TheMakina apadera a Valveamagwiritsidwa ntchito makamaka pokonza Vavu (Vavu yagulugufe / Chipata valavu / Vavu ya Mpira / valavu yapadziko lonse, etc ..), Pampu thupi, Zigawo za Auto, Zida zamakina omanga etc.

Imagwira ntchito zosiyanasiyana zosiyanasiyana, monga: Mapeto a nkhope, bwalo lakunja, m'mphepete kutsogolo, dzenje lamkati, grooving, Screw thread, Bore-hole ndi Sphere. Itha kuzindikira zodziwikiratu, zolondola kwambiri, zosiyanasiyana komanso zopanga zambiri. Zogwiritsidwa ntchito kwambiri pamakina a valve.

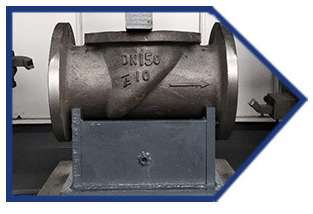

Mavavu ndi zida zamapaipi zomwe zimagwiritsidwa ntchito kutsegula ndi kutseka mapaipi, kuwongolera kuyenda, kusintha ndi kuwongolera magawo (kutentha, kuthamanga, ndi kutuluka) kwa sing'anga yotumizira. Malinga ndi ntchito yake, imatha kugawidwa kukhala valve yotseka,chekeni valavu, valavu yowongolera, ndi zina zotero.

Valve ndi gawo lowongolera mumayendedwe amadzimadzi. Lili ndi ntchito zodula, kuwongolera, kusokoneza, kupewa kuyenderera m'mbuyo, kukhazikika, kusokoneza kapena kusefukira, komanso kuchepetsa kupanikizika. Mavavu omwe amagwiritsidwa ntchito m'makina owongolera madzimadzi, kuyambira ma valve osavuta otsekera mpaka ma valve osiyanasiyana omwe amagwiritsidwa ntchito m'makina ovuta kwambiri owongolera, amakhala ndi mitundu yosiyanasiyana komanso mawonekedwe.

Mavavu amagwiritsidwa ntchito kwambiri m'magawo osiyanasiyana. Makamaka mafuta, zitsulo, mphamvu yamagetsi, kusungirako madzi, kumanga m'tawuni, kuzimitsa moto, makina, malasha, chakudya, etc.

Kupezeka

Ubwino wake ndi chiyaniMakina apadera a Valvem'makampani a valve

√Kubowola kumatengera mtundu wa ma axis angapo, ndipo magwiridwe ake amasinthidwa kangapo.

√Kupindula mitu iwiri kapena itatu processing nthawi imodzi pa processing kuzindikira standardization ndi mkulu dzuwapompa chitoliro valavu processing.

√Njira yowongolera manambala yokhayokha, yokhazikika yokhazikika.

Makina athu ovomerezeka a Special Valve

Malangizo athudMakina apadera a Valve

1.Makina thupi

Thupi la Machine limapangidwa ndi kuponyedwa kwachitsulo chambiri chotuwira, kukonza mwankhanza, kumaliza, ndi machiritso atatu okalamba kuti athetse kupsinjika kotsalira. Pamwamba pa njanji yowongolera

Imatengera chithandizo chozimitsa ma audio pafupipafupi ndipo imakonzedwa ndi njanji yolondola kwambiri kuti iwonetsetse kulondola, kusasunthika, komanso kukhazikika kwa chida cha makina. √

