Kodi makina obowola ndi mphero a CNC ndi chiyani:

CNC pobowola makinandi zida zachitsulo zodulira makina, ndi ntchito za kukonza dzenje, kubowola, kugogoda, kusangalatsa komanso mphero wothandiza. Amagwiritsidwa ntchito kwambiri pobowola bwino kwambiri mbale zathyathyathya, ma flanges, ma disc, mphete, ndi zida zina zogwirira ntchito zomwe makulidwe ake ali mkati mwazothandiza.

Kubowola m'mabowo ndi mabowo akhungu kumatha kuzindikirika pazigawo zakuthupi limodzi ndi zida zophatikizika. Makina opangira makina amawongoleredwa ndi digito, ndipo ntchitoyo ndi yabwino kwambiri. Imatha kuzindikira makina, kulondola kwambiri, mitundu ingapo, komanso kupanga zambiri.

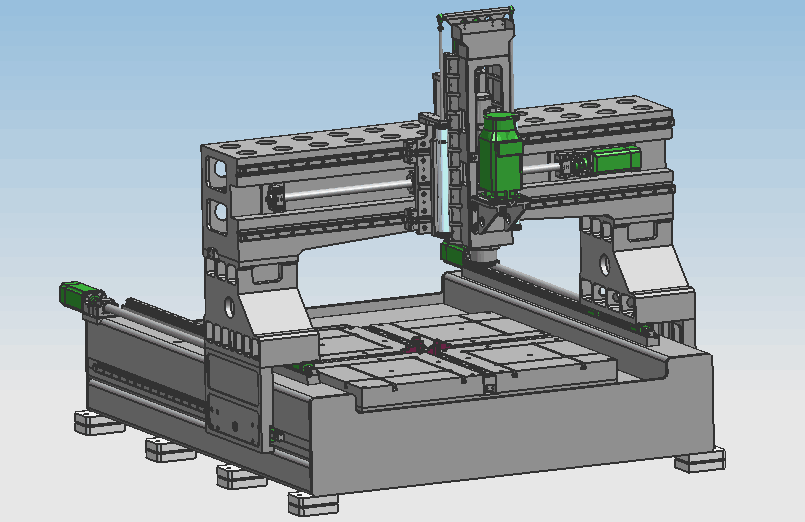

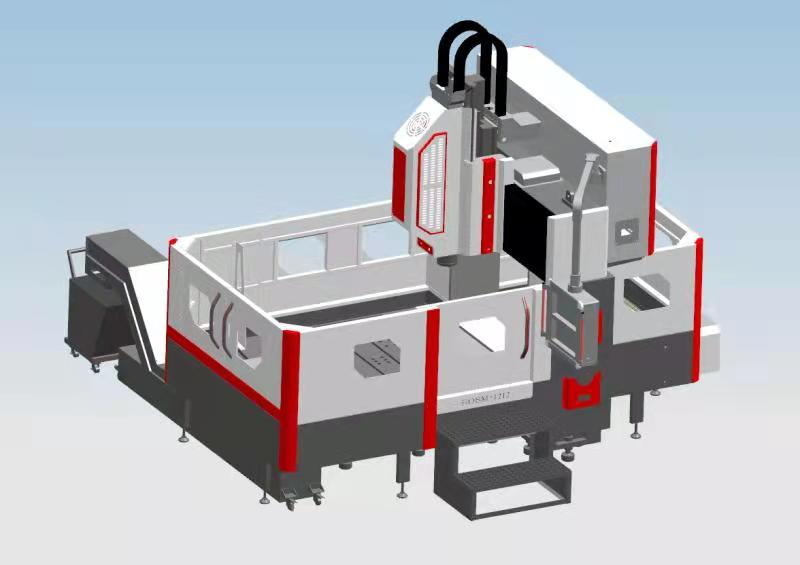

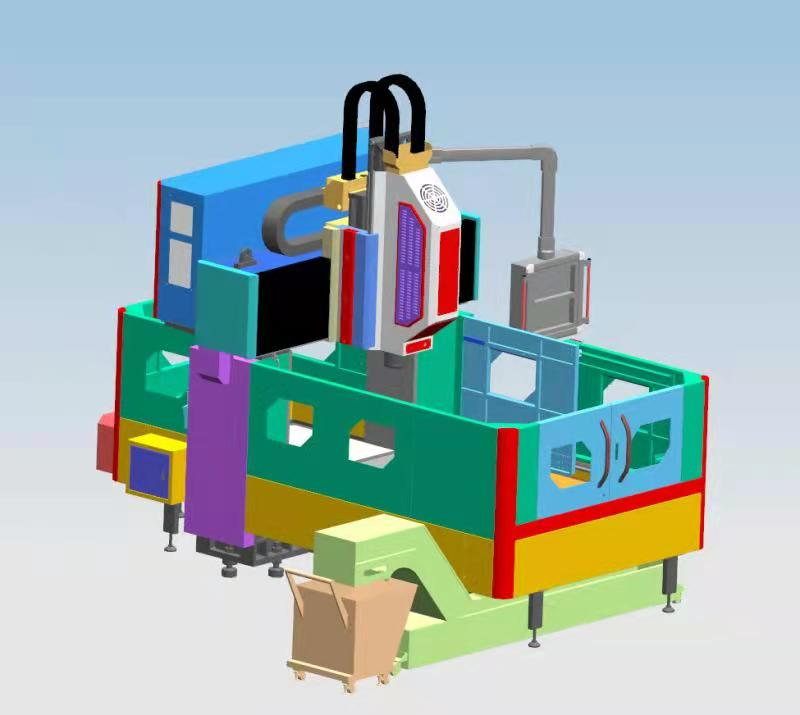

CNC pobowola ndi mphero makinazida kapangidwe

1.Bedi:

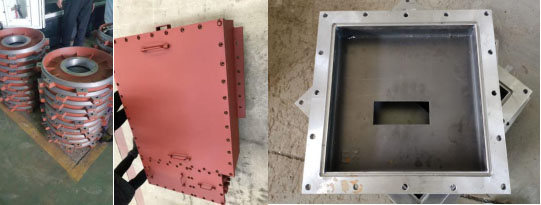

Bedi ndi gawo lofunikira kwambiri, lomalizidwa ndi chithandizo chachiwiri cha annealing, chokhazikika komanso chokhazikika komanso chosasinthika. Gome logwirira ntchito limatenga mawonekedwe oponyera, ndipo pali T-slot yokhala ndi mawonekedwe omaliza pa ndege, yomwe imagwiritsidwa ntchito kukakamiza chogwirira ntchito. Dongosolo loyendetsa limatenga AC