Makina Olemera a CNC Drilling Milling Machine

CNC Drilling And Milling Machine

Makina othamanga kwambiri a CNC pobowola ndi mphero

Kugwiritsa Ntchito Makina

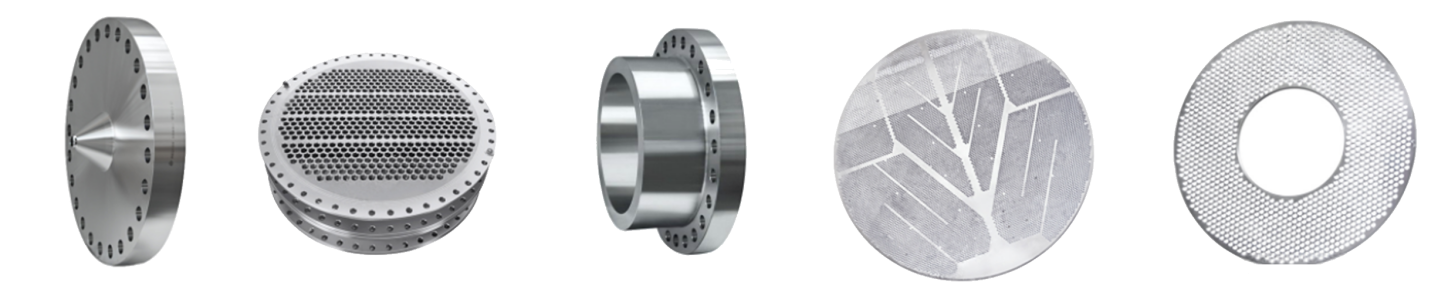

CNC pobowola ndi makina mphero zimagwiritsa ntchito pobowola imayenera ya workpieces ndi makulidwe mkati bwino osiyanasiyana monga mbale, flanges, disks ndi mphete. Kudzera m'mabowo ndi mabowo akhungu amatha kubowola pamitundu yosiyanasiyana ya zida. Makinawa amawongoleredwa ndi digito ndi ntchito yosavuta. Itha kukwaniritsa zokha, kulondola kwambiri, mitundu ingapo, kupanga misa.

Pofuna kukwaniritsa zosowa za ogwiritsa ntchito osiyanasiyana, kampani yathu yapanga makina osiyanasiyana. Kuwonjezera zitsanzo ochiritsira, angathenso makonda malinga ndi zosowa zenizeni za makasitomala.

