Gantry Type CNC Drilling And Milling Machine

CNC Gantry Milling And Drilling Machine

Gantry Drilling And Milling Machine

CNC Gantry Milling Machine

Kugwiritsa Ntchito Makina

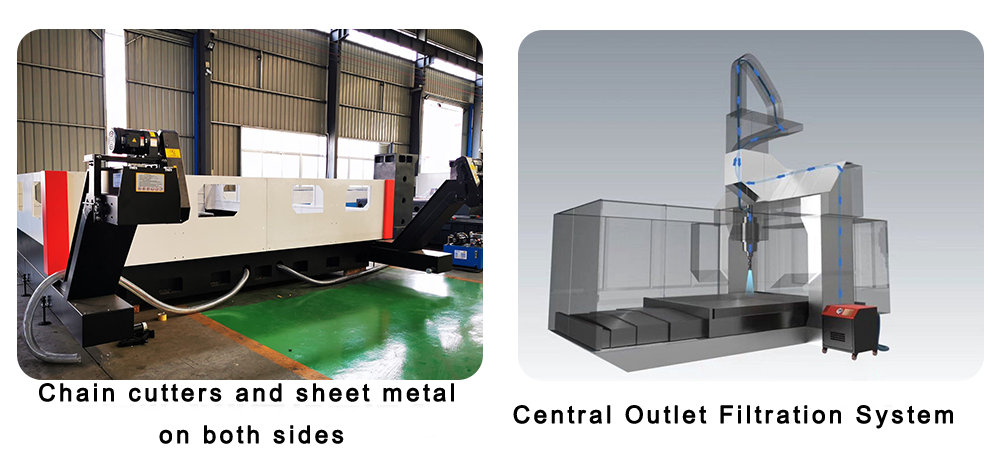

BOSM gantry mobile CNC mkulu-liwiro pobowola ndi mphero mndandanda makina zimagwiritsa ntchito kwambiri bwino pobowola ndi kukonza mbale zazikulu, mphepo flanges mphamvu, zimbale, mbali mphete ndi workpieces ena ndi makulidwe mkati osiyanasiyana ogwira. Kubowola m'mabowo ndi mabowo akhungu kumatha kuzindikirika pazigawo zakuthupi limodzi ndi zida zophatikizika. Makina opangira makina amawongoleredwa ndi digito, ndipo ntchitoyo ndi yabwino kwambiri. Imatha kuzindikira makina, kulondola kwambiri, mitundu ingapo komanso kupanga zambiri. Pofuna kukwaniritsa zosowa za ogwiritsa ntchito osiyanasiyana, kampaniyo yapanga zinthu zosiyanasiyana zomalizidwa. Kuphatikiza pa zitsanzo zodziwika bwino, zimatha kupangidwanso ndikusinthidwa malinga ndi zosowa zenizeni za ogwiritsa ntchito.

Kapangidwe ka Makina

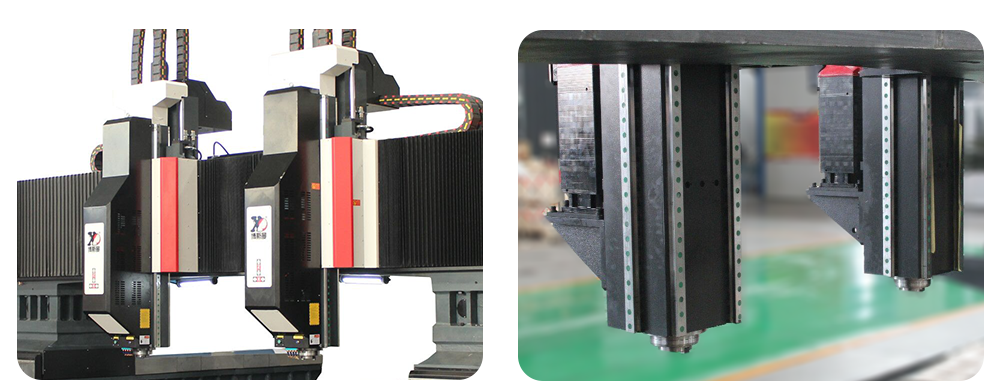

zida izi makamaka tichipeza worktable bedi, zosunthika gantry, zosunthika kutsetsereka chishalo, kubowola ndi mphero mphamvu mutu, basi kondomu chipangizo ndi chitetezo chipangizo, kuzungulira kuzirala chipangizo, dongosolo digito kulamulira, dongosolo magetsi, etc. Pereka kalozera njanji awiri thandizo ndi malangizo, mwatsatanetsatane lead screw pair drive, chida cha makina chimakhala ndi malo olondola kwambiri ndikubwereza kulondola kwa malo.