servo mota ndi kulondola kwa mpira screw pair kuyendetsa mbali zonse kuti gantry isunthire mbali ya X-axis. Maboti osinthika amagawidwa pansi pa bedi, omwe amatha kusintha mosavuta mlingo wa tebulo logwirira ntchito la bedi.

2. Gantry yamtundu wa mafoni:

Gantry yosunthika imaponyedwa ndikukonzedwa ndi chitsulo chotuwira (HT250), ndipo maupangiri oyenda omwe ali ndi mphamvu zambiri amayikidwa kutsogolo kwa gantry. Mpira wolondola kwambiri wowirikiza ndi injini ya servo imapangitsa kuti mutu wamagetsi usunthike molunjika ku Y-axis, ndipo mutu wakubowola umayikidwa pa slide yamphamvu. Kuyenda kwa gantry kumazindikirika ndi kuzungulira kwa wononga mpira moyendetsedwa ndi servo motor kudzera pakulumikizana kolondola.

3. Chishalo chotsetsereka:

Chishalo chotsetsereka ndi chitsulo chopangidwa mwaluso. Chishalo chotsetsereka chimakhala ndi masilayidi awiri otsogola okwera kwambiri a CNC, seti ya ma slide olondola kwambiri komanso chochepetsera chapamwamba kwambiri cha mapulaneti cholumikizidwa ndi injini ya servo kuyendetsa mutu wakubowola Kusuntha mbali ya Z-axis. amatha kuzindikira mutu wamphamvu kupita patsogolo, kupita patsogolo, kubwereranso, kuyimitsa ndi zina. Ili ndi ntchito za automatic chip breaking, kuchotsa chip ndi kuyimitsa.