Kapangidwe ka Makina

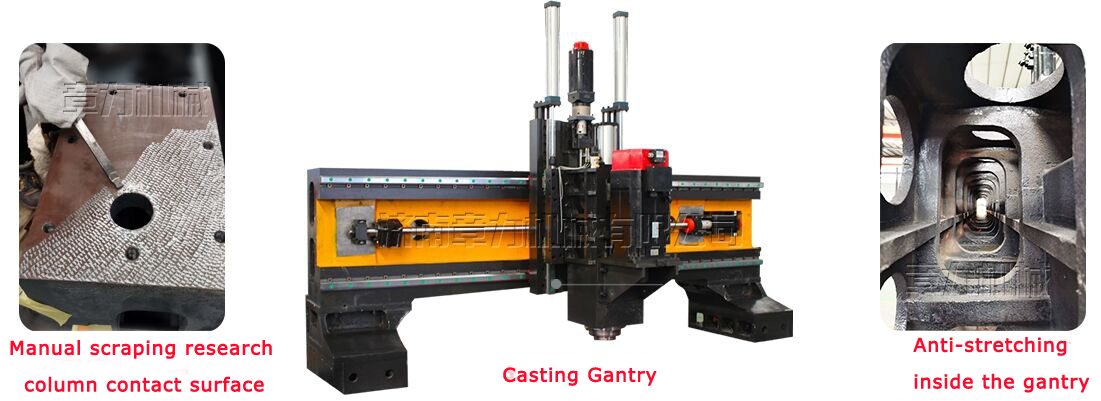

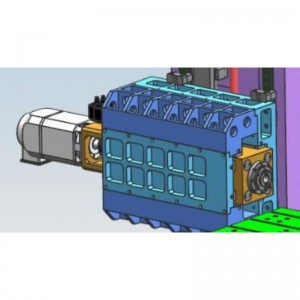

Chida ichi chimapangidwa makamaka ndi tebulo la bedi, gantry yosuntha, chishalo chotsetsereka, kubowola ndi mphero spindle, chipangizo chopangira mafuta ndi zoteteza, chipangizo chozizira chozungulira, makina owongolera a CNC, makina amagetsi ndi zina zotero. Kuthandizira ndi kuwongolera kwa kalozera wopukutira ndi chowongolera chowongolera chowongolera, makinawo ali ndi malo olondola kwambiri komanso kulondola kobwerezabwereza.

1)Ntchito:

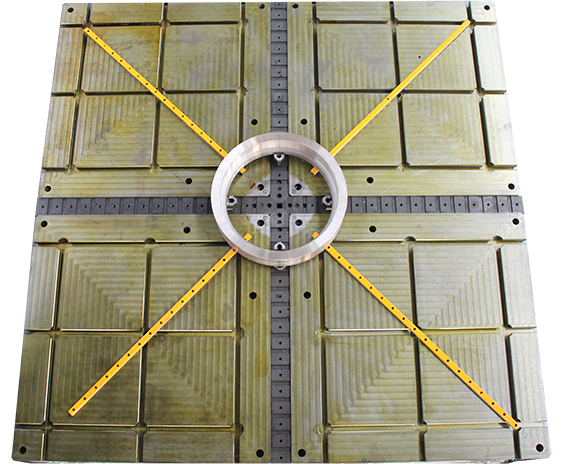

Gome logwirira ntchito limagwiritsa ntchito mawonekedwe oponyera, ndipo ndegeyo ili ndi T-slot yokhala ndi mawonekedwe omaliza a clamping workpieces. Pamwamba pa bedi, ma T-slots amakonzedwa. Dongosolo loyendetsa limagwiritsa ntchito AC servo mota ndi wononga mpira wolondola kuyendetsa mbali zonse kuti chiwongolerocho chisunthike ku Y-axis. Maboti osinthika amagawidwa pansi pa bedi, omwe amatha kusintha mosavuta mlingo wa tebulo la bedi.

2)Movesigantry:

Gantry yam'manja imayikidwa ndi chitsulo chotuwa 250, ndipo awiri awiri otsogola apamwamba kwambiri amayikidwa kutsogolo kwa gantry. Seti ya slide yolondola kwambiri ya mpira ndi injini ya servo imapangitsa kuti mutu wamphamvu usunthike kulowera ku X-axis. A pobowola mphamvu mutu waikidwa pa mphamvu mutu slide. Kusuntha kwa gantry kumazindikiridwa ndi servo motor kuyendetsa waya wa mpira pa phula la mpira kudzera pakulumikiza molondola.

3)Movesisliding chishalo:

Chishalo chotsetsereka cham'manja ndi gawo lachitsulo chopangidwa mwaluso. Ma slide awiri a njanji apamwamba kwambiri a NC ndi seti ya ma screw pairs olondola kwambiri komanso chochepetsera mapulaneti olondola kwambiri amalumikizidwa ndi injini ya servo kuyendetsa mutu wamagetsi obowola. Kusunthira mbali ya Z-axis kumatha kuzindikira mwachangu, kupita patsogolo, kubwerera m'mbuyo mwachangu, ndikuyimitsa mutu wamagetsi. Ndi automatic chip breaking, kuchotsa chip, kuyimitsa ntchito.

