kudula kuya 0.5mm. Chitsulo cha Titanium alloy chimasankha chiŵerengero chotsika kwambiri, kudula kwakukulu, ndi kuya kwazing'ono. Monga: Ti6, gwiritsani ntchito S400, F0.2, ndi kudula kuya 0.3mm. Tengani kapangidwe ka gawo lina monga chitsanzo: zinthuzo ndi K414, zomwe ndi zinthu zolimba kwambiri. Pambuyo poyesedwa mobwerezabwereza, kusankha komaliza ndi S360, F0.1, ndi kuya kwa odulidwa 0.2, magawo asanayambe kupangidwa. (Izi ndi zongonena zokha, chonde pangani zosintha zenizeni potengera magawo a makina apamalo, zida, ndi zina zambiri!)

Nthawi yotumiza: Nov-29-2021