4. Kubowola mphamvu mutu

Mutu wakubowola umatenga injini yodzipatulira ya servo spindle, yomwe imayendetsedwa ndi lamba wolumikizana ndi mano kuti awonjezere torque kuti ayendetse spindle yodzipatulira. Spindle imatengera kutsogolo zinayi ndi kumbuyo mizere iwiri isanu ndi umodzi yamakona aku Japan kuti ikwaniritse kusintha kosasintha. Spindle ili ndi makina osinthira zida za pneumatic kupanga chida Chosinthiracho chimakhala chofulumira komanso chosavuta, ndipo chakudya chimayendetsedwa ndi servo motor ndi screw ya mpira. Ma axes a X, Y, ndi Z amatha kulumikizidwa ndikutengera kuwongolera kotsekeka kotsekeka kuti akwaniritse ntchito zomasulira zozungulira komanso zozungulira.

BoolaMakina mwayi

1. Madzi kuchokera mu spindle:

Imatengera spindle yamadzi yaku Taiwan ya Jianchun ndi injini yamphamvu kwambiri ya servo spindle kuti iwongolere spindle kudzera pakuwongolera lamba kuti iwonjezere torque. Atha kugwiritsa ntchito drill yothamanga kwambiri ya U (bowola mwachiwawa) komanso pobowola pakati pamadzi.

2. Clamper

Ma axes a X ndi Y ali ndi zida zogwira ntchito kwambiri zomwe zimagwiritsidwa ntchito molumikizana ndi clamper ndi mzere wowongolera. Pogwiritsa ntchito mfundo za wedge blocks, ili ndi ntchito yokonza gantry, kuyika bwino, kuteteza kugwedezeka ndikuwongolera kukhazikika. Kapangidwe kake ndi kophatikizana komanso kamphamvu.

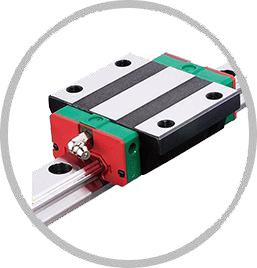

3. Liniya kalozera ndi mpira wononga

Imatengera njanji yaku Taiwan ya Shangyin yowongolera mzere ndi zomangira za mpira wamtundu wa TBI. Njanji zowongolera mbali zonse za bedi la makina zimayikidwa molunjika komanso mofananira, ndipo mphamvuyo imakhala yofanana, kuonetsetsa kuti makinawo akukhazikika komanso kuthamanga kwa makinawo.

4. Mphamvu mutu bwino yamphamvu

Pali ma silinda awiri pamwamba pa mutu wa mphamvu kuti muyese kulemera kwa mutu wa makina. Panthawi yokonza, mutu wa makinawo umakhala wokhazikika, kusalala kwa dzenje kumapangidwa bwino, ndipo kuvala pazitsulo za Z-axis kumachepetsedwa.

5. Chip kuchotsa dongosolo

Kumbuyo kwa chida cha makinawo pali cholumikizira mbale chachitsulo. Gwiritsani ntchito mfuti yamadzi yothamanga kwambiri kuti muthamangitse zitsulo mu chotengera chachitsulo, chomwe chimatumiza zitsulo, kupulumutsa nthawi yoyeretsa zitsulo ndi kuchepetsa ntchito. Chip conveyor ili ndi nyali yamadzi yamadzimadzi, yomwe imadzidzimutsa ngati madzi odulirawo sakukwanira.