1)Ntchito:

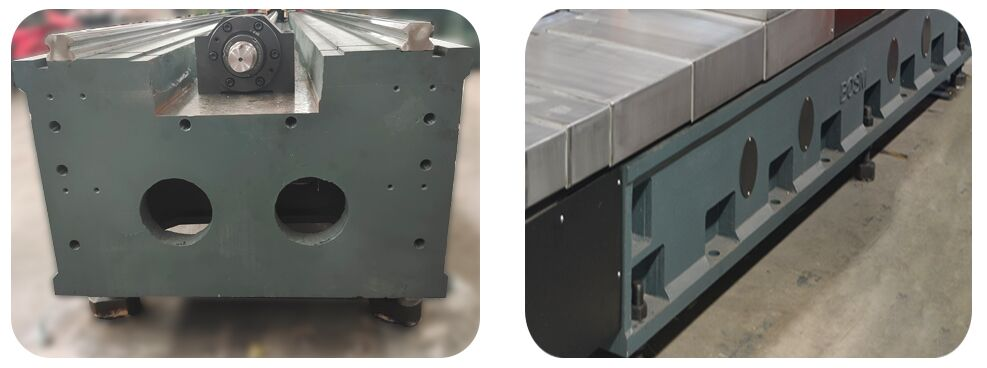

Bedi ndi gawo limodzi loponyedwa, lomalizidwa pambuyo pochiza kukalamba kwachiwiri komanso kugwedezeka, kukhazikika bwino komanso kusasunthika komanso kusasinthika. Pali ma T-slots okhala ndi kumalizidwa koyenera patebulo logwira ntchito kuti mugwire ntchito. Pansi pa bedi ili ndi maupangiri amtundu wa 2 olondola kwambiri (4 mbali zonse zonse), kotero kuti chowongolera chowongolera chimakhala chokhazikika, chomwe chimathandizira kwambiri kulimba kwa chida cha makina komanso kulimba kwake komanso kukanikiza. Dongosolo loyendetsa limatenga ma AC servo motors ndi ma peyala olondola a mpira. Side drive imapangitsa gantry kuyenda munjira ya X-axis. Maboti osinthika amagawidwa pansi pa bedi, omwe amatha kusintha mosavuta mlingo wa tebulo logwirira ntchito la bedi.

2)Movesigantry:

