Mindandanda ya CBS yokhala ndi ma axis vertical vertical Machining Center

Mawonekedwe

1.Main magwiridwe antchito

1.1. X-axis imagwiritsa ntchito teknoloji yoyendetsa galimoto, Y-axis imagwiritsa ntchito teknoloji yofanana yoyendetsa galimoto ndi kuwongolera kofananira, ndi kuthamanga kwakukulu, phokoso lochepa, kuthamanga kwachangu, ndi ntchito yabwino kwambiri. Ma axis atatu a X/Y/Z onse amatenga mayankho olondola kwambiri amizeremizeremizere, ndi malo olondola kwambiri.

1.2.Moto wokwera kwambiri wa torque umayendetsa A-axis ndi C-axis kuti azizungulira, ndi zero transmission chain, zero backlash, ndi kukhazikika bwino; encoder yolondola kwambiri imakwaniritsa malo ake enieni

1.3.The spindle imatengera mawonekedwe othamanga amagetsi othamanga kwambiri ndi liwiro lalikulu komanso phokoso lochepa.

2.Mapangidwe apamwamba a mlatho

2.1.Mndandanda wa CBS umagwiritsa ntchito mapangidwe a mlatho, ndipo X / Y / Z imakwaniritsa kuyenda kosalekeza, komwe sikumakhudzidwa ndi kulemera kwa A / C axis.

2.2.Mzere wa A / C umagwira ntchito palokha, ndipo kulemera kwa workpiece sikumakhudza mbali zina zitatu.

2.3.Mapangidwe a gantry ndi tebulo la swing ndi rotary lomwe limathandizidwa pamapeto onse awiri lingathe kusunga ndondomeko yolondola kwambiri kwa nthawi yaitali.

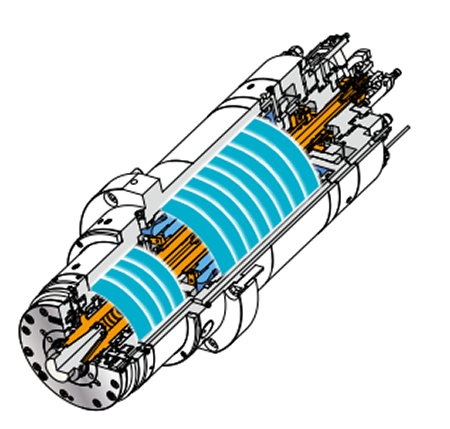

3.Kutembenuza mogwira mtima

4. High-liwiro ndi mkulu-rigidity tebulo rotary amazindikira bwino mphero ndi kutembenuza gulu processing

Gome lozungulira la ma axis asanu lomwe limayendetsedwa mwachindunji ndi torque motor limagwiritsidwa ntchito mu zida zamakina a CNC ndipo limatha kupanga ma axis asanu nthawi imodzi. Ili ndi ubwino wa liwiro lalikulu, kulondola kwambiri, kukhazikika ndi kudalirika, ndi ntchito yosavuta.

5.Kusunga ma spindles olondola kwambiri

Kudziwa matekinoloje oyambira ndikudzipanga paokha ma spindle

Oturn ali ndi luso laukadaulo ndipo ali ndi luso lopanga, kupanga ndi kulumikiza masiponji. Ndi 1000m2 nthawi zonse kutentha msonkhano ndi wotsogola modular chitsanzo kupanga, Oturn spindles ali ndi makhalidwe olimba mkulu, liwiro, mphamvu mkulu, makokedwe mkulu ndi kudalirika mkulu.

The paokha anayamba HSKE40/HSKA63/HSKA100 anamanga-spindle anatengera. Mkati mwa kasinthasintha wa spindle, kugwedezeka ndi kugwedezeka kumachotsedwa kuti akwaniritse kulondola kosasunthika pakukonzekera kwanthawi yayitali komanso kwanthawi yayitali. Spindle imagwiritsa ntchito kuziziritsa kokakamiza kuziziritsa ma mota ndi ma beya akutsogolo ndi akumbuyo.

6.Mapangidwe agalimoto omangidwa

Pochotsa zida zoyendetsera galimoto, kugwedezeka pakasinthasintha kothamanga kumatha kuchepetsedwa, potero kuwongolera kulondola kwa malo opangidwa ndi makina ndikutalikitsa moyo wa chida.

