makina ochiritsira lathendi mtundu wa mwambo lathe makina popanda ulamuliro koma Buku. Ili ndi mitundu yambiri yodulira ndipo imatha kukonza mabowo amkati, mabwalo akunja, nkhope zomapeto, malo okhala ndi tapered, chamfering, grooving, ulusi ndi ma arc osiyanasiyana. Ma lathe ochiritsira ndi mtundu womwe amagwiritsidwa ntchito kwambiri pamakina a lathe, omwe amawerengera pafupifupi 65% ya kuchuluka kwa makina onse. Amatchedwa lathes yopingasa chifukwa zopota zake zimayikidwa mopingasa.

Ntchito:

1. Kutembenuka kwamphamvu yakunja, kutembenuka kwa kondomu, kutembenuka kokhota, kutembenuka kwa dzenje lamkati, kutembenukira kumapeto, kupotoza ndi makina ena;

2. Metric thread, inchi ulusi, modular ulusi, phula kudula ulusi;

3. Kuwombera ndi kutembenuka kwakutali;

4. Kubowola, kunyong’onyeka, kuboola ndi kukumba;

5. Kutembenuka kwa dzanja lamanzere ndi kumanja;

6. Ngakhale kugaya ndi mphero ndi mphero ndi mphero attachment.

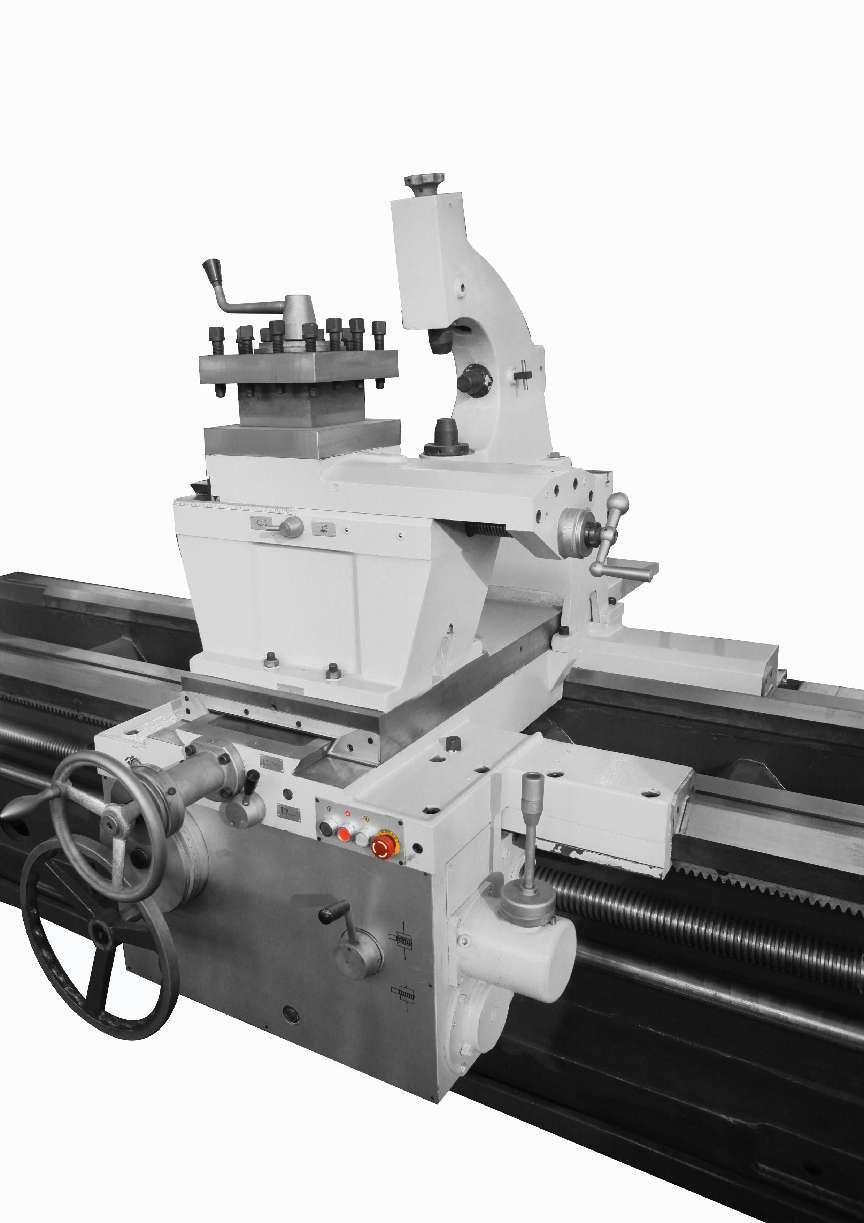

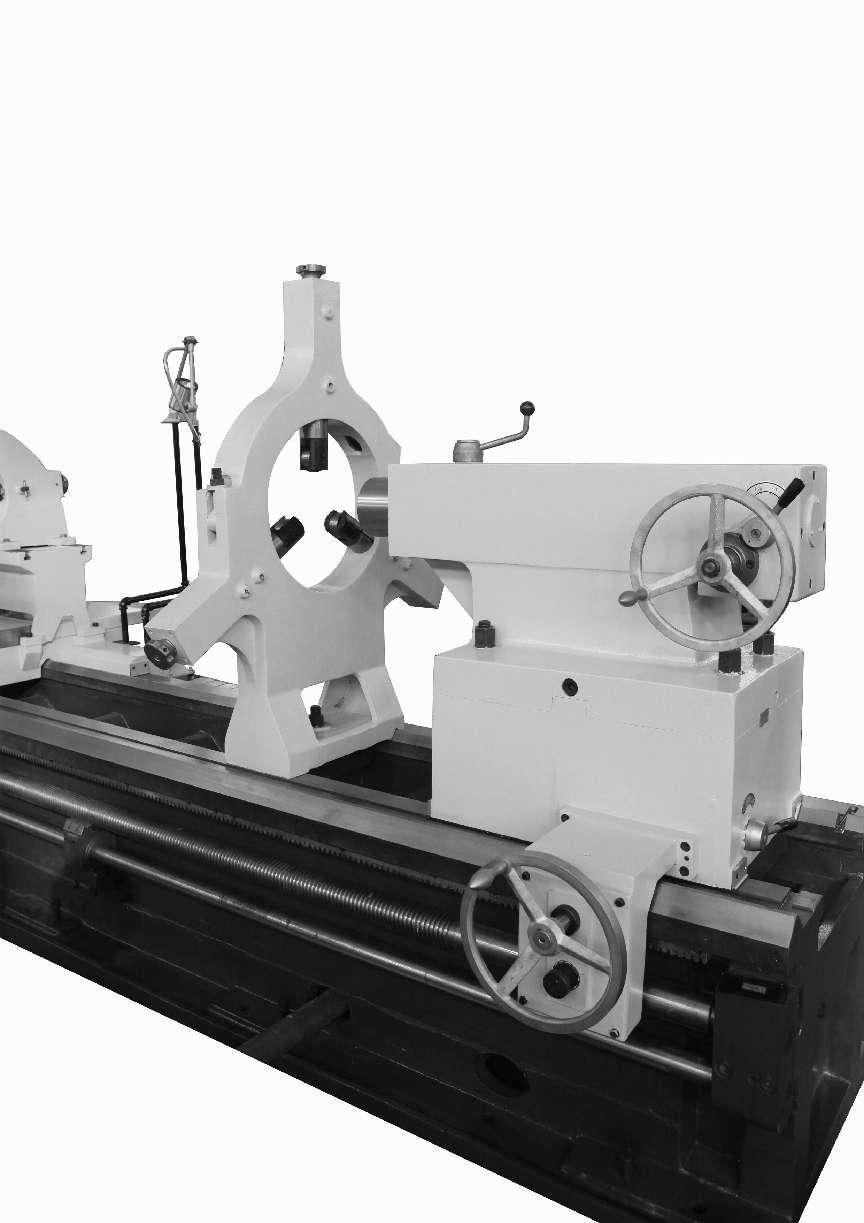

Zigawo zazikulu zamakina wamba: bedi,mutu,bokosi la chakudya, positi zida, ngolo, tailstock, ndi galimoto.

Bedi: Mbali zazikulu zamakina osindikiziraamaikidwa pa bedi, kuti akhalebe olondola wachibale udindo pa ntchito.The ngolo ndi tailstock Wopanda pa finely machined bedi pamwamba.