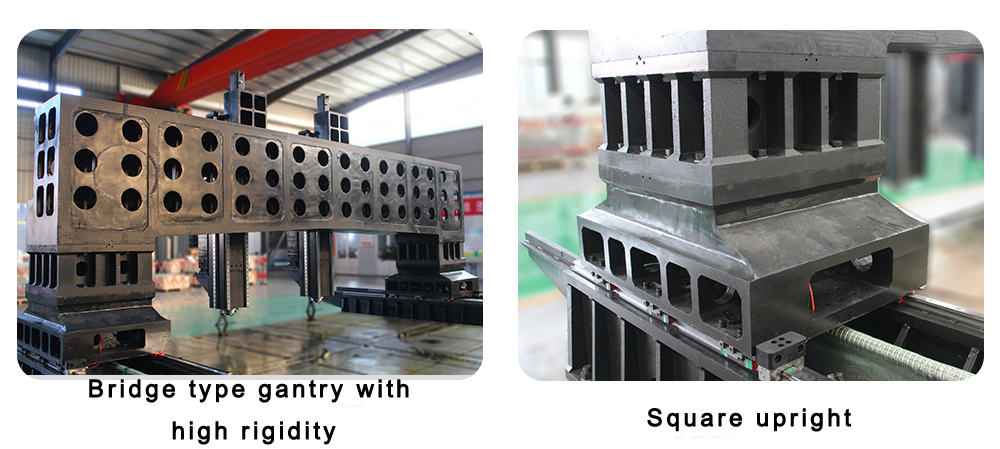

Gantry yosunthika imaponyedwa ndikukonzedwa ndi chitsulo chotuwira (HT250). Mawiri awiri a 55 # okwera kwambiri omwe amayendetsa mzere wowongolera amayikidwa kutsogolo kwa gantry. Seti yolondola ya mpira wononga awiri ndi injini ya servo imapangitsa kuti mutu wa mphamvu usunthike kuti usunthire mbali ya Y-axis, ndipo mutu wakubowola umayikidwa pamutu wamagetsi. Kuyenda kwa gantry kumazindikirika ndi kuzungulira kwa mpira wononga mtedza pa mpira wononga zoyendetsedwa ndi servo motor kudzera mwatsatanetsatane kugwirizana.

3)Movesisliding chishalo:

Chishalo chotsetsereka ndi chitsulo chopangidwa mwaluso. Chishalo chotsetsereka chimakhala ndi masilayidi a njanji okwera kwambiri a CNC, seti yowongoka bwino kwambiri komanso chochepetsera chapamwamba kwambiri cha mapulaneti cholumikizidwa ndi injini ya servo, yokhala ndi silinda ya nitrogen Balance, yoyezera kulemera kwa mutu wamagetsi, chepetsa katundu wa wononga zotsogola, onjezerani moyo wa screw screw, yendetsani mphamvu yakubowola kuti isunthire mbali ya Z-axis, ndikuzindikira kuthamangira, kuthamangira patsogolo, kubwereranso mwachangu, ndikuyimitsa zochita za mutu wamphamvu, wokhala ndi kuswa kwa Chip, kuchotsa chip, kuyimitsa ntchito.

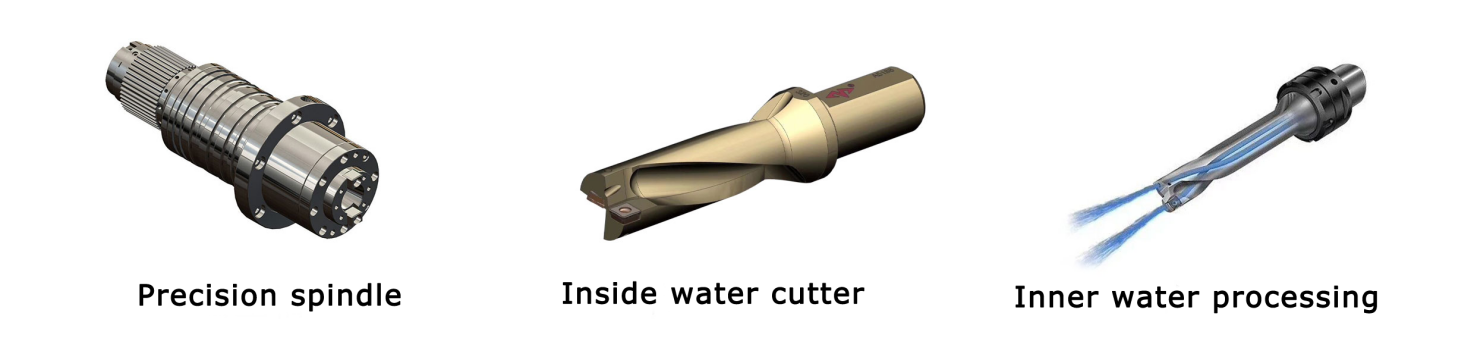

4)Kubowola mphamvu mutu(Spindle):

Mutu wamagetsi obowola umatenga injini yodzipatulira ya servo spindle, yomwe imayendetsedwa ndi lamba wa synchronous lamba kuti iwonjezere torque ndikuyendetsa spindle yodzipatulira. Spindle imatenga mizere inayi yoyambirira ndikumbuyo mizere iwiri isanu ndi umodzi ya ma bearing a ku Japan kuti ikwaniritse kusintha kosasintha. Spindle ili ndi makina osinthira zida za pneumatic kupanga chida Chosinthiracho chimakhala chofulumira komanso chosavuta, ndipo chakudya chimayendetsedwa ndi servo motor ndi screw ya mpira. Ma axes a X ndi Y amatha kulumikizidwa, pogwiritsa ntchito kuwongolera kozungulira kotsekeka, komwe kumatha kuzindikira ntchito zomasulira zozungulira komanso zozungulira. Mapeto a spindle ndi bowo la taper la BT50, lokhala ndi ma Rotofors aku Italy othamanga kwambiri, omwe amatha kukonzedwa ndi malo othamanga kwambiri a U-bowola.