7.Kuwongolera kutentha kwa Spindle

Poyendetsa mafuta oziziritsa omwe amayendetsedwa ndi kutentha, kusuntha kwa kutentha kwa spindle komwe kumachitika chifukwa cha kutentha komwe kumapangidwa ndi chigawo chilichonse kumatha kuponderezedwa, motero kulepheretsa kusintha kwa makina olondola.

8.Kutsogolera dziko lonse mumagetsi ozungulira

Linear motors

8.1.Zokhala ndi mzere woyendetsa galimoto, palibe kukhudzana ndi makina panthawi ya kayendetsedwe kake, palibe kutayika kwa makina, kutayika kwa backlash, komanso kuthamanga kwachangu.

8.2.Absolute optical scale kuti azitha kuyang'anira zonse zotsekedwa.

Mtheradi grating wolamulira, kulondola kwa nanometer-level kuzindikira, kusamvana mpaka 0.05μm, kukwaniritsa zonse zotsekedwa-loop kulamulira.

9.Mapangidwe abwino kwambiri a ergonomic

Kutengera kapangidwe ka ergonomic, ndikosavuta kwa ogwiritsa ntchito kuti agwiritse ntchito ndikuwongolera magwiridwe antchito ndi kusamalitsa.

9.1.Kufikika kwabwino kwambiri

Pofuna kupititsa patsogolo ntchito yofikira pa benchi yogwirira ntchito, chivundikiro pansi pa chitseko cha ntchito chimabwereranso kumbali ya benchi yogwirira ntchito kuti zitsimikizire malo okwanira ogwira ntchito.

Zenera la 9.2.Large kuti muwone mosavuta pokonza

Zenera lalikulu limapangitsa kuti zikhale zosavuta kuwona momwe ntchitoyo ikugwirira ntchito. Makamaka, kutsimikizira pafupipafupi kwa mikhalidwe yodulira ndi kusintha kwa magwiridwe antchito panthawi yosintha kumathanso kutha mosavuta, kuwongolera magwiridwe antchito.

9.3.Kukonzekera kwapakati pazigawo zosamalira

Pofuna kupititsa patsogolo ntchito yofikira pa benchi yogwirira ntchito, chivundikiro pansi pa chitseko cha ntchito chimabwereranso kumbali ya benchi yogwirira ntchito kuti zitsimikizire malo okwanira ogwira ntchito.

9.4.Wide ntchito chitseko kuti mosavuta ndi crane

Pochita ntchito monga kusintha kwa workpiece, ntchito ya ogwira ntchito imatha kuchepetsedwa, ndipo panthawi imodzimodziyo, pali malo okwanira ogwiritsira ntchito pogwiritsa ntchito crane.

9.5.Pleasant ndi wochezeka ntchito gulu

Gulu la opareshoni lozungulira lomwe limagwirizana ndi kutalika kwa thupi la munthu limalola wogwiritsa ntchitoyo kuti agwiritse ntchito ndikukonza makinawo momasuka.

Mfundo Zaukadaulo

| Kanthu | Mtengo wa CBS200 | Zithunzi za CBS200C | Mtengo wa CBS300 | Mtengo wa CBS300C | Mtengo wa CBS400 | Mtengo wa CBS400C | |

| Maulendo | Ulendo wa X/Y/Z wofanana | 300*350*250 | 300*350*250 | 460*390*400 | |||

| Mtunda kuchokera ku nkhope ya spindle kupita ku malo ogwirira ntchito | 130-380 | 130-380 | 155-555 | ||||

| Spindle | Spindle taper | E40 | E40 | E40 | |||

| Kuthamanga kwa Max.spindle | 30000 | 30000 | 30000 | ||||

| Spindle motor motor (yopitilira / S325%) | 11/13.2 | 11/13.2 | 11/13.2 | ||||

| Spindle motor torque (yopitilira / S325%) | 11.5/13.8 | 11.5/13.8 | 11.5/13.8 | ||||

| Dyetsani |

Liwiro lothamanga la X/Y/Z axis (m/min)

| 48/48/48 | 48/48/48 | 30/30/30 | |||

| Kudula chakudya (mm/min) | 1-24000 | 1-24000 | 1-12000 | ||||

| Table yozungulira | Dongosolo la tebulo lozungulira | 200 | 300 | 400 | |||

| Kulemera kololedwa | 30 | 20 | 40 | 25 | 250 | 100 | |

| A-axis tilting angle | ± 110 ° | ± 110 ° | ± 110 ° | ||||

| Kuzungulira kwa C-axis | 360 ° | 360 ° | 360 ° | ||||

| A-axis rated/max.speed | 47/70 | 47/70 | 30/60 | ||||

| A-axis Rated/max.torque | 782/1540 | 782/1540 | 940/2000 | ||||

| C-axis rated/max.speed | 200/250 | 1500/2000 | 200/250 | 1500/2000 | 100/150 | 800/1500 | |