Headstock:mutu wamutu umayikidwa mwamphamvu ku bedi ndipo umagwira njira zonse, kuphatikizapo mitundu yosiyanasiyana ndi kuphatikiza kwa ma pulleys kapena ma gears. amatha kupeza maulendo osiyanasiyana ofunikira a kutsogolo ndi kumbuyo, ndipo panthawi imodzimodziyo, mutuwo umagawaniza mbali ya mphamvu kuti ipereke kayendedwe ka bokosi la chakudya. Headstock Medium spindle ndi gawo lofunikira la lathe. kuthamanga pa chonyamulira mwachindunji zimakhudza khalidwe processing wa workpiece. Kasinthasintha kasinthasintha ka spindle kachepetsedwa, mtengo wogwiritsa ntchito wamakina chidaadzachepetsedwa.

Bokosi la chakudya: Bokosi la chakudya lili ndi njira yosinthira liwiro kuti muyendetse. Sinthani makina osinthira liwiro kuti mupeze kuchuluka kwa chakudya kapena phula lofunikira, ndipo perekani zoyenda kwa chotengera chida kudzera pa screw yosalala kapena zomangira zowongolera podula. Zowongolera zotsogola zimagwiritsidwa ntchito mwapadera kutembenuza ulusi wosiyanasiyana. Potembenuza malo ena a workpiece, screw yosalala yokha imagwiritsidwa ntchito m'malo mwa screw screw.

Chogwirizira: Chosungira chida chimapangidwa ndi zigawo zingapo za zida. Ntchito yake ndikuchepetsa chida ndikupangitsa chidacho kuyenda motalika, mozungulira kapena mozungulira.

Tailstock: Monga likulu lakumbuyo lothandizira malo, lingathenso kukhazikitsidwa ndi zida zopangira dzenje monga zobowolera ndi reamers pokonza dzenje.

magawo

Nsagwada zitatu chuck (za cylindrical workpieces)

nsagwada zinayi chuck (kwa ntchito zosakhazikika)

khalidwe

Zida zamakina ochiritsirakukhala ndi dongosolo losavuta, ntchito yosavuta, m'mimba mwake yaikulu ya spindle, phazi laling'ono, kusinthasintha kwakukulu kwa processing, kukonza kosavuta, koyenera kukonzedwa kwa batch yaing'ono ndi ntchito yokwera mtengo.

Bedi limatenga bedi lofunika kwambiri lolimba kwambiri.Makinawa ali ndi pampu yosiyana ya mafuta. Slide, chosungira zida, ndi chishalo zimatha kuyenda mwachangu. Chida ichi chimatha kutengera dongosolo la GSK kapena SIEMENS yosankha, FANUC yowongolera manambala ndi njira zina zowongolera manambala malinga ndi zomwe wogwiritsa ntchito akufuna, zomwe zimatha kudula mwachangu, mwamphamvu komanso mokhazikika, kulondola kwaukadaulo wapamwamba komanso mapulogalamu osavuta.

Theofukula ndi yopingasafeed imatenga AC servo motor, ndipo ndemanga ya pulse encoder imagwiritsidwa ntchito ngati mayankho. The ofukula ndi yopingasa zoyenda kalozera njanji ndi pansi akupanga kuumitsa ndi chabwino akupera mankhwala. Njanji yowongolera bedi imayikidwa ndi tepi yofewa ya PTFE, ndipo chigawo cha mikangano ndi chaching'ono.

Galimoto yayikulu imatenga njira yophatikizira kuthamanga kwa maginito ndi kuwongolera ma voliyumu, kuti ipangitse kuthamanga kwa spindle mopanda mayendedwe.

Njira zogwirira ntchito

1. Kuyang'ana musanayambe

1.1 Onjezani mafuta oyenerera malinga ndi tchati chopaka mafuta pamakina.

1.2 Yang'anani zida zonse zamagetsi, chogwirira, magawo otumizira, zida zoteteza ndi malire ndizokwanira, zodalirika komanso zosinthika.

1.3 Giya iliyonse iyenera kukhala pamalo a zero, ndipo kugwedezeka kwa lamba kuyenera kukwaniritsa zofunikira.

1.4 Sizololedwa kusunga zinthu zachitsulo mwachindunji pabedi, kuti zisawononge bedi.

1.5 Chogwirira ntchito chomwe chiyenera kukonzedwa sichikhala ndi matope ndi mchenga, kuteteza matope ndi mchenga kuti zisagwe m'makina ndikuwononga njanji yowongolera.