Malangizo achitsanzo

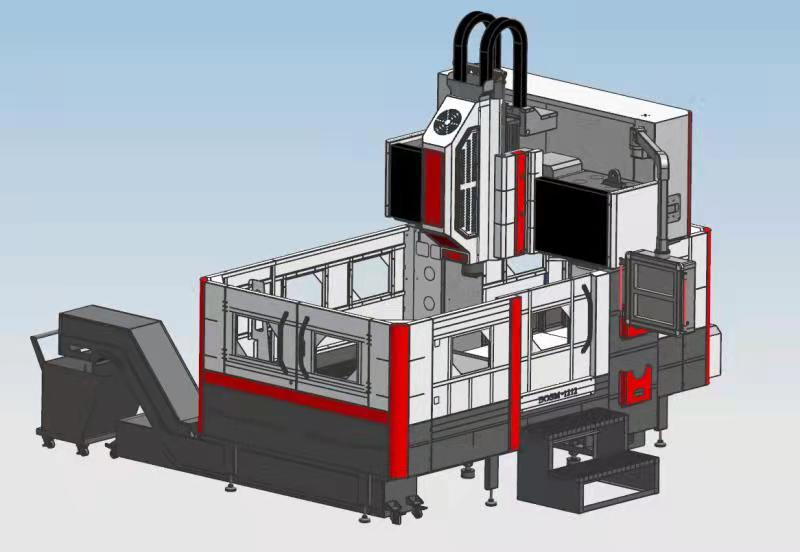

BOSM1600 * 1600 Self-centering CNC pobowola ndi mphero makina

BOSM1600 * 1600 mtundu mkulu-liwirogantry CNC kubowola ndi mpheromakinaili ndi sitiroko yogwira ntchito ya 1600 * 1600, yomwe ndi zida zotsika mtengo. Makinawa ali ndi nsagwada zinayi zodzipangira zokha, zomwe zimapangitsa kuti zikhale zosavuta komanso zofulumira kuwongolera zida za mphete. Kubowola kwakukulu ndi 50, Itha kugwiritsa ntchito pobowola madzi othamanga kwambiri mkati, ndege zamphero, milling grooves, ndi kukonza kwina. Zida zitha kukhala ndi magazini ya chida kuti ikwaniritse njira zingapo pakubowoleza kumodzi.

BOSM2500 * 2500 Self-centering CNC pobowola ndi mphero makina

BOSM-2525 Mtundu wa gantry wogawanika wathunthuMtengo wapatali wa magawo CNCmakina kubowola mndandanda zimagwiritsa ntchito pobowola mkulu-mwachangu wa mbale zazikulu, mbali mphepo mphamvu structural, zimbale, uinjiniya mbali makina structural, mavavu, mapepala chubu ndi workpieces ena mkati osiyanasiyana ogwira. Kugaya. Kubowola m'mabowo ndi mabowo akhungu kumatha kuzindikirika pazigawo zakuthupi limodzi ndi zida zophatikizika. Makina opangira makina amawongoleredwa ndi digito, ndipo ntchitoyo ndi yabwino kwambiri. Kuphatikiza pa zitsanzo zodziwika bwino, zimatha kupangidwanso ndikusinthidwa malinga ndi zosowa zenizeni za ogwiritsa ntchito.

CNC pobowola makina basipanopa chimagwiritsidwa ntchito mu makampani valavu, makampani flange, kuphulika-umboni makampani magetsi, makampani mphepo mphamvu, mafakitale nsalu makina, zomangamanga makina makampani, Machining makampani, makampani magalimoto, etc.

Kwa makasitomala omwe akupanga zinthu zozungulira monga ma flanges, mphete, zothandizira zowotchera, mapepala a chubu, etc., m'mimba mwake ndi zosakwana 2.2m, mzere wozungulira uli mkati mwa 2m m'mimba mwake, ndipo pobowo ndi mkati mwa 50mm. Kupweteka kwa makasitomala amtundu uwu wazinthu kumakhala mu nthawi yochepetsera Kuposa nthawi yopangira, zipangizo zamakono zopangira, mongaCNC gantry mpherokapena kubowola kwa radial, gwiritsani ntchito clamp kuti mutseke zinthuzo mukatsitsa, kenako gwiritsani ntchito chofufumitsa m'mphepete kapena gwiritsani ntchito chida chaukadaulo kuyesa tebulo kuti mupeze malo, omwe amawononga nthawi komanso kuchita bwino.

Mtengo wa BOSMkubowolamakinaidapangidwa ndi tebulo lokhazikika komanso gantry yosuntha. Imatengera chodzipangira chokhachokha chodzipangira chokha cha nsagwada zinayi, chomwe chimathetsa vuto la nsagwada zazing'ono zama hydraulic kapena pneumatic pamsika. Zida zazikulu zogwirira ntchito zidzagunda nsagwada pamene mukukweza Pankhani ya kuwonongeka kwa chuck, benchi yogwirira ntchito imaperekedwa ndi chojambula chojambula chojambula, ndipo clamping imangokhazikika panthawi imodzi, yomwe imathetsa vuto la nthawi yowonongeka.