2.Makina apadera a Vavu

Mutu Bokosi

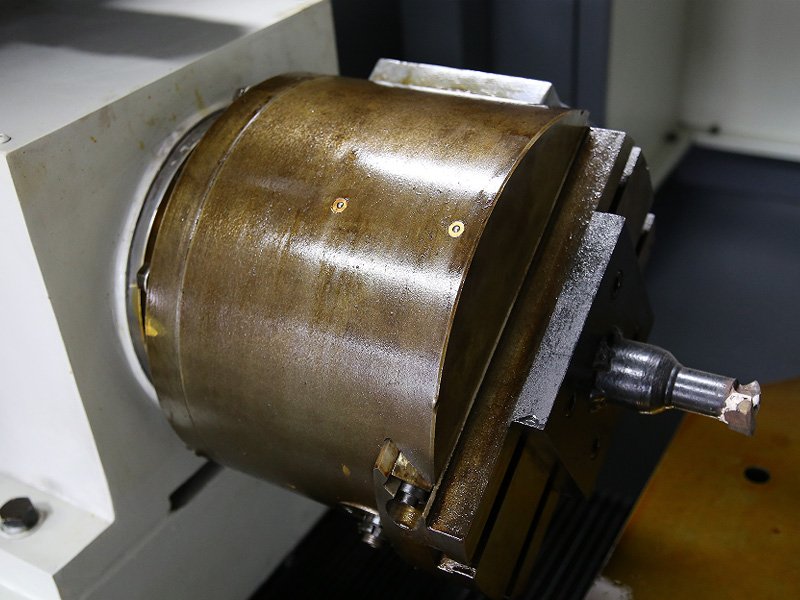

Bokosi la Mutu limapangidwa ndi ma castings apamwamba kwambiri, ndipo shaft yaikulu imapangidwa ndi 20GrMnTAi, yomwe yapangidwa, yotsekedwa, yotsekedwa, ndi yowopsya, yamoto ndi yozimitsidwa, ndikuwonjezeredwa ndi chopukusira chapamwamba chamkati ndi kunja kwa cylindrical.

Chonyamuliracho chimakhala ndi mizere yolondola kwambiri ya mizere iwiri ya cylindrical kuti zitsimikizire kulimba komanso kulondola kwa spindle. Shaft yayikulu imatenga kusintha kwa magawo atatu ndi injini yamphamvu kwambiri kuti ikwaniritse liwiro lotsika

Makokedwe akulu, amatha kunyamula katundu wodula kwambiri, kukonza magwiridwe antchito. √

7. chipangizo chapakati mafuta

Dongosolo lopaka mafuta lili ndi chipangizo chopangira mafuta cha Nanjing Beqier, chomwe nthawi zonse chimapopera mafuta opaka m'malo opaka gawo lililonse lomwe likuyenda, ndikuchotsa ntchito yotopetsa yamanja.