1.6 Chidutswacho chisanayambe kutsekedwa, ntchito yoyesa galimoto yopanda kanthu iyenera kuchitidwa, ndipo chogwiritsira ntchito chikhoza kuikidwa pokhapokha mutatsimikizira kuti zonse ndi zachilendo.

2. Ndondomeko ya ntchito

2.1 Chidutswacho chikakhazikitsidwa, yambani pompa yamafuta opaka mafuta kaye kuti mphamvu yamafuta ikwaniritse zofunikira zamakina musanayambe.

2.2 Posintha choyikapo chosinthira zida, posintha gudumu lopachikidwa, magetsi ayenera kudulidwa. Pambuyo pakusintha, mabawuti onse ayenera kulumikizidwa, wrench iyenera kuchotsedwa munthawi yake, ndipo chogwirira ntchito chiyenera kulumikizidwa kuti chiyesedwe.

2.3 Mukatsitsa ndikutsitsa chogwirira ntchito, wrench ya chuck ndi magawo oyandama a workpiece ayenera kuchotsedwa nthawi yomweyo.

2.4 Chingwe cha tailstock, crank handle, etc. cha chida cha makina chidzasinthidwa kuti chikhale choyenera malinga ndi zofunikira zogwirira ntchito, ndipo chidzamangidwa kapena kutsekedwa.

2.5 Zida zogwirira ntchito, zida ndi zida ziyenera kuyikidwa bwino. Chida choyandama champhamvu chimayenera kukulitsa gawo lotsogolera muzogwirira ntchito musanayambe chida cha makina.

2.6 Mukamagwiritsa ntchito mpumulo wapakati kapena mpumulo wa chida, malowo ayenera kusinthidwa bwino, ndipo payenera kukhala mafuta odzola bwino ndikuthandizira malo okhudzana.

2.7 Pokonza zinthu zazitali, mbali yotuluka kumbuyo kwa shaft yayikulu siyenera kukhala yayitali kwambiri.

2.8 Podyetsa mpeni, mpeni uyenera kuyandikira ntchitoyo pang'onopang'ono kuti usawombane; liwiro la chonyamulira liyenera kukhala lofanana. Posintha chidacho, chida ndi chogwirira ntchito ziyenera kusungidwa patali yoyenera.

2.9 Chida chodulira chiyenera kulumikizidwa, ndipo kutalika kwa chida chotembenuza nthawi zambiri sikuposa 2.5 makulidwe a chidacho.

2.1.0 Popanga zigawo za eccentric, payenera kukhala zotsutsana zoyenera kuti zigwirizane ndi mphamvu yokoka ya chuck, ndipo liwiro la galimoto liyenera kukhala loyenera.

2.1.1. Payenera kukhala zodzitetezera kwa workpiece amene chuck kupitirira fuselage.

2.1.2 Kusintha kwa makonzedwe a chida kuyenera kukhala pang'onopang'ono. Pamene nsonga ya chida ndi 40-60 mm kutali ndi gawo lokonzekera la workpiece, chakudya chamanja kapena chogwirira ntchito chiyenera kugwiritsidwa ntchito m'malo mwake, ndipo chakudya chofulumira sichiloledwa kugwiritsira ntchito chidacho.

2.1.3 Popukuta chogwirira ntchito ndi fayilo, chogwiritsira ntchito chiyenera kubwezeredwa pamalo otetezeka, ndipo wogwiritsa ntchitoyo ayang'ane ndi chuck, ndi dzanja lamanja kutsogolo ndi kumanzere kumbuyo. Pali njira yayikulu pamwamba, ndipo ndizoletsedwa kugwiritsa ntchito fayilo pokonza chogwirira ntchito ndi dzenje lalikulu.

2.1.4 Popukuta bwalo lakunja la chogwirira ntchito ndi nsalu ya emery, wogwiritsa ntchitoyo ayenera kugwira nsonga ziwiri za nsalu ya emery ndi manja onse kuti apukutire molingana ndi kaimidwe komwe tafotokozera m'nkhani yapitayi. Ndizoletsedwa kugwiritsa ntchito zala zanu kuti mugwire nsalu yopukutira kuti mupukutire dzenje lamkati.