Nsagwada zinayi pa benchi yogwirira ntchito zimatenga kalembedwe kake. Pambuyo disassembly, workbench akadali ochiritsira nsanja ndi T-mipata, amene bwino ntchito zosiyanasiyana machining workpieces ena kunja bwalo. Mtengo wa BOSMkubowola CNC makinaili ndi chowongolera njanji yowongolera, masekondi 0.06 othamanga kwambiri ndikutseka nthawi yoyankha, zomwe zimawongolera kulondola kwa makina ndi mphamvu yokhomerera, ndikuthetsa vuto lakale la kugwedezeka kwa spindle ndi moyo wa zida. Z-axis ziwiri zolimbitsa thupi, kukoka mafuta ndi gasi olekanitsidwa ndi magetsi, mawonekedwe okhazikika komanso olimba, mtengo wa kabati yamagetsi uli kumbuyo kuti uzitha kuyenda mosavuta, kalembedwe ka boom system ndikosavuta kugwiritsa ntchito, mabawuti a nangula atha kugwiritsidwa ntchito atakatera ndikuwongolera.

Mtengo wa BOSMmakina kubowola basi yakweza ndikukweza gawo lamutu la mtengo wazanja. Mzerewu ukasinthidwa, chitsulo chopanda madzi chimakhala bwino kwambiri, chopanda madzi chimakhala chabwino kwambiri, ndipo mawonekedwe ake amatha kukongola kwambiri.

Mtengo wa BOSM cnc pobowola makina kupangaili ndi makina opangira madzi apakati, ndipo kuthamanga kwa madzi kumakhala kwakukulu. Kapangidwe ka makina odulira kumbuyo kwachitsanzo ichi sikophweka kuyeretsa chitsulo chodula kutsogolo. Ili ndi mfuti yamadzi yochapira galimoto kutsuka chitsulo chakumbuyo.

Makampani opanga ma valve

Makampani a Flange

Makampani opanga magetsi osaphulika

Makampani opanga mphamvu zamagetsi

Makampani opanga makina opangira nsalu

Makampani opanga makina

Makampani omanga makina

Makampani opanga magalimoto

Fakitale ya BOSM ikupitirizabe kugwirizanitsa msika ndikupanga zitsanzo zatsopano kuti zichepetse ndalama zopangira ndi kupanga. Ili ndi ntchito zambiri zogwirira ntchito, kuphatikiza ndi zinachitikira pobowola, ndi ntchito wokometsedwa mphero. Mwachitsanzo, mtengo wokhazikika wa BOSM-DPH1212gantry mpherotapanga ndi kupanga pakali pano. Kwa iwo amene akufunika kubowola ndi mphero ndi m'lifupi processing wa 1200mm kapena kuchepera, ndi gantry ndalama.kubowola ndi mphero makinazomwe sizingasinthidwe kupitirira m'lifupi mwa malo opangira makina a VMC850 pamsika zitha kuzindikira makina opangira mphero. Zitsanzo malinga ndi ndondomeko.

Mtundu wa BOSM-DPH1212 umatha kuzindikira kukweza ndi mayendedwe, m'lifupi mwake chitha kukwezedwa mu chidebe, ndipo chitha kukhazikitsidwa mwachangu ndikugwiritsidwa ntchito pamalo a kasitomala. Kutanthauzidwa ngati kubowola mozungulira ndimphero makinachitsanzo chapakati, m'pofunika kuonetsetsa kulondola ndi kusasunthika kwa chida cha makina. Kalozera wa ma axis atatu adzagwiritsa ntchito maupangiri amtundu waku Taiwan, zomangira, ndi zomangira zogwirira ntchito pomaliza makina kuti zitsimikizire kuti zida zamakina zikuyenda bwino.

BOSM-DPH1212 fixed mtengo gantry mphero amayesetsa msika kumene m'lifupi la Machining Center sangathe kuthetsedwa, ndi mankhwala processing ndi zowononga ndi lalikulu gantry mphero. Mwachitsanzo, 1 mCNC gantry Machining Centerpa msika, ife kulunjika ambiri aCNC kubowola, mphesa, ndi wotopetsa. Kufunika kwa msika wamakina, palinso msika womwe umathetsa vuto la makina osokera amtundu wa nkhungu ndi mphero zama electromechanical spindles.

Nthawi yotumiza: Sep-20-2021