4.1 Bokosi la bokosi ndi tebulo lotsetsereka la mutu wobowola amapangidwa ndi ma castings kuti apititse patsogolo kukhazikika kwawo komanso kukhazikika, ndikuchepetsa kugwedezeka ndi phokoso.

4.2 Chida cha makina amatha kuyendetsedwa ndi gudumu lamagetsi; kuti musunge nthawi ndikuwongolera kupanga bwino pakukonza, mutatha kubowola dzenje loyamba kukhazikitsa malo odyetserako chakudya, kubowola mabowo otsala amtundu womwewo kumatha kukwaniritsa mwachangu → kutsogola ntchito → kubwerera mwachangu Iyeneranso kukhala ndi ntchito monga chip chodziwikiratu. kuswa, kuchotsa chip, ndi kupuma.

4.3 Nkhosa yamphongoyo ili ndi makina amadzimadzi a nitrogen kuti achepetse katundu wa Z-axis ndikuwonjezera moyo wautumiki wa Z-axis screw.

4.4 Z-axis servo motor imatenga mphamvu yamagetsi yamagetsi, yomwe idzagwira brake pamene mphamvu imadulidwa mwadzidzidzi kuti ipewe ngozi zomwe zimachitika chifukwa cha kugwa kwa bokosi la spindle.

4.5 Mutu wamutu

4.5.1. Bokosi lalikulu la shaft limatenga maulozera anayi olemetsa, okhala ndi kusasunthika kwakukulu, kulondola kwa malo apamwamba, komanso kukhazikika kwa liwiro lotsika.

4.5.2. Z-axis drive-motor ya servo imalumikizidwa mwachindunji ndi wononga mpira polumikizana, ndipo zomangira za mpira zimayendetsa mutuwo kuti usunthe mmwamba ndi pansi pa chishalo kuti uzindikire chakudya cha Z-axis. Galimoto ya Z-axis ili ndi ntchito yoboola yokha. Kukanika mphamvu, shaft yamoto imagwiridwa mwamphamvu kuti isazungulire.

4.5.3. Gulu la spindle limagwiritsa ntchito spindle yamadzi ya Taiwan Jianchun yothamanga kwambiri, yomwe imakhala yolondola kwambiri komanso yogwira ntchito kwambiri. Tsinde lalikulu limagwira mpeni ndi kasupe wa gulugufe patsinde lalikulu ndi mphamvu yamphamvu yomwe ikugwira ntchito pa kukoka msomali wa chogwirira cha chida kudzera pamakina anayi a broach, ndipo chida chotayirira chimatenga njira ya pneumatic.

5)Chida chodzitchinjiriza chodzitchinjiriza ndi chipangizo choteteza:

Pali cholumikizira chip chodziwikiratu mbali zonse za benchi yogwirira ntchito ndi fyuluta kumapeto. The automatic chip conveyor ndi mtundu wathyathyathya. Mbali imodzi imakhala ndi mpope wozizirira, ndipo chotulukacho chimalumikizidwa ndi makina apakati amadzi ndi payipi. , Choziziriracho chimalowa mu chotengera cha chip, mpope wonyamulira chip umapopa choziziritsa kukhosi mu sefa yapakati, ndipo pampu yozizirira yothamanga kwambiri imazungulira choziziritsa chosefedwa mpaka pobowola spindle. Ilinso ndi trolley yonyamula chip, yomwe ndi yabwino kwambiri kunyamula tchipisi. Zidazi zili ndi zida zoziziritsa zamkati ndi zakunja. Kubowola kothamanga kwambiri kumagwiritsidwa ntchito, kuziziritsa kwamkati kwa chida kumagwiritsidwa ntchito, ndipo kuziziritsa kwakunja kumagwiritsidwa ntchito popera kuwala.

