E30 CNC Cylindrical Akupera Makina Kwa Zida Zodula

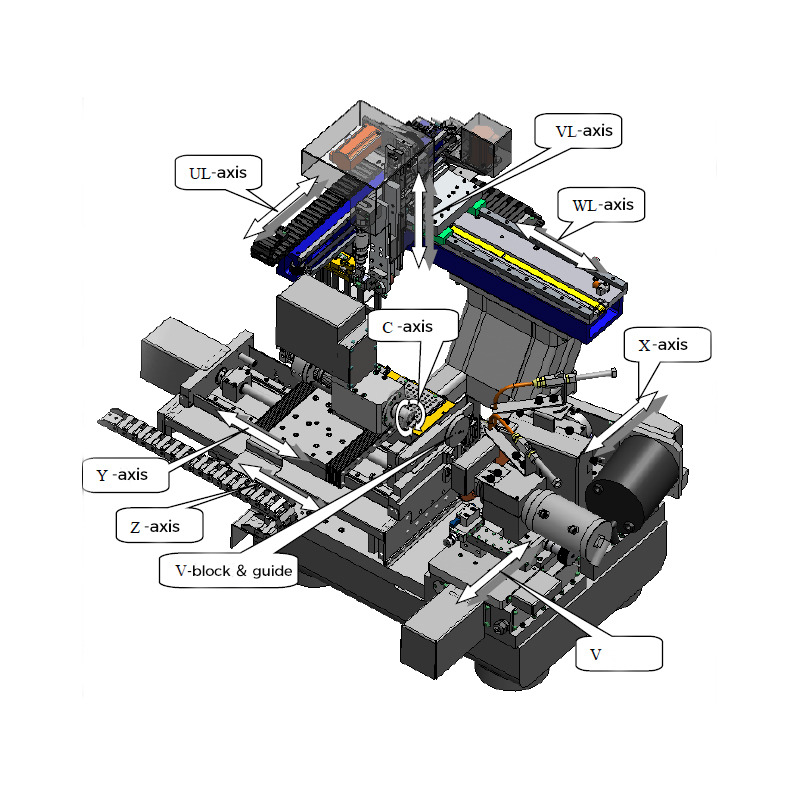

Main kapangidwe chithunzi cha makina

Kuchuluka kwa ntchito

Ntchito zosiyanasiyana: chodula mphero, kubowola pang'ono, reamer ndi magawo osiyanasiyana olondola kwambiri.

Processing osiyanasiyana: awiri osiyanasiyana kukonzedwa: Φ3~Φ20mm, kutalika kwa mankhwala kukonzedwa: 120mm (zokha), 330mm (pamanja).

Processing makhalidwe: munthawi yomweyo akupera zabwino ndi coarse awiri akupera mawilo, nthawi imodzi processing ndi kupanga.

Makina oyamba

1. Mapangidwe a bedi:

2. Chitsulo chachitsulo cha makina onse: makina onse ali ndi mawonekedwe otsekedwa, ndipo chimango chachikulu chimasiyanitsidwa ndi chivundikiro chakunja kuti chiteteze kugwedezeka.

3. Dongosolo lowongolera: NEWCON

4. Mfundo yochepetsera:

• X-axis (mawilo okulirapo): zindikirani kusuntha kwa magudumu okulirapo munjira ya X-axis;

• V-axis (makina opangira ma gudumu abwino): zindikirani kusuntha kobwerezabwereza kwa gudumu lopukutira munjira ya V-axis;

• Y-axis (Y-axis feed mechanism): zindikirani kusuntha kobwerezabwereza kwa tebulo logwirira ntchito munjira ya Y-axis;

• C axis (machitidwe ozungulira mutu): zindikirani kusuntha kwa mutu wogwira ntchito molunjika ku C axis :;

• UL axis, VL axis ndi WL axis (mamanipulator pick-and-place mechanism): zindikirani kusuntha kobwerezabwereza kwa chowongolera munjira yopingasa ndi yoyima;

• Thandizo la gudumu ndi V-block: Zothandizira pakumaliza kukonza.

