Makina Obowola a Station Shaft Flange

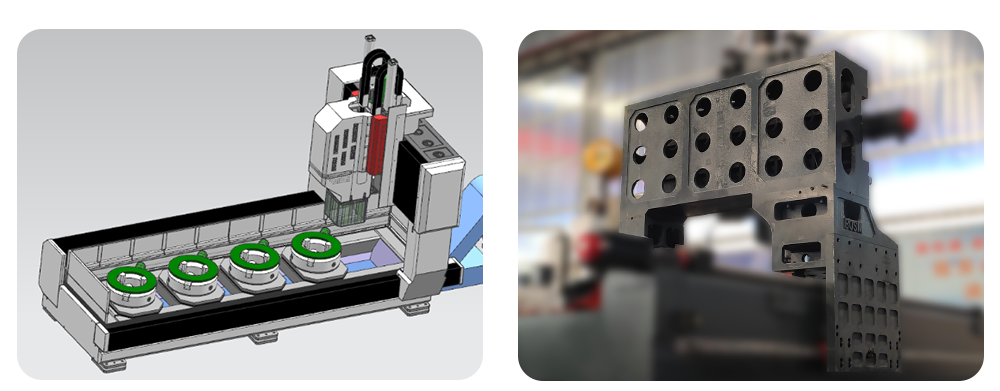

Mawonekedwe a Makina

Makina anayi opangira makina a CNC pobowola ndi makina opangira mphero amagwiritsidwa ntchito kwambiri pobowola flange, ndipo angagwiritsidwenso ntchito pobowola bwino / mphero zogwirira ntchito ndi makulidwe amtundu wothandiza monga ma shafts theka, mbale zosalala, ma flanges, ma disks ndi mphete. / Kugogoda / kubwezeretsanso / kujambula ndi njira zina. Kudzera m'mabowo ndi mabowo akhungu amatha kubowoleredwa pazigawo zosavuta zakuthupi ndi zida zophatikizika. Chida cha makina chimayendetsedwa ndi digito kuti chizigwira ntchito mosavuta. Itha kukwaniritsa zokha, kulondola kwambiri, mitundu ingapo, kupanga misa.

Kapangidwe ka Makina

Makinawa amakhala ndi tebulo logwirira ntchito, ma seti anayi a hydraulic nsagwada zodziyimira pawokha, gantry yam'manja, chishalo chotsetsereka, pobowola ndi mphero, chida chodzitchinjiriza chokha ndi chida choteteza, chipangizo chozizirira chozungulira, makina owongolera digito, ndi dongosolo lamagetsi. Etc composition. Kuthandizira ndi kutsogolera kwa kalozera wa mzere wozungulira ndi chowongolera chowongolera chowongolera, chida cha makina chimakhala ndi malo olondola kwambiri komanso kubwereza kobwerezabwereza.

1. Gome lantchito:

Bedilo limapangidwa ndi zida zachitsulo. Imamalizidwa ndi chithandizo chachiwiri cha kutentha. Ili ndi mphamvu yabwino komanso yosasunthika ndipo siyipunduka. Gome logwirira ntchito limagwiritsa ntchito ma seti anayi a 500mm nsagwada zinayi zodzipangira okha ma hydraulic chucks kuti agwire mwachangu zida zogwirira ntchito. Mawiri awiri owongolera okwera kwambiri amayikidwa mbali zonse za bedi. Pambuyo poyikira, ma seti awiri a kutsekera kokwera kwambiri kochokera kunja Chotchinga champhamvu cha njanji chimayimitsidwa bwino ndikutsekeredwa panjanji. Chotsekeracho chimakwanira bwino popanda kuwononga slider ya njanji. Nthawi yotseka ndikutseka ndi masekondi 0.06 okha, omwe amafupikitsa kwambiri nthawi yokonza. Dongosolo lagalimoto limagwiritsa ntchito basi mtheradi servo motor ndi kulondola Mpira wononga amayendetsa gantry kusuntha njira Y-axis. Maboti osinthika amagawidwa pansi pa bedi, omwe amatha kusintha mosavuta mlingo wa tebulo la bedi.

