Chitoliro ulusi lathe amatchedwansodziko la mafuta,kutembenuza ulusi kumatanthawuza njira yopangira ulusi pa chogwirira ntchito ndi chida chopangira, makamaka kutembenuza, mphero, kugogoda, ulusi ulusi, kugaya, ndi kudula kamvuluvulu. Potembenuza, mphero ndi ulusi wopera, unyolo wotumizira wa chida cha makina umatsimikizira kuti chida chotembenuza, chodula mphero kapena gudumu lopukuta chimayenda molondola komanso molingana ndi olamulira a workpiece ndi chitsogozo chimodzi pakusintha kulikonse kwa workpiece. Pogogoda kapena ulusi, chida (pampopi kapena kufa) chimazungulira chogwirizana ndi chogwiritsira ntchito, ndipo choyamba chopangidwa ndi ulusi chimatsogolera chida (kapena chogwirira ntchito) kuti chisunthe axially.

Ndipo chomwe timayang'ana kwambiri ndikutembenuza ulusiulusi wa payipi lathes. Chida chopangira ulusi kapena chipeso cha ulusi chingagwiritsidwe ntchito kutembenuza ulusi pa ulusi wa chitoliro. Kutembenuza ulusi ndi chida chokhotakhota, chida chozengereza ndi chosavuta, ndi njira wamba yopangira ma batch ang'onoang'ono ndikukonza zida zopangira ulusi. Kutembenuza ulusi ndi chida chopangira ulusi kumakhala bwino kwambiri, koma mawonekedwe a zida ndi ovuta, ndipo ndi oyenera kutembenuza zingwe zazifupi za ulusi wapakatikati komanso zazikulu.

Kulondola kwa phula kwa lathes wamba potembenuza ulusi wa trapezoidal nthawi zambiri kumatha kufika 8-9, koma kupanga bwino komanso kulondola kwa akatswiri.CNC chitoliro ulusi makinaadzakhala bwino kwambiri.