1. Zigawo zosuntha: X axis, V axis, Y axis, WL axis, UL axis, VL axis, wheel wheel, makina a mkono, hysteresis adjustment mechanism

2. Spindle yopangira: Chuangyun wodzipangira yekha

3. Kupeta spindle: Xiamen Tungsten Motor

4. Kupaka mafuta pamakina onse: nsonga zamafuta zimasungidwa pa axis iliyonse ndikuthiridwa mafuta pafupipafupi.

5. Kudyetsa njira: atatu olamulira manipulator kudyetsa

Mfundo zaukadaulo

| njira yolamulira | Makatani akunja, skrini yogwira | |

| Njira yowonetsera | Chophimba chokhudza, kuwala kochenjeza | |

| njira yozizira | Mafuta ozizira | |

| njira yotumizira | Hydraulic, pneumatic, servo motor | |

| magetsi | AC 3 × 380V, 50Hz | |

| Zolemba zonse mphamvu | 25KW | |

| Makulidwe | 2152 × 1838 × 2614 mm | |

| malemeledwe onse | 3050kg | |

| Kuzizira kwamafuta amafuta | 0.6-0.8MPa | |

| kuthamanga kwa barometric | Kuthamanga konse kwa msewu: 5 ~ 6Bar | |

| Kuthamanga kwa mpweya wa Chuck: 2 ~ 3Bar | ||

| Kuthamanga kwa mpweya wowongolera: 2 ~ 2.5Bar | ||

| Kuthamanga kwa mpweya wa Gripper: 1.5 ~ 4Bar | ||

| Kuthamanga kwa mpweya wa mkono: 5 ~ 6Bar | ||

| Kuthamanga kwa mpweya kwa kuwala kwa kuwala: 0.6 ~ 0.7Bar | ||

| Manipulator magawo | ||

| UL axis | Maulendo | 450 mm |

| Kubwerezabwereza | 0.02 mm | |

| Kuthamanga kwakukulu kwa ntchito | 15000mm / mphindi | |

| Mtundu wa VL | Maulendo | 100 mm |

| Kubwerezabwereza | 0.02 mm | |

| Kuthamanga kwakukulu kwa ntchito | 15000mm / mphindi | |

| WL axis | Maulendo | 540 mm |

| Kubwerezabwereza | 0.02 mm | |

| Kuthamanga kwakukulu kwa ntchito | 15000mm / mphindi | |

| Processing axis parameter | ||

| Y axis | Maulendo | 350 mm |

| Kulondola Kochepa Kwambiri | 0.0001mm | |

| X axis | Maulendo | 35 mm |

| Kulondola Kochepa Kwambiri | 0.0001mm | |

| V axis | Maulendo | 35 mm |

| Kulondola Kochepa Kwambiri | 0.0001mm | |

| Gudumu lotsogolera | Kulondola kozungulira: | ≤0.010mm |

| Mutu wogwira ntchito (C axis) | Mphamvu Yamagetsi | 1.57kw |

| Liwiro lozungulira | ≤2000rpm | |

| Kulondola kothamanga | ≤0.002mm | |

| kusamvana kochepa | 0.0001 ° | |

| Woukali akupera gudumu spindle | Mphamvu Yamagetsi | 8.5KW |

| Liwiro lozungulira | ≤5000rpm | |

| Kulondola kothamanga | ≤0.002mm | |

| dynamic balance | ≤G0.4 | |

| Chophimba bwino cha gudumu lopukuta | Mphamvu Yamagetsi | 1.4KW |

| Liwiro lozungulira | ≤7950rpm | |

| Kulondola kothamanga | ≤0.002mm | |

| dynamic balance | ≤G0.4 | |

| Akupera magawo |

|

|

| Chuck model | W20 | |

| M'mimba mwake mwa gudumu lopera | Ø 250 mm | |

| Fine akupera gudumu diameter | Ø 150 mm | |