2.1.5 Panthawi yodyetsa mpeni, chogwiritsira ntchito mpeni chaching'ono chiyenera kusinthidwa kuti chizitsuka ndi maziko kuti maziko asakhudze chuck.

2.1.6 Pamene kudula workpieces zazikulu ndi zolemetsa kapena zipangizo, zokwanira Machining allowance ayenera kusungidwa.

3. Kuyimitsa magalimoto

3.1 Dulani mphamvu ndikuchotsa chogwirira ntchito.

3.2 Zogwirizira za gawo lililonse zimagwetsedwa mpaka zero, ndipo zida zimawerengedwa ndikutsukidwa.

3.3 Yang'anani momwe chida chilichonse chotetezera chilili.

4. Kusamala panthawi ya ntchito

4.1 Ndizoletsedwa kuti osagwira ntchito azigwiritsa ntchito makinawo.

4.2 Ndizoletsedwa kukhudza chida, gawo lozungulira la chida cha makina kapena chogwirira ntchito chozungulira.

4.3 Sizololedwa kugwiritsa ntchito kuyimitsa mwadzidzidzi. Pakachitika mwadzidzidzi, mutatha kugwiritsa ntchito batani ili kuti muyime, iyenera kufufuzidwanso molingana ndi malamulo musanayambe chida cha makina.

4.4 Sizololedwa kuponda panjanji ya kalozera, ndodo, ndodo yopukutidwa, ndi zina zotero. Kupatula malamulo, sikuloledwa kugwiritsa ntchito chogwirira ndi mapazi m'malo mwa manja.

4.5 Pazigawo zokhala ndi matuza, mabowo opukutira kapena makiyi pakhoma lamkati, scrapers ya triangular saloledwa kudula mabowo amkati.

4.6 Mpweya woponderezedwa kapena kuthamanga kwamadzi kwa pneumatic kumbuyo kwa hydraulic chuck kuyenera kufika pamtengo womwe watchulidwa musanagwiritse ntchito.

4.7 Potembenuza zogwirira ntchito zowonda, pamene kutalika kwa mbali ziwiri za mutu wa bedi kumapitirira maulendo 4, likulu liyenera kugwiritsidwa ntchito motsatira ndondomeko ya ndondomeko. Thandizo la kupuma kwapakati kapena chidendene. Alonda ndi zizindikiro zochenjeza ziyenera kuwonjezeredwa pamene zituluka kumbuyo kwa mutu wa bedi.

4.8 Podula zitsulo zophwanyika kapena kudula kosavuta (kuphatikizapo kugaya), zotetezera ziyenera kuwonjezeredwa, ndipo ogwira ntchito ayenera kuvala magalasi otetezera.

zina

Ndi kutchuka kwaCNC makina,zida zowonjezera zowonjezera zikutuluka pamsika.Traditional lathesali ndi zabwino zawo zomwe sizingalowe m'malo mwake ndipo akadali makina ofunikira pamakampani ambiri okonza.

1. Zida zamakina ochiritsirandi zotsika mtengo

Mtengo wogula waZithunzi za CNCndi okwera mtengo kangapo kuposa wamba lathe ndi mphamvu yomweyo, ndipo kukonzanso pambuyo pake, kukonza, kuthandizira zogwiritsira ntchito ndi ndalama zina ndizokwera kwambiri kuposa izo.

2.Zowonjezera zoyenera pamakina ang'onoang'ono

Pamene magulu ang'onoang'ono okha workpieces ayenera Machining,antchito aluso kwambiri amatha kuyika gawolo ndi zida zamakina wamba okhala ndi zojambula za magawo.

3.Malipiro apamwamba a olemba mapulogalamu a CNC ndi matalente ochepa

Olemba mapulogalamu a CNC nthawi zambiri amafuna malipiro apamwamba, ndipo pali mitundu yambiri ya machitidwe a CNC. Mwachiwonekere n'kovuta kupeza wogwiritsa ntchito yemwe ali walusoCNC makina zidakuposa wogwiritsa ntchito makina wamba.