5.1. Dongosolo la kusefera kwamadzi lapakati:

Makinawa ali ndi makina apakati osefera madzi, omwe amatha kusefa bwino zonyansa muzoziziritsa kukhosi. Dongosolo lamkati lopopera madzi limatha kuletsa zikhomo zachitsulo kuti zisamangidwe pa chida pakukonza, kuchepetsa kuvala kwa zida, kukulitsa moyo wa zida, ndikuwongolera kumapeto kwa chogwiriracho. Pini yotulutsa madzi yothamanga kwambiri imatha kuteteza pamwamba pa chogwirira ntchito, kuteteza cholumikizira chothamanga kwambiri, kuteteza zonyansa kuti zisatseke cholumikizira chozungulira, ndikuwongolera magwiridwe antchito onse, ndikuwongolera magwiridwe antchito.

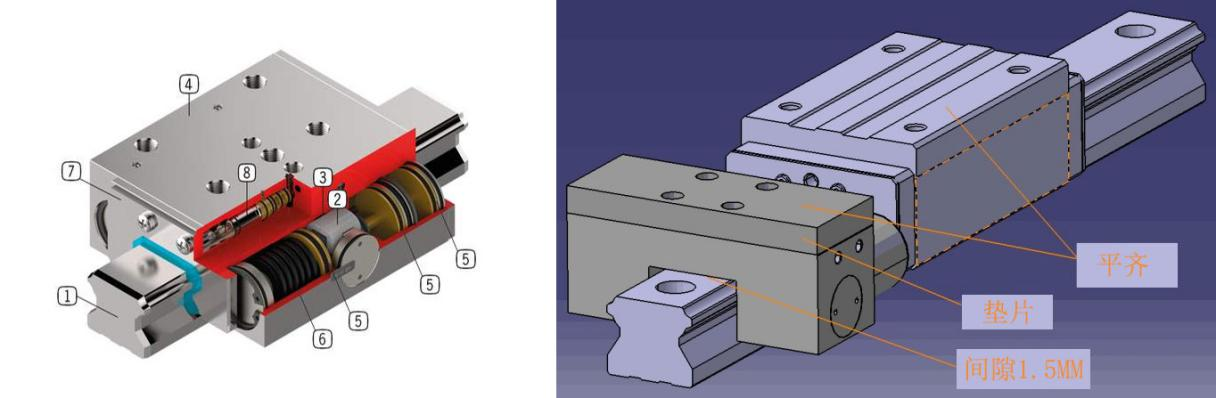

6)Linear Clamper:

Choyimitsacho chimapangidwa ndi thupi lalikulu la clamp, actuators, etc. Ndi gawo logwira ntchito kwambiri lomwe limagwiritsidwa ntchito molumikizana ndi gulu lowongolera lozungulira. Kupyolera mu mfundo ya kukulitsa mphamvu ya wedge block force, imapanga mphamvu yokhotakhota yamphamvu; ili ndi gantry yokhazikika, malo enieni, anti-vibration ndi Ntchito kuti ikhale yolimba.

Lili ndi izi:

Otetezeka komanso odalirika, mphamvu yokhotakhota yolimba, kukakamiza XY axis yosasuntha pobowola ndi kukonza.

Kuthamanga kwakukulu kwambiri kumawonjezera kulimba kwa chakudya cha axial ndikuletsa kukhumudwa komwe kumachitika chifukwa cha kugwedezeka.

Kuyankha mwachangu, nthawi yotsegulira ndi kutseka yoyankha ndi masekondi 0.06 okha, omwe angateteze chida cha makina ndikuwonjezera moyo wa screw screw.

Chokhazikika, chokutidwa ndi faifi tambala, ntchito yabwino yolimbana ndi dzimbiri.

Kupanga kwatsopano kuti mupewe zovuta mukamangirira.

7)Position ndi clamping wa workpiece

Pamalumikizidwe ozungulira a flange, amatha kuyikidwa mosasamala pa mbale yothandizira ndi T-mipata, ndipo malo apakati amayezedwa ndi chopeza m'mphepete chomwe chimayikidwa mu dzenje la spindle pa mfundo zitatu zilizonse (m'mimba mwake wamkati kapena m'mimba mwake) pa workpiece. . Kenako, izo basi analandira ndi manambala ulamuliro pulogalamu mawerengedwe, amene ali molondola ndi mofulumira. The clamping ya workpiece ndi clamped ndi chomangira wopangidwa ndi mbale kukanikiza, ndodo ejector, tayi ndodo ndi khushoni chipika, amene ndi yabwino ntchito.