2.Mobile Gantry:

Gantry yam'manja imaponyedwa ndi chitsulo cha imvi 250. Kutalika kwa mtengo wolemera ndi 800mm kuti awonjezere mphamvu zake. Mawiri awiri otsogola okwera kwambiri amayikidwa kutsogolo kwa gantry. Chotsitsa cha buluu chimagwiritsa ntchito slide yolondola kwambiri ya mpira ndi injini ya servo kusuntha mutu wamphamvu molunjika ku Y axis. A pobowola mphamvu mutu waikidwa pa mphamvu mutu slide. Kusuntha kwa gantry kumazindikiridwa ndi servo motor kuyendetsa mpira wononga mayi kuti azungulire pa mpira wononga kudzera mwatsatanetsatane kulumikizana.

3.Mobile sliding chishalo:

Chishalo chotsetsereka cham'manja ndi gawo lachitsulo chopangidwa mwaluso. Chishalo chotsetsereka chimakulitsidwa ndikuwonjezedwa kuti awonjezere mtunda wapakati wa njanji yowongolera. Ma seti awiri a ultra-high-capacity rolling linear guide njanji ndi ma peyala olondola a mpira amalumikizidwa ndi mkono wolondola kwambiri The brake servo motor imayendetsa mutu wakubowola kuti usunthire mbali ya Z-axis, yomwe imatha kuzindikira mwachangu, patsogolo mafakitale, mofulumira rewind, ndi kuima kwa mutu mphamvu. Ndi automatic chip breaking, kuchotsa chip, kuyimitsa ntchito.

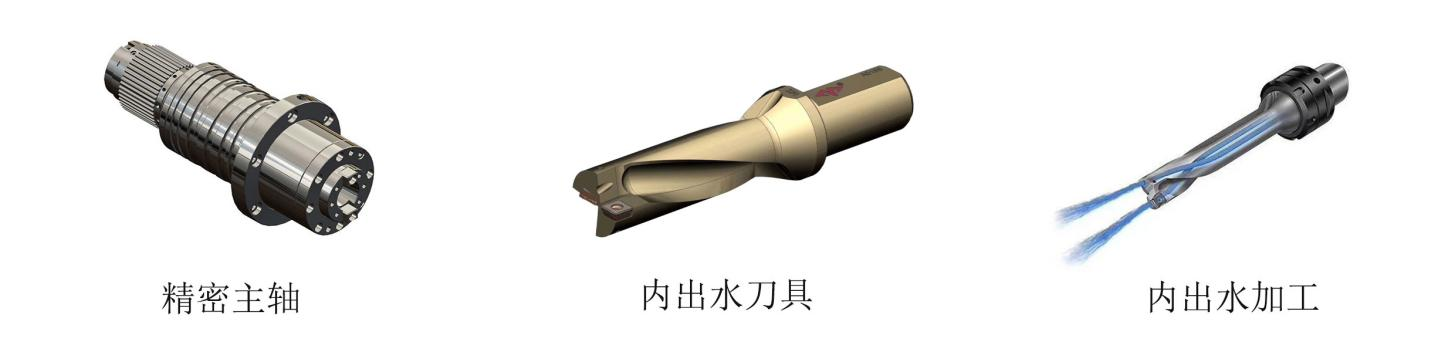

4.Kubowola mutu wa mphamvu:

Mutu wakubowola umagwiritsa ntchito injini yodzipatulira ya servo spindle. Makina opindika olondola amayendetsedwa ndi kutsika kwa lamba wa synchronous lamba kuti awonjezere torque. Spindle imagwiritsa ntchito mizere yakutsogolo itatu, iwiri, ndi mizere isanu yaku Japan kuti ikwaniritse kusintha kosasintha. Kusintha mwachangu komanso kosavuta, chakudyacho chimayendetsedwa ndi servo motor ndi screw screw. Ma axes a X ndi Y amatha kulumikizidwa, ndipo kuwongolera kwa loop kotsekedwa kumatha kugwiritsidwa ntchito kukwaniritsa mizere yozungulira komanso yozungulira.