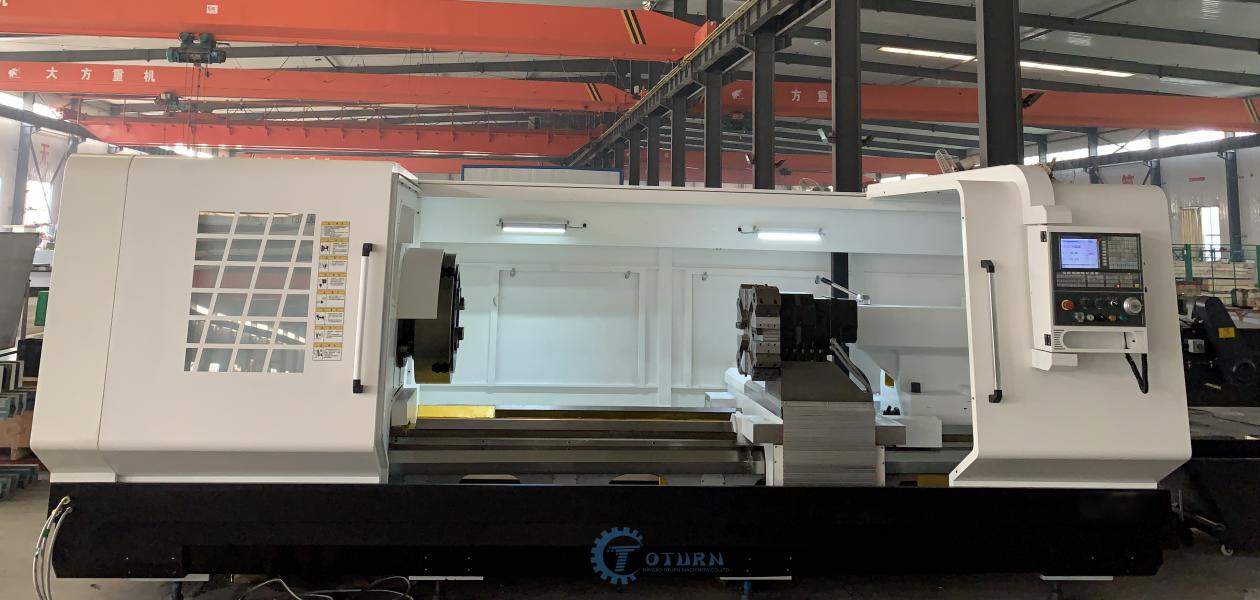

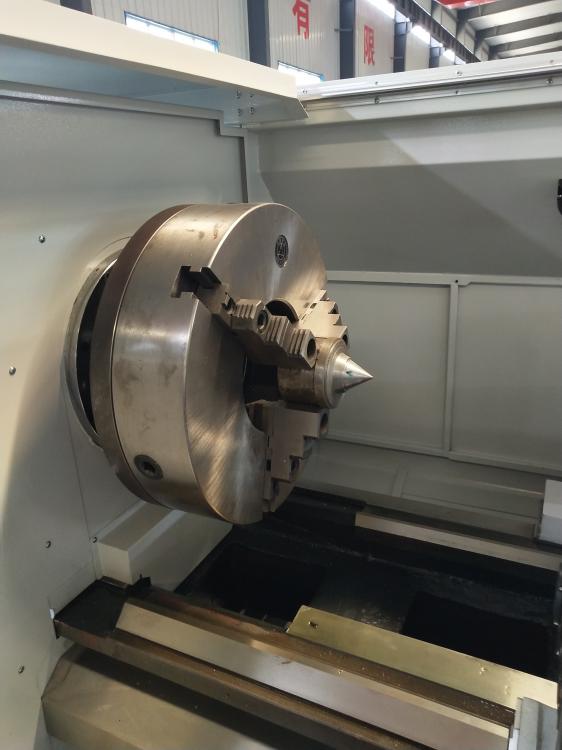

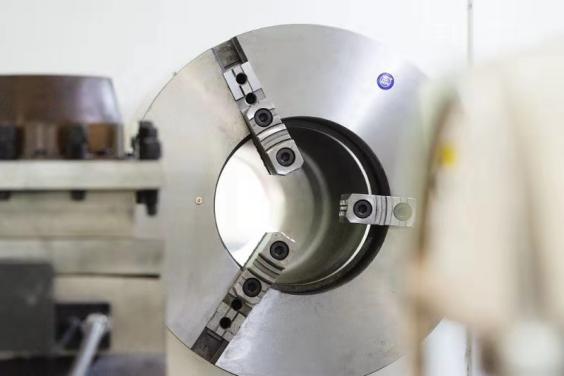

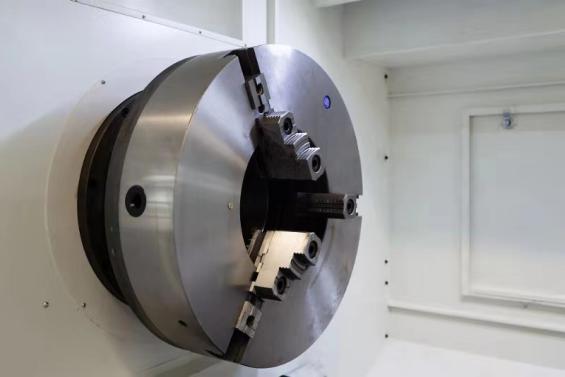

Chitoliro chopangira lathemakinandi lathe yopingasa mwapadera kuti atembenuzire zazikulu m'mimba mwake chitoliro zovekera. Amadziwika ndi kukula kwa dzenje la spindle (nthawi zambiri kuposa 135mm) ndi chuck kutsogolo ndi kumbuyo kwa bokosi la spindle. , Kuti atsogolere clamping ndi processing wa mipope lalikulu m'mimba mwake kapena ndodo.