8)Makina opangira mafuta

Chida cha makina ichi chili ndi chipangizo choyambirira cha Taiwan cha volumetric partial pressure automatic automatic, chomwe chimatha kudzipangira mafuta awiriawiri osiyanasiyana monga njanji zowongolera, zomangira zowongolera, zomangira, ndi zina zambiri, popanda nsonga zakufa, ndikuwonetsetsa moyo wautumiki wa chida cha makina. Njanji zowongolera mbali zonse za bedi la makina zimakhala ndi zotchingira zosapanga dzimbiri zoteteza, ndipo mbali zonse ziwiri za mutu wamagetsi osunthika zili ndi zotchingira zosinthika. Malonda otchinga madzi amaikidwa mozungulira pogwiritsira ntchito, ndipo mzere wa mapaipi amadzi umatetezedwa ndi unyolo wa pulasitiki. Chophimba chofewa chowoneka bwino cha PVC chimayikidwa mozungulira pozungulira.

9)Wowongolera wa digito wa CNC:

9.1. Ndi chip breaking function, chip breaking time and chip breaking cycle zitha kukhazikitsidwa pamakina amunthu.

9.2. Ndi ntchito yokweza chida, kutalika kwa chida kumatha kukhazikitsidwa pamawonekedwe a makina amunthu. Pobowola mpaka kutalika uku, kubowolako kumakwezedwa mwachangu pamwamba pa workpiece, ndiyeno kumeta, kenako kuthamangira pobowola pamwamba ndikusinthidwa kukhala chakudya chantchito.

9.3. Bokosi lapakati loyang'anira ntchito ndi gawo logwirizira m'manja limatenga makina owongolera manambala, ndipo lili ndi mawonekedwe a USB ndi chiwonetsero cha LCD chamadzimadzi. Pofuna kuwongolera mapulogalamu, kusungirako, kuwonetsera ndi kulankhulana, mawonekedwe ogwiritsira ntchito ali ndi ntchito monga kukambirana ndi makina a munthu, kubwezera zolakwika, ndi alamu yokha.

9.4. Zipangizozi zimakhala ndi ntchito yowonetseratu ndikuwunikanso malo a dzenje musanayambe kukonza, zomwe zimakhala zosavuta kugwira ntchito.

10)Optical Edge Finder:

Zipangizozi zimakhala ndi chithunzithunzi cha m'mphepete mwa photoelectric, chomwe chimatha kupeza malo a workpiece mosavuta komanso mofulumira.

1) Ikani chofufutira m'mphepete mwa spindle chuck ya chida cha makina, ndipo pang'onopang'ono mutembenuzire spindle kuti mukonze kukhazikika kwake.

2) Sunthani spindle ndi gudumu lamanja, kotero kuti m'mphepete mwa mpira wachitsulo wopeza m'mphepete umakhudza chogwirira ntchito mopepuka, ndipo kuwala kofiira kumayatsidwa. Panthawiyi, spindle ikhoza kusunthidwa kutsogolo ndi kumbuyo mobwerezabwereza kuti mupeze malo abwino kwambiri omwe m'mphepete mwa mpira wachitsulo wopeza m'mphepete umakhudza chogwirira ntchito. .

3) Lembani ma axis a X ndi Y omwe akuwonetsedwa ndi dongosolo la CNC panthawiyi, ndikudzaza kompyuta.

4) Pezani malo ozindikira angapo motere

11)Alamu yovala zida

Chida chovala alamu chimazindikira kwambiri momwe injini ya spindle ikuyendera. Zamakono zikadutsa mtengo wokonzedweratu, chipangizocho chimangoweruza kuti chidacho chatha, ndipo spindle idzachotsa chidacho panthawiyi, ndipo pulogalamu yokhayo idzatha. Kumbutsani wogwiritsa ntchitoyo kuti chida chatha.

12)Alamu yotsika yamadzi

1) Chozizirira mu fyuluta chikafika pakatikati, makinawo amalumikizana ndi mota kuti ayambike, ndipo choziziritsa kukhosi mu chotengera cha chip chimangolowa mu fyuluta. Ikafika pamtunda wapamwamba, injiniyo imasiya kugwira ntchito.

2) Choziziritsa mu fyuluta chikafika potsika, makinawo amangopangitsa kuti mulingowo ukhale alamu, spindle imangochotsa chidacho, ndipo makinawo amasiya kugwira ntchito.