Sinthani moyo wautumiki wa chida cha makina. √

Makina awiri a CNC

Gulugufemakina apadera a valve

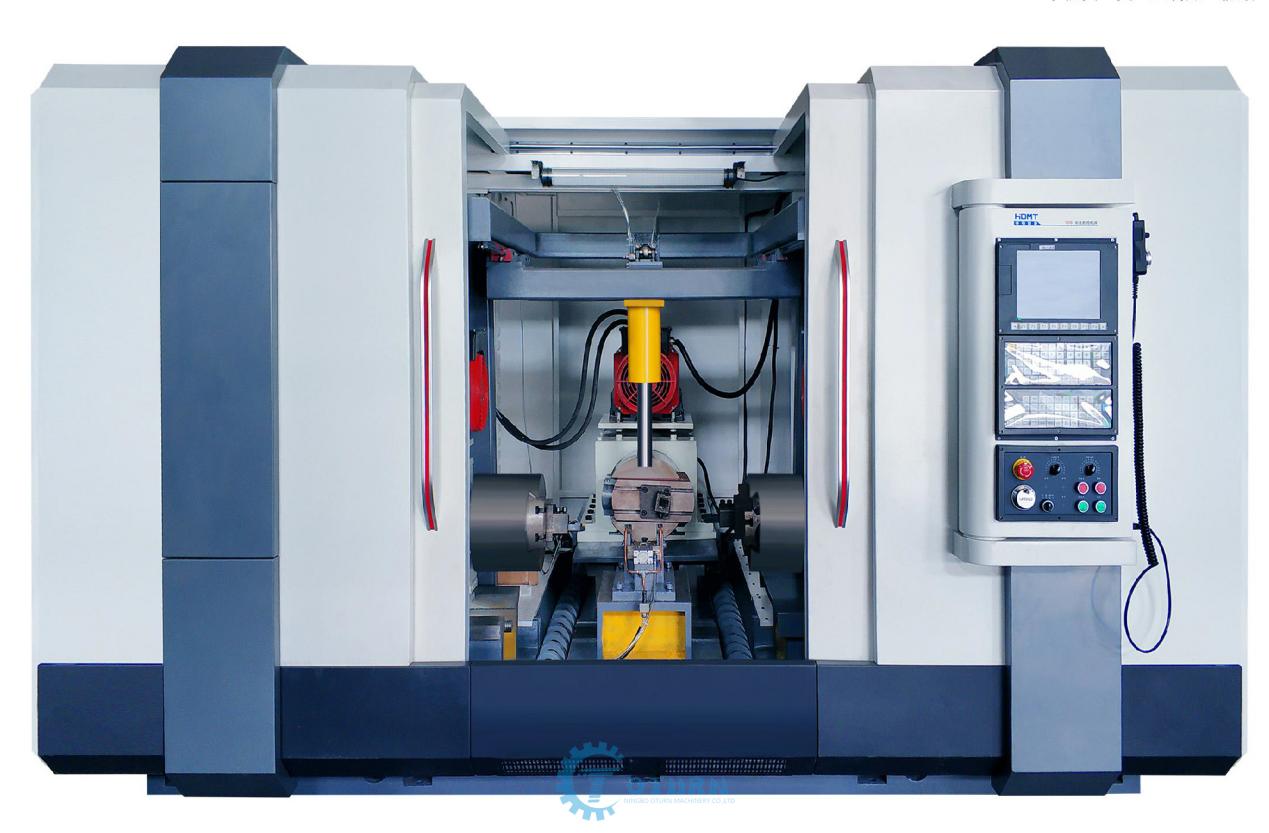

HDCX800 kutembenuza-mphero gulu Machining center,valavu ya butterflychida chapadera chopangira makina chimagwiritsidwa ntchito makamaka mu mavavu agulugufe ndi ziro

Pakukonza magawo, makina a uinjiniya ndi magawo ena, nkhope yomaliza, bwalo lakunja, spigot, dzenje lamkati, poyambira, ulusi, dzenje la taper ndi mawonekedwe ozungulira a workpiece amatha kukonzedwa.

Kutembenuka. Kukonzekera kumayendetsedwa ndi GSK CNC system, yomwe imatha kuzindikira zodziwikiratu, zolondola kwambiri, zamitundumitundu, komanso kupanga zambiri.

chachikulu mbali

1. Makina a HDCX800 Special Valve onse amayendetsedwa ndi GSK CNC system, yomwe imatha kuzindikirika ndi kulumikizana kwapawiri-axis.

Kukonza mabowo a taper, ulusi, ndi njira zozungulira. Dongosolo lake la CNC ndi logwirizana, lamphamvu, komanso losavuta kugwiritsa ntchito.

2. Njanji yolondolera ya slide ya chakudya imapangidwa ndi chitsulo chamtengo wapatali chotuwa, chomwe chakhala chikuthandizidwa ndi machiritso atatu okalamba pambuyo pochita roughcast ndikumaliza kuti athetse kupsinjika kotsalira kwamkati.

Kumtunda kumatenga chithandizo chozimitsa ma audio pafupipafupi ndipo kuuma kumafika pa HRC55. Kulondola, kusasunthika, komanso kukhazikika kwa chida cha makina kumatsimikiziridwa ndi kugaya kolondola kwambiri kwa njanji.

3. Zigawo zopatsirana zimayendetsedwa ndi zomangira zolondola za mpira ndipo njira zomasulira zimagwiritsidwa ntchito kuthetsa mipata, kuonetsetsa kuti kufalikira ndi kukonza makina opangira makina.

4. Mutu wamagetsi umagwiritsa ntchito njira zitatu zotumizira mauthenga ndi injini yamphamvu kwambiri kuti ikwaniritse zothamanga kwambiri komanso zothamanga kwambiri, zimatha kupirira katundu wodula kwambiri, ndikuwongolera kukonza bwino.