Dziko lamafutalathemakinaNthawi zambiri amakhala ndi bowo lalikulu pabokosi la spindle, ndipo chogwirirapo chimangiriridwa ndi ma chuck awiri kumapeto onse a spindle kuti azungulire akadutsa bowolo. Pali njira ziwiri zodyetsera chida: imodzi ndi yofanana ndi lathe wamba ndi wononga kutsogolera kuyendetsa slide ndi chogwirizira kutsogolo kwa bedi; china ndi chisa chathyathyathya pa slide pakatikati pa bedi. Mutu wakunja wodula ulusi wa mpeni (onani ulusi wongotsegula ndi kutseka wodula mutu) umadula mu workpiece ndikupita patsogolo. Zida zina zamakina zopangira mapaipi aatali zimakhalanso ndi zida zothandizira, monga chimango chapakati, chopumira cha zida, ndi bulaketi yakumbuyo.

CNC chitoliro ulusi lathelimbikitsa

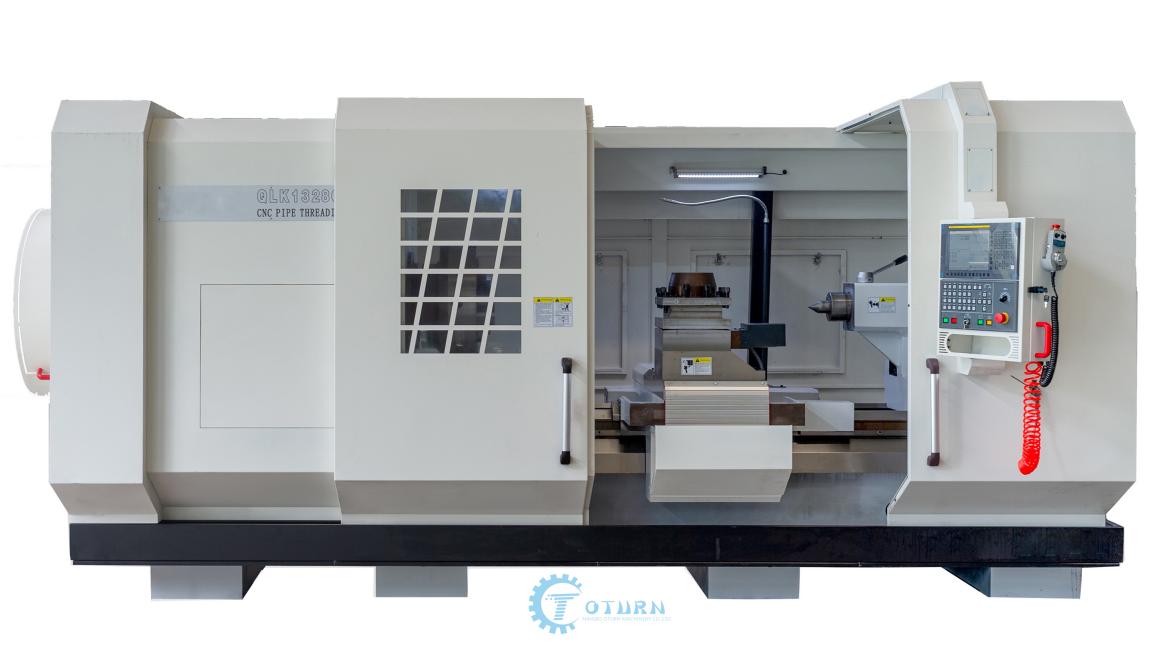

QLK1315 / QLK1320 / QLK1323 / QLK1325 / QLK1328 / QLK1336 / QLK1345 / QKL1353 / QLK1363

QLK1320

Makhalidwe awapamwamba kwambiripayipi yopangira lathe:

1. Bedi liri ndi mapangidwe oyambirira a khoma lazitsulo zitatu, ndipo khoma lakumbuyo limakonzedwa ndi ndege ya 12-degree, yomwe imathandizira kwambiri kulimba kwa chida cha makina.