| Workpiece Shank Diameter | Ø3-Ø12mm (zokha) / Ø3-Ø20mm (pamanja) | |

| Ntchito Yogaya Range | Ø0.08 - Ø20mm | |

| kutalika kwa workpiece | 120mm (zokha) / 350mm (pamanja) | |

| The pazipita processing kutalika kwa workpiece | 330 mm | |

| Processing akunja m'mimba mwake | ≤0.003mm | |

| Kutalika kwa makina olondola | ± 0.1mm | |

| Kulondola kwa makina a angle | ≤0.3° | |

| Mawonekedwe olondola | ≤Ra0.4 (kumaliza kugaya) | |

Standard kasinthidwe mndandanda

| 10 | CNC ndondomeko | NEWC0N | 1 |

| 20 | injini ya servo | NEWC0N | 8 |

| 30 | Woyendetsa seva | NEWC0N | 4 |

| 40 | Operation panel / gudumu lamanja | NEWC0N | 1 |

| 50 | High mwatsatanetsatane mutu mutu module | Zotsatira GESAC | 1 |

| 60 | Spindle yamagetsi yolondola kwambiri (1.4KW) | Zotsatira GESAC | 1 |

| 70 | Motor yolondola kwambiri (7.1KW) | Zotsatira GESAC | 1 |

| 80 | High Precision Mechanical Spindle | Zotsatira GESAC | 1 |

| 90 | Sitima yolondola | Schneeberger | 10 |

| 100 | Precision Crossed Roller Linear Way | Schneeberger | 4 |

| 110 | Precision Ball Screw | NSK | 4 |

| 120 | Ntchito ndi kukonza kayeseleledwe mapulogalamu (standard sitepe kusiyana, spherical, etc.) | Zotsatira GESAC | 1 |

| 130 | Inverter | Zotsatira GESAC | 1 |

| 140 | Inverter | Zotsatira GESAC | 1 |

| 150 | zenera logwira | 19 ELO | 1 |

| 160 | Chida chachitetezo chachitetezo cha makina otseka chitseko | Jinzhong | 1 |

| 170 | sensa | Baumer | 3 |

| 180 | sensa yotuluka | Yifumeni | 1 |

| 190 | Zida zamagetsi | Schneider | 1 |

| 200 | Pneumatic Components | CKD | 1 |

| 210 | Waya ndi Chingwe | ComCab | 1 |

| 220 | Choyatsira air conditioner | Zotsatira GESAC | 1 |

| 230 | Kuthamanga kwachangu gudumu Ø92x8 | Zotsatira GESAC | 1 |

| 240 | Kuthamanga kwachangu gudumu Ø92x15 | Zotsatira GESAC | 1 |

| 250 | Chuck W20 D4 | Zotsatira GESAC | 1 |

| 260 | Tray yokhazikika D4 | Zotsatira GESAC | 3 |

| 260 | Kufananiza kwambiri V-block (3-6) * 10 | Zotsatira GESAC | 1 |

| 280 | Mkulu mwatsatanetsatane akupera gudumu flange (mwachangu kusintha mtundu) | Zotsatira GESAC | 2 |

| 290 | Zala zonse za manipulator | Zotsatira GESAC | 1 |

Makhalidwe a makina

Nkhwangwa za 7 CNC, nkhwangwa 4 za CNC zimagwiritsidwa ntchito m'malo opangira zinthu, zomwe zimatha kuzindikira kutsitsa ndikutsitsa, kupanga batch popanda munthu.

Kulondola kwa Machining ndi luso la zida zamakina

1. Kuthamanga kwa radial kwa workpiece kuli mkati mwa 0.003mm;

2. Kulondola kwa kukula kwa 2.0 kumayendetsedwa mkati mwa ± 0.005mm;

3. Kuzungulira kwa workpiece kuli mkati mwa 0.003mm;

4. Kukula kwapamtunda <Ra0.4;