13) Ntchito ya kukumbukira mphamvu

Chifukwa cha kuyimitsidwa kwa opareshoni chifukwa cha kulephera kwadzidzidzi kwamphamvu, ntchitoyi imatha kupeza mwachangu komanso mosavuta malo a dzenje lomaliza lomwe linabowoledwa mphamvu isanathe. Othandizira amatha kupita ku sitepe yotsatira, ndikusunga nthawi yosaka.

Kuyang'ana kwa laser-axis atatu:

Makina aliwonse a Bosman amayesedwa ndi laser interferometer ya kampani yaku Britain ya RENISHAW, ndikuwunika molondola ndikuwongolera zolakwika, kubweza, kulondola kwa malo, kubwereza kulondola kwa malo, etc. . Kuwunika kwa Ballbar Makina aliwonse amagwiritsa ntchito mpira waku Britain RENISHAW kutsimikizira kulondola kwa bwalo ndi makina olondola a geometric. Nthawi yomweyo, kuyesa kozungulira kozungulira kumachitika kuti zitsimikizire kulondola kwa makina a 3D ndi kulondola kwa bwalo.

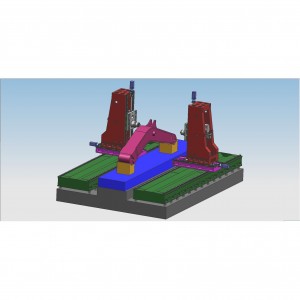

Masanjidwe a nsanja, clamping ya workpiece, zofunikira zochotsa chip zokha

1. Pulatifomu yaikulu (1 ma PC): T-slot clamping workpiece. Onse pamwamba mapeto pamwamba ndi mbali pamwamba pa nsanja yaikulu angagwiritsidwe ntchito ngati processing malo pamalo.

2. Sinking nsanja (1 ma PC): (mbali ali okonzeka ndi wothandiza atolankhani-woyenerera chimango, ndipo pamwamba okonzeka ndi zonse chophimba zoteteza chivundikirocho, anakonza ndi anaika ndi wogulitsa), waukulu workpiece udindo ndi malangizo processing:

Kukonzekera kwa chivundikiro cha mavavu: kuyikika kwa nsanja yotsika (chogwirira chapansi chothandizira ndi zogwirira ntchito zamitundu yosiyanasiyana), mbale yoponderezedwa yapamwamba imakhazikika ndikukankhira kapena wogulitsa akupanga cholumikizira chapamwamba chodziwikiratu.

Kukonza thupi la mavavu: kuyikika kwa nsanja yotsika (zogwirizira zapansi ndi zogwirira ntchito zamitundu yosiyanasiyana), zogwirira zam'mbali za gawo lothandizira la nsanja yapansi ndi ndodo za ejector zooneka ngati L zimakanikizidwa ndikukhazikika kapena wogulitsa amapanga chowonjezera chodziwikiratu. clamping chipangizo.

Kufotokozera

| Chitsanzo | Chithunzi cha BOSM-DS3030 | Chithunzi cha BOSM-DS4040 | Chithunzi cha BOSM-DS5050 | Chithunzi cha BOSM-DS6060 | |

| Kugwira Ntchito | kutalika* m'lifupi | 3000*3000 | 4000 * 4000 | 5000 * 5000 | 6000*6000 |

| Mutu Wobowola Woima | Spindle taper | Mtengo wa BT50 | |||

| Kubowola Diameter (mm) | φ96 | ||||

| Kugunda Diameter(mm) | M36 | ||||

| Liwiro la Spindle (r/min) | 30 ~ 3000/60 ~ 6000 | ||||

| Spindle Motor Power (kw) | 22/30/37 | ||||

| Spindle Mphuno Kuti Table Distance | Malinga ndi maziko | ||||

| Bweretsani Kulondola Kwamayimidwe (X/Y/Z) | X/Y/Z | ± 0.01/1000mm | |||

| Control System | KND/GSK/SIEMENS | ||||

| Chida cha Magazini | Chida chamagazini cha Okada chokhala ndi zida 24 ngati mukufuna | ||||