2. Njira yayikulu yopatsirana ndikutumiza kwamagulu, komwe kumachepetsa kugwiritsa ntchito mphamvu ndi phokoso la chida cha makina.

3. Kugwiritsa ntchito mabokosi osiyana a hydraulic, mafuta opaka pakati, ndi kuziziritsa kwamphamvu sikungochepetsa kutentha kwa spindle komanso kumasunga ukhondo ndi mafuta a bokosi la spindle.

QLK1336

QLK1336CNC Dziko la mafuta lathendi wapangidwa kumene CNC chitoliro threading lathe. Choyendetsa chachikulu chapangidwa kuti chifanane ndi kuchuluka kwa magwiridwe antchito amtundu wosankhidwa wa spindle servo motor. Full stepless liwiro malamulo, lonse liwiro malamulo osiyanasiyana, amene osati umakwaniritsa zofunika mkulu-liwiro ulusi kutsirizitsa, komanso ali mkulu kudula dzuwa ndi otsika phokoso.

Ubwino ndi ubwino wa zitoliro threading lathes

(1) Thupi la makina

M'lifupi mwa njanji ya thupi ndi 650mm, zinthu ndi HT300. Ultrasonic frequency quenching ikufika ku HRC52.Kuvuta kwake ndi Ra0.63 pambuyo popukutidwa ndi makina opukutira apamwamba kwambiri. Thupi la makina ndi gawo lofunikira, lomwe limathandizira kwambiri kulimba kwa chida cha makina.

(2)CNC mafuta dziko machinesMutu Bokosi

Integral gear box type spindle unit, high power spindle servo motor,

Awiri-liwiro kufala, stepless liwiro lamulo.

Kuthamanga kosiyanasiyana kwa kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kake kake

Bokosi la spindle limagwiritsa ntchito mafuta oziziritsa akunja ozungulira,

sikuti amachepetsa kutentha kwa spindle, komanso amasunga ukhondo ndi mafuta a spindle box.

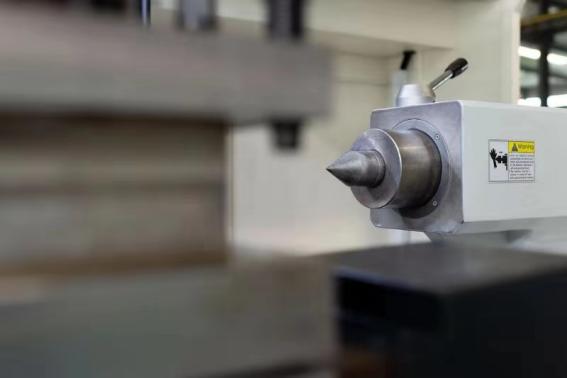

(3)Mchira

Chida cha makina ichi ndi chokhazikika ndi φ120 tailstock spindle. Mohs 6 # pamwamba.

(4)Kudyetsa kawiri-axis

Ma X axis ndi Z axis amatengera kulondola kwambiri kwa mpira wononga drive molunjika komanso mawonekedwe olimba a screw prestress. Zovala zomata bwino za mpira zimagwiritsidwa ntchito poyika ndikuthandizira; Z shaft screw nati rack ndi gawo lofunikira poponya.

(5) CNC Turret

Adopts (HAK21280) CNC ofukula chida chofukizira. Zili ndi makhalidwe olondola kwambiri, kuzungulira kosalala, ntchito yosavuta ndi zina zotero.

Zifukwa zinayi zoti musankheCNC chitoliro ulusimachine kapenamafuta opangira makina opangira mafuta

1.Thelathe ulusi wa pipeali ndi mawonekedwe a digiri yapamwamba yodzipangira okha, kuchita bwino kwambiri komanso kulondola kwambiri, kugwiritsa ntchito mosiyanasiyana, komanso kugwira ntchito kosavuta.