5. Lathyathyathya unyolo basi Chip conveyor ndi kuzungulira kuzirala chipangizo

Makinawa ali ndi tcheni chathyathyathya cha automatic chip conveyor ndi chotolera tchipisi. Chipangizo chozizira chozungulira chimakhala ndi fyuluta ya pepala, yomwe imakhala ndi mpweya wozizira kwambiri wamkati komanso pampu yoziziritsira kunja kwa kunja kwa mkati ndi kunja kwa chida.

5.1 Chida chodzitchinjiriza chokha ndi chipangizo choteteza:

Makinawa ali ndi chipangizo choyambirira cha ku Taiwan cha volumetric partial pressure automatic automatic, chomwe chimatha kudzoza njanji zowongolera, zomangira zowongolera ndi zina zoyenda, ndipo palibe ngodya yakufa yotsimikizira moyo wa makinawo. X-axis ndi Y-axis yamakina ili ndi zotchingira zoteteza fumbi, ndipo alonda osalowa madzi amayikidwa kuzungulira benchi yogwirira ntchito.

6. CNCcontrol system:

6.1. Ndi chip breaking function, chip breaking time ndi chip breaking cycle zitha kukhazikitsidwa pamakina amunthu.

6.2. Ndi ntchito yokweza chida, kutalika kwa chida kumatha kukhazikitsidwa pamawonekedwe a makina amunthu. Pobowola mpaka kutalika uku, chobowolacho chimakwezedwa mwachangu pamwamba pa chogwirira ntchito, ndiyeno chip chimaphwanyidwa, kenako chimatumizidwa mwachangu kumalo obowola ndikusinthidwa kuti chigwire ntchito.

6.3. Bokosi lapakati loyang'anira ntchito ndi gawo logwirizira m'manja limatenga makina owongolera manambala, ndipo ali ndi mawonekedwe a USB ndi chiwonetsero cha LCD. Pofuna kuwongolera mapulogalamu, kusungirako, kuwonetsera ndi kulankhulana, mawonekedwe ogwiritsira ntchito ali ndi ntchito monga kukambirana ndi makina a munthu, kubwezera zolakwika, ndi alamu yokha.

6.4. Zidazi zimakhala ndi ntchito yowoneratu ndikuwunikanso malo a dzenje musanayambe kukonza, ndipo ntchitoyi ndi yabwino kwambiri.

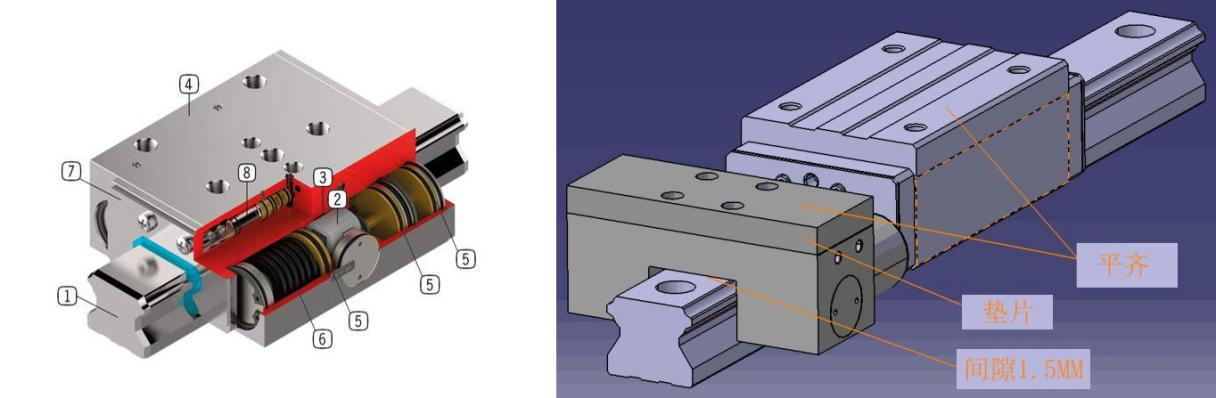

7.Njanji ya njanji:

Choyimitsacho chimapangidwa ndi thupi lalikulu la clamp, actuators, etc. Ndi gawo logwira ntchito kwambiri lomwe limagwiritsidwa ntchito molumikizana ndi gulu lowongolera lozungulira. Kupyolera mu mfundo ya kukulitsa mphamvu ya wedge block force, imapanga mphamvu yokhotakhota yamphamvu; ili ndi gantry yokhazikika, malo enieni, anti-vibration ndi Ntchito kuti ikhale yolimba.

Lili ndi izi:

Ø 1) Otetezeka komanso odalirika, mphamvu yokhotakhota yolimba, kukakamiza XY osasuntha axis pakubowola ndi kukonza.

Ø 2) Mphamvu yokhota mwamphamvu kwambiri imawonjezera kulimba kwa chakudya cha axial ndikuletsa kukhumudwa komwe kumachitika chifukwa cha kugwedezeka.

Ø 3)Kuyankha mwachangu, nthawi yoyankhira ndi kutseka ndi masekondi 0.06 okha, omwe amatha kuteteza chida cha makina ndikuwonjezera moyo wa screw wotsogolera.

Ø 4) Malo okhazikika, okhala ndi faifi tambala, ntchito yabwino yolimbana ndi dzimbiri.

Ø 5)Kapangidwe katsopano kuti mupewe zovuta mukamangika.

Speification

| Chitsanzo | BOSM-DS500 | Chigawo | |

| Kukula kwakukulu kwa workpiece | Akunja awiri | 50-500 | mm |

| Kutalika kwakukulu kwa workpiece | 300 | Kg | |

| Theka shaft workpiece awiri | ≤200 | mm | |

| Kutalika kwa shaft | 700mm akhoza ziwonjezeke malinga ndi maziko | mm | |

| makulidwe a workpiece | ≤5 nthawi za kubowola awiri | mm | |

| Woyima nkhosa yamphongo pobowola mutu wa mphamvu | KTY | 1 | Ma PC |

| Spindle taper | Mtengo wa BT40 | ||

| Drill diameter | Φ2-Φ36 | mm | |

| Kugunda kwamitundu | M6-M24 | ||

| Liwiro la spindle | 30-3000 | r/mm | |

| Servo spindle motor mphamvu | 15 | Kw | |

| Mtunda kuchokera pansi pa spindle kupita ku worktable | 150-550mm±20 | mm | |

| Kusuntha kwapambuyo kwa mutu wamphamvu (X Axis) | MAX. kuyenda | 2600 | mm |

| X liwiro la axis | 0~8 pa | m/mphindi | |

| X Axis servo motor mphamvu | 2.4 | Kw | |

| Kusuntha kwakutali kwa mtengo wosuntha (Y Axis) | MAX. kuyenda | 500 | mm |

| Y axis liwiro | 0~8 pa | m/mphindi | |

| Y Axis servo motor mphamvu | 2.4 | Kw | |

| Kusuntha kwa chakudya chogona (Z axis) | MAX. kuyenda | 400 | mm |

| Z liwiro la axis | 0~4 pa | m/mphindi | |

| Z Axis servo motor mphamvu | 1 × 2.4 brake | Kw | |

| Kuyika kulondola | 500x500 | ± 0.03 | mm |

| Kulondola kwa indexing | 360 ° | ±0.001° | |

| Mtengo wa makina | Utali x m'lifupi x kutalika | 3600×1650×2300 | mm |

| Kulemera kwa makina | 8.5 | T | |

Kuyang'anira Ubwino

Makina aliwonse amawunikidwa ndi laser interferometer yochokera ku kampani ya United Kingdom RENISHAW, yomwe imayang'ana molondola ndikubwezera zolakwika za phula, kubweza kumbuyo, kulondola kwa malo, komanso kutsimikizika kobwerezabwereza kuwonetsetsa kuti makinawo ali osunthika, osasunthika komanso olondola. . Kuyesa kwa bala Mpira Makina aliwonse amagwiritsa ntchito choyesa mpira kuchokera ku kampani yaku Britain ya RENISHAW kukonza kulondola kwa bwalo ndi ma

chine kulondola kwa geometric, ndikuyesa kuyesa kozungulira nthawi imodzi kuti muwonetsetse kuti makina a 3D akulondola komanso kulondola kwa bwalo.