| C-axis rated/max.torque | 92/218 | 15/30 | 92/218 | 15/30 | 185/318 | 42/60 | |

| A-axis positioning kulondola/kubwerezabwereza | 10/6 | 10/6 | 10/6 | ||||

| Kulondola kwa malo a C-axis/kubwerezabwereza | 8/4 | 8/4 | 8/4 | ||||

| ATC | Chida magazini mphamvu | 16 | 16 | 26 | |||

| Chida max. m'mimba mwake/ kutalika | 80/200 | 80/200 | 80/200 | ||||

| Max.chida kulemera | 3 | 3 | 3 | ||||

| Nthawi yosinthira chida (chida kupita ku chida) | 4 | 4 | 4 | ||||

| Atatu- olamulira | X-axis chiwongolero (m'lifupi kalozera) chiwerengero cha slider) | 30/2 | 30/2 | 35/2 | |||

| X-axis chiwongolero (m'lifupi kalozera) chiwerengero cha slider) | 35/2+30/2 | 35/2+30/2 | 45/2 | ||||

| Z-axis chiwongolero (m'lifupi kalozera) chiwerengero cha slider) | 25/2 | 25/2 | 35/2 | ||||

| Mphamvu yamagetsi ya X-axis (yopitilira / max.) | 1097/2750 | 1097/2750 | φ40 × 10 (chikululu) | ||||

| Mphamvu yamtundu wa Y-axis (yopitilira / max.) | 3250/8250 | 3250/8250 |

| ||||

| Z-axis linear motor mphamvu (yopitilira/max.) | 1033/1511 | 1033/1511 |

| ||||

| Kulondola | Kuyika kulondola | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Kubwerezabwereza | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Gwero lamphamvu | Mphamvu yamagetsi | 25 | 30 | 25 | 30 | 30 | 35 |

| Kuthamanga kwa mpweya | ≥0.6Mpa ≥400L/mphindi | ≥0.6Mpa ≥400L/mphindi | ≥0.6Mpa ≥400L/mphindi | ||||

| Kukula kwa makina | Kukula kwa makina | 1920*3030*2360 | 1920*3030*2360 | 2000*2910*2850 | |||

| Kukula kwa makina (kuphatikiza chip conveyor ndi zida zina zotumphukira) | 3580*3030*2360 | 3580*3030*2360 | 3360*2910*2850 | ||||

| Kulemera | 4.8T | 4.8T | 5T | ||||

| Kanthu | Mtengo wa CBS500 | Mtengo wa CBS500C | Mtengo wa CBS650 | Mtengo wa CBS650C | Mtengo wa CBS800 | Mtengo wa CBS800C | |

| Maulendo | Ulendo wa X/Y/Z wofanana | 500*600*450 | 650*800*560 | 800*910*560 | |||

| Mtunda kuchokera ku nkhope ya spindle kupita ku malo ogwirira ntchito | 130-580 | 110-670 | 100-660 | ||||

| Spindle | Spindle taper | A63 | A63 | A63 | |||

| Kuthamanga kwa Max.spindle | 20000 | 20000 | 20000 | ||||

| Spindle motor motor (yopitilira / S325%) | 30/34 | 30/34 | 30/34 | ||||

| Spindle motor torque (yopitilira / S325%) | 47.7/57.3 | 47.7/57.3 | 47.7157.3 | ||||

| Dyetsani | Liwiro lothamanga la X/Y/Z axis (m/min)

| 48/48/48 | 48/48/48 | 48/48/48 | |||

| Kudula chakudya (mm/min) | 1-24000 | 1-24000 | 1-24000 | ||||

| Table yozungulira | Dongosolo la tebulo lozungulira | 500 | 650 | 800 | |||

| Kulemera kololedwa | 600 | 240 | 800 | 400 | 1000 | 400 | |

| A-axis tilting angle | ± 110 ° | ± 110 ° | ± 110 ° | ||||

| Kuzungulira kwa C-axis | 360 ° | 360 ° | 360 ° | ||||

| A-axis rated/max.speed | 60/80 | 40/8C | 40/80 | ||||

| A-axis Rated/max.torque | 1500/4500 | 3500/7000 | 3500/7000 | ||||

| C-axis rated/max.speed | 80/120 | 600/1000 | 50/80 | 450/800 | 50/80 | 450/800 | |