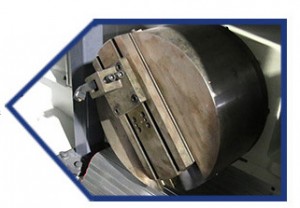

5. Zidazi zimagwiritsa ntchito hydraulic automatic clamping kuti ziwongolere bwino komanso kuchepetsa kuchuluka kwa ntchito.

6. HDCX800 Special Valve Machine,valavu gulugufe makina apadera processingchida utenga kondomu pakati kuonetsetsa kuti gawo lililonse kusuntha ndi mafuta mokwanira ndi kukonza makina chida.

Makina apadera a Valve Kapangidwe

Mutu Wamphamvu

Thupi lamutu lamutu lamphamvu limapangidwa ndi zida zapamwamba kwambiri, ndipo shaft yayikulu imapangidwa ndi zinthu za 20GrMnTAi, zomwe zimakonzedwa ndikuzimitsa, kuzimitsa, ndikuwotcha, kuzimitsa, kuzimitsa, ndi kuzimitsa, komanso zopukutira zamkati ndi zakunja zamkati.

Chovalacho chimatengera NN30 mndandanda wolondola kwambiri wa mizere iwiri ya cylindrical roller kuti zitsimikizire kukhazikika komanso kulondola kwa spindle.