2.Bokosi la bedi limayendetsedwa ndi injini yosinthira pafupipafupi, ndikusintha kwa liwiro lopanda mayendedwe. Mapiritsi a spindle ochokera kwa opanga odziwika bwino apakhomo, nsagwada zitatu za chucks kuchokera kuzinthu zodziwika bwino zapakhomo.

3.Mapangidwe amtundu wa ndondomeko yoyendetsera chiwerengero ndi yosavuta kusokoneza komanso yosavuta kusamalira. Nkhwangwa za x ndi z zimatengera mphamvu zapamwamba, ma servo motors, magwiridwe antchito apamwamba, komanso kudalirika kolimba.

4.Imatengera chishalo cha bedi, mbale yotsetsereka, kapangidwe ka nthiti zamkati, zomangira zolondola kwambiri za mpira, kulondola kwambiri, komanso kutumiza kolondola.

Zithunzi Zazigawo Zazikulu

Kusintha kokhazikika

Positi ya zida zamagetsi zokhala ndi masiteshoni anayi, kuthira mafuta apakati, makina ozizirira, chivundikiro chotchinga chotchinga.

Izi zimagwiritsidwa ntchito kwambiri pamakina opangira makina opanga makina, mafuta, mankhwala, malasha, kufufuza kwa geological, madzi am'tawuni ndi ngalande, ndi mafakitale ena.

Zigawo zazikulu zotsalira zikuphatikizapokubowola mapaipi ndi couplings.

Makampani a petroleum ndi gawo la mafakitale omwe amachotsa mafuta amafuta (kuphatikiza mafuta achilengedwe, shale yamafuta, ndi gasi) ndikuwongolera ndikuwongolera. Amapangidwa ndi kufufuza kwa geological field, oilfield development and mafuta, mayendedwe, kuyenga ndi kukonza magawo.

Mawu omwe amagwiritsidwa ntchito kwambiri potengera machubu m'makampani amafuta ndi gasi ndi Petroleum Tubing (OCTG). Zolinga zamapaipi a petroleum zitha kukhala zosiyana: zitha kugwiritsidwa ntchito kutulutsa kapena kubaya gasi, mafuta, madzi, nthunzi, ndi zina zambiri, ndipo zitha kugawidwa m'mabokosi kapena machubu malinga ndi ntchito zina. Casing imagwiritsidwa ntchito ngati chitetezo chothandizira zitsime zamafuta kukana kukokoloka kwa zoipitsa zamkati kapena zakunja kuti zikhale zolimba; chubu amagwiritsidwa ntchito kubaya kapena kuchotsa mafuta.