Malo ogwiritsira ntchito chida cha makina

1.1 Zida zofunikira zachilengedwe

Kusunga mulingo wokhazikika wa kutentha kozungulira ndikofunikira kwambiri pakukonza makina.

(1) Kutentha komwe kulipo ndi -10 ℃ ~ 35 ℃. Kutentha kozungulira 20 ℃, chinyezi chiyenera kukhala 40 ~ 75%.

(2) Pofuna kusunga kulondola kwachida cha makina mkati mwazomwe zatchulidwa, kutentha kwabwino kwambiri kumafunika kukhala 15 ° C mpaka 25 ° C ndi kusiyana kwa kutentha.

Siyenera kupitirira ± 2 ℃ / 24h.

1.2 Mphamvu yamagetsi: 3-gawo, 380V, kusinthasintha kwamagetsi mkati mwa ± 10%, ma frequency amagetsi: 50HZ.

1.3 Ngati voteji pamalo ogwiritsira ntchito ndi osakhazikika, chida cha makina chiyenera kukhala ndi magetsi oyendetsedwa bwino kuti atsimikizire kuti makinawo akugwira ntchito bwino.

1.4. Chida cha makina chiyenera kukhala ndi maziko odalirika: waya woyakirapo ndi waya wamkuwa, waya wosachepera 10mm², ndipo kukana kwapansi kumakhala kosakwana 4 ohms.

1.5 Kuti zitsimikizire kuti zida zogwirira ntchito zikuyenda bwino, ngati mpweya woponderezedwa wa gwero la mpweya ukulephera kukwaniritsa zofunikira za gwero la mpweya, zida zoyeretsera mpweya (dehumidification, degreasing, kusefa) ziyenera kuwonjezeredwa pamaso pa mpweya wa makina.

1.6. Zidazi ziyenera kusungidwa kutali ndi kuwala kwa dzuwa, kugwedezeka ndi kutentha, komanso kutali ndi majenereta othamanga kwambiri, makina opangira magetsi, ndi zina zotero, kuti apewe kulephera kupanga makina kapena kutaya makina olondola.

Pamaso & Pambuyo Service

1) Pamaso pa Service

Kupyolera mu phunziro pempho ndi mfundo zofunika kwa makasitomala ndiye ndemanga kwa akatswiri athu, Bossman Technical gulu ndi udindo kulankhulana luso ndi makasitomala ndi mapangidwe mayankho, kuthandiza kasitomala kusankha njira yoyenera Machining ndi makina oyenera.

2) Pambuyo pa Service

A.Makina omwe ali ndi chitsimikizo cha chaka chimodzi ndikulipirira kukonza kwa moyo wonse.

B.Panthawi yachitsimikizo cha chaka chimodzi makinawo atafika padoko, BOSSMAN idzapereka chithandizo chaulere komanso chanthawi yake pazolakwa zosiyanasiyana zomwe sizinapangidwe ndi anthu pamakina, ndikusintha munthawi yake mitundu yonse ya zida zowonongeka zomwe sizinapangidwe ndi anthu. cha malipiro . Zolephera zomwe zimachitika panthawi ya chitsimikizo zidzakonzedwa pamitengo yoyenera.

Thandizo la C.Technical mu maola 24 pa intaneti, TM, Skype, E-mail, kuthetsa mafunso achibale mu nthawi. ngati sizingathetsedwe, BOSSMAN ikonza nthawi yomweyo kuti mainjiniya atagulitsa azifika pamalowo kuti akonzedwe, wogula amayenera kulipira VISA, matikiti oyendetsa ndege ndi malo ogona.

Tsamba la Makasitomala