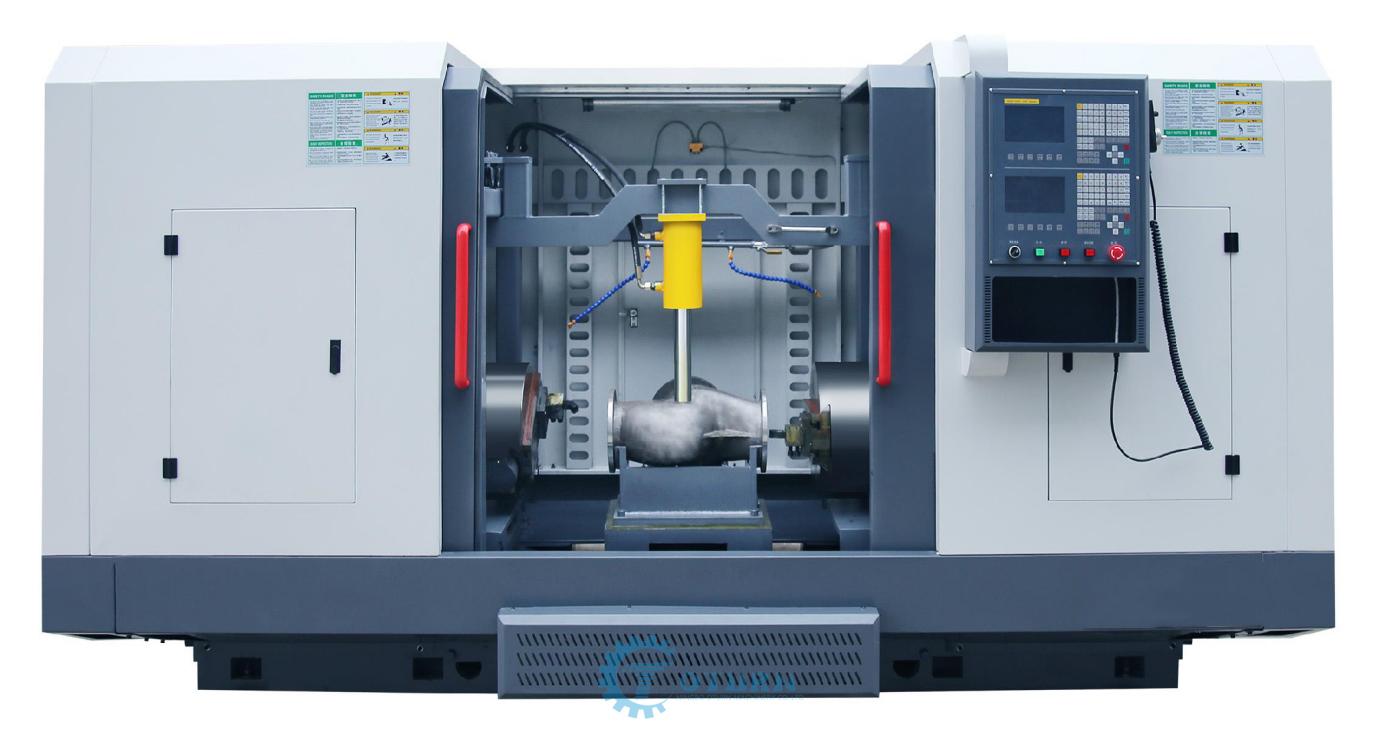

Ntchito

The worktable ndi workbench yapadera yopangidwa mwapadera malinga ndi magawo okonzedwa. Mipiringidzo ndi zikhomo zoyika zonse zimazimitsidwa kuti zitsimikizire malo odalirika a workpiece.

Kuphatikizika kwa workpiece kumatengera kuwongolera pamanja kuti kuwongolera magwiridwe antchito ndikuchepetsa kuchuluka kwa ntchito. Ndipo worktable akhoza zisinthasintha madigiri 180, nthawi imodzi clamping, nthawi imodzi Malizitsani njira zonse.

Makina osinthira chida chosinthira magazini

Kwathunthu basi CNC chida chosinthira chida magazini, amene angathe kugwira 16 zida, 20 zida, 24 zida, etc., amene basi kulamulidwa ndi dongosolo, ndi mofulumira chida kusintha liwiro ndi kulondola zolondola.

- Mutu wamphamvu

Mutu wamagetsi umatenga mawonekedwe apadera a motor + screw screw, omwe ali ndi mawonekedwe olondola kwambiri, olimba kwambiri, komanso moyo wautali.

- Zida

-

The tooling ndi chida chapadera chopangidwa mwapadera malinga ndi mbali zomwe ziyenera kukonzedwa. Mipiringidzo ndi zikhomo zoyika zonse zimazimitsidwa kuti zitsimikizire malo odalirika a workpiece. Chogwirira ntchitocho chimamangidwa ndi hydraulic clamping, yomwe imathandizira kukonza bwino komanso kumachepetsa mphamvu ya ogwira ntchito.

- Kabati yamagetsi

Kabati yamagetsi imatenga mtundu wodziyimira pawokha wotsekedwa, wokhala ndi makina owongolera, osinthira pafupipafupi komanso magawo amagetsi owongolera ndege, ndipo amakhala ndi zida zoziziritsa mpweya kuti zitsimikizire kuti zida zamagetsi za chida cha makina zimagwira ntchito bwino komanso sizilowa fumbi.

- CNC Control System

Lili ndi ntchito zaukadaulo wowongolera njira zambiri, makina opangira ma axis asanu, kuthamanga kwambiri komanso kulondola kwambiri, kutembenuka ndi mphero, kuwongolera kolumikizana ndi kuwongolera kwina kwapamwamba kwa CNC.

Kusankha zida:

Kuwongolera kwa CNC

kuziziritsa kulamulira

Makina oyendetsa chip

Theka chitetezo / chitetezo chokwanira

Kwa mitundu yosiyanasiyana ya ma valve, njira zosiyanasiyana zimakonzedwa. Mwachitsanzo, ntchito zopanga ndi zokonzekera zosiyanasiyana zaukadaulo ziyenera kupangidwa musanakonze. Akatswiri amayenera kukonzekera molingana ndi kapangidwe kazinthuzo komanso zida zapadera zopangira ndege ya Huadian valve. Ma valve opanda kanthu amatha kupangidwa ndi kuponya mchenga, kuponyera mwatsatanetsatane kapena kuponyera sera popanga. Pakupanga kapena kuwotcherera, ndikofunikira kupanga molingana ndi zomwe zilibe kanthu.