| C-axis rated/max.torque | 355/685 | 160/240 | 964/1690 | 450/900 | 964/1690 | 450/900 | |

| A-axis positioning kulondola/kubwerezabwereza | 10/6 | 10/6 | 10/6 | ||||

| Kulondola kwa malo a C-axis/kubwerezabwereza | 8/4 | 8/4 | 8/4 | ||||

| ATC | Chida magazini mphamvu | 25 | 30 | 30 | |||

| Chida max. m'mimba mwake/ kutalika | 80/300 | 80/300 | 80/300 | ||||

| Max.chida kulemera | 8 | 8 | 8 | ||||

| Nthawi yosinthira chida (chida kupita ku chida) | 4 | 4 | 4 | ||||

| Atatu- olamulira | X-axis chiwongolero (m'lifupi kalozera) chiwerengero cha slider) | 35/2 | 45/2 | 45/2 | |||

| X-axis chiwongolero (m'lifupi kalozera) chiwerengero cha slider) | 45/2 | 45/2 | 45/2 | ||||

| Z-axis chiwongolero (m'lifupi kalozera) chiwerengero cha slider) | 35/2 | 35/2 | 35/2 | ||||

| Mphamvu yamagetsi ya X-axis (yopitilira / max.) | 2167/5500 | 3250/8250 | 3250/8250 | ||||

| Mphamvu yamtundu wa Y-axis (yopitilira / max.) |

|

|

| ||||

| Z-axis linear motor mphamvu (yopitilira/max.) | 2R40*20 (chikululu) | 2R40*20 (chikululu) | 2R40*20 (chikululu) | ||||

| Kulondola | Kuyika kulondola | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Kubwerezabwereza | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Gwero lamphamvu | Mphamvu yamagetsi | 40 | 45 | 55 | 70 | 55 | 70 |

| Kuthamanga kwa mpweya | ≥0.6Mpa ≥400L/mphindi | ≥0.6Mpa ≥400L/mphindi | ≥0.6Mpa ≥400L/mphindi | ||||

| Kukula kwa makina | Kukula kwa makina | 2230*3403*3070 | 2800*5081*3500 | 2800*5081*3500 | |||

| Kukula kwa makina (kuphatikiza chip conveyor ndi zida zina zotumphukira) | 2230*5540*3070 | 2800*7205*3500 | 2800*7205*3500 | ||||

| Kulemera | 11T | 15T | 15.5T | ||||

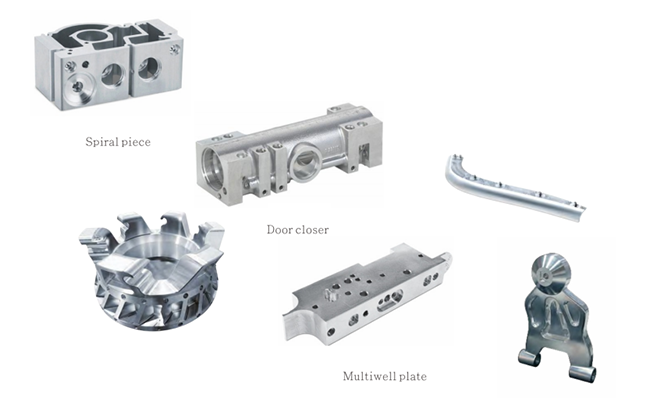

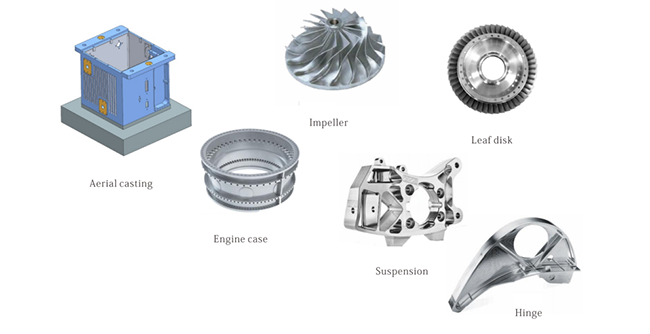

Processing Cases

1. Makampani Agalimoto

2. Zamlengalenga

3.Makina omanga