Kuyang'anira Ubwino

Makina aliwonse a Bosman amayesedwa ndi laser interferometer yochokera ku kampani ya United Kingdom RENISHAW, yomwe imayang'ana molondola ndikubwezera zolakwika za phula, kubweza, kulondola kwa malo, komanso kukhazikika kobwerezabwereza kuwonetsetsa kuti makinawo ndi amphamvu, osasunthika komanso olondola. . Mpira bala mayeso Makina aliwonse amagwiritsa ntchito choyesera mpira kuchokera ku kampani yaku Britain ya RENISHAW kukonza kulondola kwa bwalo lolondola ndi makina olondola a geometric, ndikuchita zoyeserera zodulira zozungulira nthawi imodzi kuti zitsimikizire kulondola kwa makina a 3D ndi kulondola kwa bwalo.

Malo ogwiritsira ntchito chida cha makina

1.1 Zida zofunikira zachilengedwe

Kusunga mulingo wokhazikika wa kutentha kozungulira ndikofunikira kwambiri pakukonza makina.

(1) Kutentha komwe kulipo ndi -10 ℃ ~ 35 ℃. Kutentha kozungulira 20 ℃, chinyezi chiyenera kukhala 40 ~ 75%.

(2) Pofuna kusunga kulondola kwachida cha makina mkati mwazomwe zatchulidwa, kutentha kwabwino kwambiri kumafunika kukhala 15 ° C mpaka 25 ° C ndi kusiyana kwa kutentha.

Siyenera kupitirira ± 2 ℃ / 24h.

1.2 Mphamvu yamagetsi: 3-gawo, 380V, kusinthasintha kwamagetsi mkati mwa ± 10%, ma frequency amagetsi: 50HZ.

1.3 Ngati voteji pamalo ogwiritsira ntchito ndi osakhazikika, chida cha makina chiyenera kukhala ndi magetsi oyendetsedwa bwino kuti atsimikizire kuti makinawo akugwira ntchito bwino.

1.4. Chida cha makina chiyenera kukhala ndi maziko odalirika: waya woyakirapo ndi waya wamkuwa, waya wosachepera 10mm², ndipo kukana kwapansi kumakhala kosakwana 4 ohms.

1.5 Kuti zitsimikizire kuti zida zogwirira ntchito zikuyenda bwino, ngati mpweya woponderezedwa wa gwero la mpweya ukulephera kukwaniritsa zofunikira za gwero la mpweya, zida zoyeretsera mpweya (dehumidification, degreasing, kusefa) ziyenera kuwonjezeredwa pamaso pa mpweya wa makina.

1.6. Zidazi ziyenera kusungidwa kutali ndi kuwala kwa dzuwa, kugwedezeka ndi kutentha, komanso kutali ndi majenereta othamanga kwambiri, makina opangira magetsi, ndi zina zotero, kuti apewe kulephera kupanga makina kapena kutaya makina olondola.

Pamaso & Pambuyo Service

1) Pamaso pa Service

Kupyolera mu phunziro pempho ndi mfundo zofunika kwa makasitomala ndiye ndemanga kwa akatswiri athu, Bossman Technical gulu ndi udindo kulankhulana luso ndi makasitomala ndi mapangidwe mayankho, kuthandiza kasitomala kusankha njira yoyenera Machining ndi makina oyenera.

2) Pambuyo pa Service

A.Makina omwe ali ndi chitsimikizo cha chaka chimodzi ndikulipirira kukonza kwa moyo wonse.

B.Panthawi yachitsimikizo cha chaka chimodzi makinawo atafika padoko, BOSSMAN idzapereka chithandizo chaulere komanso chanthawi yake pazolakwa zosiyanasiyana zomwe sizinapangidwe ndi anthu pamakina, ndikusintha munthawi yake mitundu yonse ya zida zowonongeka zomwe sizinapangidwe ndi anthu. cha malipiro . Zolephera zomwe zimachitika panthawi ya chitsimikizo zidzakonzedwa pamitengo yoyenera.

Thandizo la C.Technical mu maola 24 pa intaneti, TM, Skype, E-mail, kuthetsa mafunso achibale mu nthawi. ngati sizingathetsedwe, BOSSMAN ikonza nthawi yomweyo kuti mainjiniya atagulitsa azifika pamalowo kuti akonzedwe, wogula amayenera kulipira VISA, matikiti oyendetsa ndege ndi malo ogona.

Tsamba la Makasitomala