Thendondomeko za valve processingndizovuta, ndipo mtengo wowonjezera wa mankhwalawa ndi wotsika. Ubwino wogwiritsa ntchito wamba kapenaCNC makina zidasizingawonekere. Kukonzekera kwathunthu kwa valve kumafuna kuphatikiza makina angapo kuti akwaniritse zotsatira zake. Nthawi iliyonse mukasintha kukula kapena kusiyanasiyana, muyenera kusintha chida cha makina, ndiyeno sinthani njira yomalizidwa kuchokera panjira yapitayi kupita ku chida chofananira cha makina munjira yotsatira. Izi sizimangowonjezera mtengo wopanga, komanso zimawononga nthawi yambiri. Nthawi zambiri, zida zogwirira ntchito zomwe zimafunikira kulondola kwambiri, chifukwa chakusintha kangapo kangapo, zimawonjezera cholakwika cha chogwiriracho. Choncho ubwino wandege ya valvezimadziwikiratu.

Mwachitsanzo, kwama valve pachipata, kutembenuza kwa ma flanges a mbali zitatu kungatheke pa makina amodzi. Pakalipano, makina apadera a HDMT valve amatha nthawi imodzi kupanga mbali ziwiri kapena zitatu za valve flange panthawi imodzi, zomwe zimakhala zosavuta komanso zogwira mtima, pamene kupanga chikhalidwe Chokhachokha cha valve chikhoza kukonzedwa panthawi imodzi, chomwe chimatenga nthawi. ndi olimbikira ntchito. Momwemonso, kubowola kwa flange kumbali zitatu kapena ziwiri za valve kumachokeranso pa mfundo yomweyi, yomwe sikuti imangowonjezera bwino, komanso imachepetsanso kulolerana kwa dzenje.

Zochita zamakina apadera a valveNdiwosavuta kwambiri, zitsanzo zonse zazindikira kapangidwe kake, zimangofunika kulowetsa magawo. Izi zimachepetsa kwambiri ntchito zamanja, zimachepetsa ndalama zogwirira ntchito, komanso zimapulumutsa nthawi ndi khama. Ngati pali kuchulukirachulukira kapena vuto lina likachitika panthawi yopanga, makinawo amapereka alamu mwachangu kapena kutseka basi, kuti apewe kuwonongeka kwa makina kwambiri.

Ndege ya valavu ikatha, wogwiritsa ntchitoyo azimitsa magetsi ogwirizana nawo, agwire ntchito yabwino yoyeretsa, ndikugwiritsa ntchito mafuta odziwa ntchito kukonza ndi kukonza ndege ya valve. Pali zinthu zambiri zomwe zimafunika kuziganizira panthawi yogwiritsira ntchito makina apadera a valve. Makina apadera a valve sangathe kuchita ntchito monga kusintha kwa zida, kuyang'ana ndi kuchotsa panthawi ya ntchito. Panthawi yonse ya ntchito ya makina apadera a valve, ogwira ntchito ndi ogwira ntchito sayenera kusiya ntchito zawo, ndipo ayenera kuchita ntchito yabwino yoyang'anira. Zida monga zogwirira ntchito, zomangira, ndi mipeni ziyenera kumangidwa mwamphamvu, apo ayi mavuto ena ndi kayendedwe ka workpiece adzachitika. Kuchita bwino kungayambitse kuvulala kosafunikira. Ngati mpeni wathyoka kapena wathyoka, uyenera kusinthidwa pakapita nthawi. Pogwira ntchito yachibadwa, sitingathe kukhudza mwachindunji pamwamba pa ntchitoyo ndi manja athu, komanso sitingathe kuchotsa mwachindunji zinthu zoopsa monga kudula ndi manja athu. Izi sizidzangovulaza manja athu, komanso zimapangitsa kuti zitsulo zachitsulo ziwuluke. Ngozi m'maso. Pa nthawi ya ntchito yandege yapadera ya valve, muyenera kuvala maovololo oyenerera, kuvala chipewa chogwirira ntchito, ndipo onetsetsani kuti mwayika tsitsi lanu mu kapu yogwirira ntchito. Mukatsitsa ndikutsitsa zida zazikulu zogwirira ntchito, yesani kugwiritsa ntchito zida zonyamulira, kuti ntchito yonseyo ikhale yogwirizana mwaukadaulo, ndipo chitetezo chizikhala chokwera.

Nthawi yotumiza: Sep-22-2021