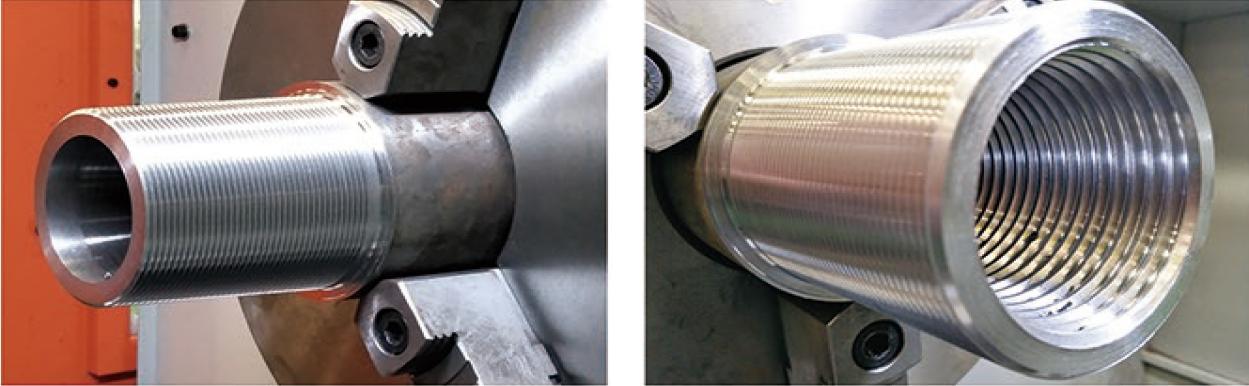

Ulusi wa chitolirondi zida zamakina amagwiritsidwa ntchito pokonza mapaipi amafuta, omwe amagwiritsidwa ntchito kwambiri m'makampani amafuta. Ndi chitoliro chachitsulo chomwe chimagwiritsidwa ntchito kunyamula mafuta ndi gasi m'zitsime zamafuta. Imayikidwa m'bokosi, ndipo mafuta ndi gasi zimayenda kuchokera papaipi yamafuta kupita pachitsime.

Pali miyeso iwiri ya ulusi wa chubu, umodzi ndi ulusi wa taper wooneka ngati V wokhala ndi dome mozungulira pansi ndi mano 8 pa inchi, ndipo winayo ndi ulusi wa chitoliro chooneka ngati V wokhala ndi dome pansi pa mano 10 pa inchi.

Ulusi ndi kutuluka kosalekeza komwe kumapangidwa ndi dzino lopangidwa motsatira mzere wozungulira pamwamba pa silinda kapena chulucho. Pali njira zambiri zopangira ulusi wamakina, ndipo ulusi nthawi zambiri umagwiritsidwa ntchito pamakina wamba. Litimakina ulusipa lathe yopingasa, mgwirizano woyenda pakati pa workpiece ndi chida uyenera kutsimikiziridwa. Mu zenizenikutembenuka kwa ulusi, chifukwa cha zifukwa zosiyanasiyana, kusuntha pakati pa spindle ndi chida kumakhala ndi zovuta pa ulalo wina, zomwe zimayambitsa kulephera panthawi yokhotakhota ndi kukhudza kupanga bwino. Panthawi imeneyi, iyenera kuthetsedwa panthawi yake.

Momwe mungathetsere vuto la roughness lalikulu, zotsatirazi ndi malingaliro a ena odziwa bwino chitoliro cha ulusi lathe:

1. Mukatembenuka ndi chida chosinthira chitsulo chothamanga kwambiri, liwiro lotembenuka liyenera kuchepetsedwa ndipo mafuta otembenuza ayenera kuwonjezeredwa.

2. Wonjezerani gawo la mtanda wa arbor ndikuchepetsa kutalika kwa kutalika (chifukwa arbor siili yolimba mokwanira, imakonda kugwedezeka panthawi yodula)

3. Chepetsani mbali yakutsogolo ya chida chokhotakhota ndikusintha chilolezo cha screw nut ya mbale yapakati ya slide (mbali yakutsogolo ya chida chotembenuza ndi yayikulu kwambiri, ndipo chilolezo cha slide screw nut ndi yayikulu kwambiri, zomwe zidzapangitse chida mosavuta)

4. Ulusi wothamanga kwambiri ukatembenuka, makulidwe otembenuza omaliza amakhala okulirapo kuposa 0.1mm, ndipo tchipisi tating'ono ting'onoting'ono timatayidwa motsatana ndi mbali ya axis (pamenekutembenuka kwa ulusi wothamanga kwambiri, makulidwe otembenuzika ndi ochepa kwambiri kapena tchipisi tating'onoting'ono tating'onoting'ono tating'onoting'ono, ndikosavuta kukoka ulusiwo).

5. Mafuta opopera apamwamba kwambiri kapena mafuta otembenuza lathe okhala ndi wothandizila kwambiri ayenera kugwiritsidwa ntchitokonza ulusiza workpiece kupyolera mu lathe. Kugwiritsa ntchito mafuta apadera opangira zitsulo kungapangitse vuto la kusalondola bwino komanso kuchepa kwachangu.

Nthawi yotumiza: Sep-21-2021