4.Za ndalama zogulira bizinesi

Poganizira kuchuluka kwa ndalama zamabizinesi komanso kugwiritsa ntchito bwino zida, mabizinesi ambiri amapitilira kupangamakina ochiritsirazida.

Zonsezi, ngakhale kuti kupanga CNC kwakhala njira yaikulu pakukula kwa makampani opanga zinthu, zida zamakina ochiritsira zimakhalabe ndi ubwino wawo wapadera pankhani ya kutchuka kwa zida zanzeru. Ndi kupititsa patsogolo kosalekeza kwa nzeru zaCNC makina zidam'tsogolo, zida zamakina zachikhalidwe zitha kusinthidwa pamlingo waukulu, koma sizingatheke kuzichotsa kwathunthu.

| CHITSANZO | CW61(2)63E | CW61(2)80E | CW61(2)100E | CW61(2)120E | CWA61100 |

| ZOTHANDIZA | |||||

| Max akugwedezeka pabedi | 630 mm | 800 mm | 1000 mm | 1200 mm | 1000 mm |

| Max.kuzungulira pamtanda | 350 mm | 485 mm | 685 mm | 800 mm | 620 mm |

| Max.kutembenuza kutalika | 750,1250,1750,2750,3750,4750,5750,7750,9750,11750mm | 1.5m 2m 3m 4m 5m 6m 8m 10m 12m | |||

| Max.kugwedezeka pa kusiyana | 830 mm | 1000 mm | 1200 mm | 1400 mm | 780 mm |

| Kutalika kovomerezeka kwa kusiyana | 230m ku | 8T | |||

| Kuchuluka kwa bedi | 550 mm | ||||

| MITU YA NKHANI | Φ130 mm | ||||

| Bowo la spindle | 105mm KAPENA 130mm (POSAFUNA CW6180E+) | Metric140 # | |||

| Mphuno ya spindle | D-11 kapena C-11 | 3.15-315r/mphindi kapena 2.5-250r/mphindi | |||

| Spindle taper | Φ120mm taper1:20(Φ140, OPANDA CW6180+) | Patsogolo 21mitundu,Kusintha12mitundu | |||

| Kuthamanga kwa spindle (Nambala) | 14-750RPM(MATSANZO 18) | ||||

| GEAR BOX-THREADS & FEED | 44mitundu 1-120mm | ||||

| Mtundu wa ulusi (mitundu) | 1-240mm (54 mitundu) | 31 mitundu 1/4-24 T/I | |||

| Inchi ulusi rang (Mitundu) | 28-1 inchi (36 mitundu) | 45mitundu 0.5-60 mm | |||

| Mitundu ya ulusi wa Module (mitundu) | 0.5-60 DP (27 mitundu) | 38mitundu 1/2-56DP | |||

| Mitundu ya ulusi wa Diametral (mitundu) | 30-1 tpi (27 mitundu) | 56 mitundu 0.1-12mm | |||

| Zakudya zazitali (mitundu) | 0.048-24.3mm/r (mitundu 72) | 56mitundu 0.05-6mm | |||

| Cross feed range (mitundu) | 0.024-12.15mm/r (mitundu 72) | 3400mm/mphindi, 1700mm/mphindi | |||

| Zakudya zofulumira:Zamtali./Cross | 4/2m/mphindi | ||||

| Kukula kwa Leadscrew: Diameter / Pitch | T48mm/12mm OR T55mm/12mm (kwa 5M+) | 48 mm pa | |||

| NYAMA YONYAMATA | 45 * 45mm | ||||

| Ulendo wodutsa pazithunzi | 350 mm | 420 mm | 520 mm | ||

| Ulendo wopumula wophatikiza | 200 mm | 650 mm | |||

| Kukula kwa shank chida | 32 * 32 mm | 280 mm | |||

| Mtengo wa TAILSTOCK | |||||

| Diameter ya spindle | 100 mm | 120 mm | Φ160 mm | ||

| Spindle taper | MZIMU #6 | Metric 80# | |||

| Kuyenda kwa spindle | 240 mm | 300 mm | |||

| MOTOR | |||||

| Main drive motor | 11kw pa | 22kw pa | |||

| Pampu yamoto yoziziritsa | 0.09kw | 0.15kw | |||

| Rapid feed motor | 1.1kw | 1.5kw | |||

Nthawi yotumiza: Apr-14-2022