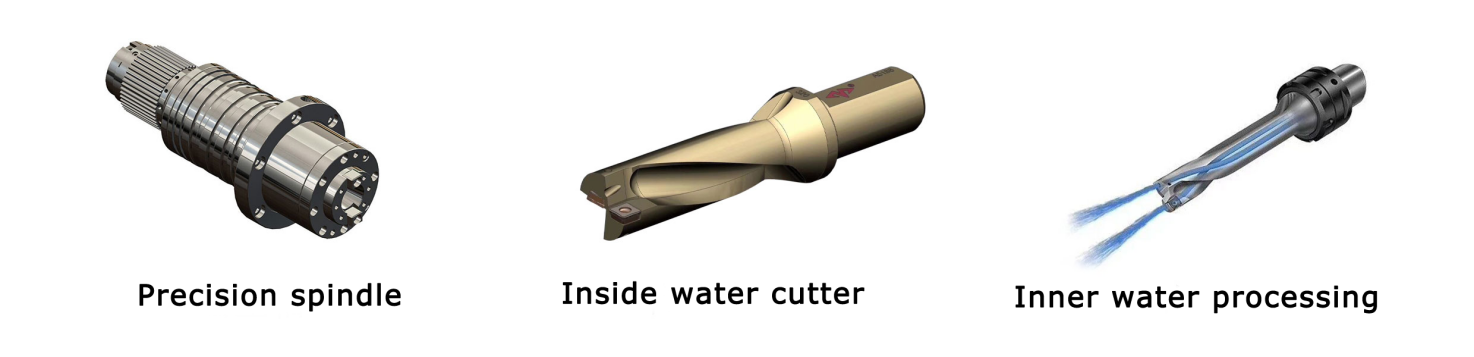

4)Kubowola mphamvu mutu(Spindle):

Mutu wakubowola umagwiritsa ntchito injini yodzipatulira ya servo spindle, yomwe imayendetsa spindle yodzipatulira potsitsa lamba wa synchronous wa mano kuti awonjezere torque. Spindle imagwiritsa ntchito mizere yakutsogolo itatu, iwiri, ndi mizere isanu yaku Japan kuti ikwaniritse kusintha kosasintha. Kusintha mwachangu komanso kosavuta, chakudyacho chimayendetsedwa ndi servo motor ndi screw ya mpira. Ma axes a X ndi Y amatha kulumikizidwa, ndipo kuwongolera kwa loop kotsekeka kumagwiritsidwa ntchito kukwaniritsa mizere yozungulira komanso yozungulira.

Spindle end ndi BT40 tapered hole, yokhala ndi Rotorfoss high-speed rotary joint from Italy, that can use high-liwiro U kubowola (zachiwawa kubowola) ndi pachimake kubowola pobowola madzi kutulutsa madzi. kuzindikira zakuya dzenje processing ndi kuteteza chida kuchepetsa ntchito mtengo.

5)Chida chodzitchinjiriza chokha komanso chida choteteza:

monga njanji zowongolera, zomangira zotsogola, zoyikapo, ndi zina zambiri, zopanda ngodya zakufa kuti zitsimikizire moyo wautumiki wa chida cha makina. X-axis ndi Y-axis yamakina ili ndi zotchingira zoteteza fumbi, ndipo alonda osalowa madzi amayikidwa kuzungulira benchi yogwirira ntchito.

6)CNC Control System:

6.1Ndi ntchito yothyola chip, nthawi yothyola chip ndi kuzungulira kwa chip kumatha kukhazikitsidwa pamawonekedwe a makina amunthu.

6.2 Ndi ntchito yokweza chida, kutalika kwa chida kumatha kukhazikitsidwa pamakina amunthu. Pobowola mpaka kutalika uku, kubowolako kumakwezedwa mwachangu pamwamba pa chogwiriracho, ndiyeno chip chimaponyedwa, kenako chimatumizidwa mwachangu kumalo obowola ndikusinthidwa kuti chigwire ntchito.

6.3 The centralized ntchito kulamulira bokosi ndi dzanja wogwirizira unit kutengera manambala kulamulira dongosolo, ndipo okonzeka ndi USB mawonekedwe ndi LCD madzi galasi kuwonetsera. Pofuna kuwongolera mapulogalamu, kusungirako, kuwonetsera ndi kulankhulana, mawonekedwe ogwiritsira ntchito ali ndi ntchito monga kukambirana ndi makina a munthu, kubwezera zolakwika, ndi alamu yokha.

6.4Makinawa ali ndi ntchito yowoneratu ndikuwunikanso malo a dzenje musanayambe kukonza, ndipo ntchitoyi ndi yabwino kwambiri.

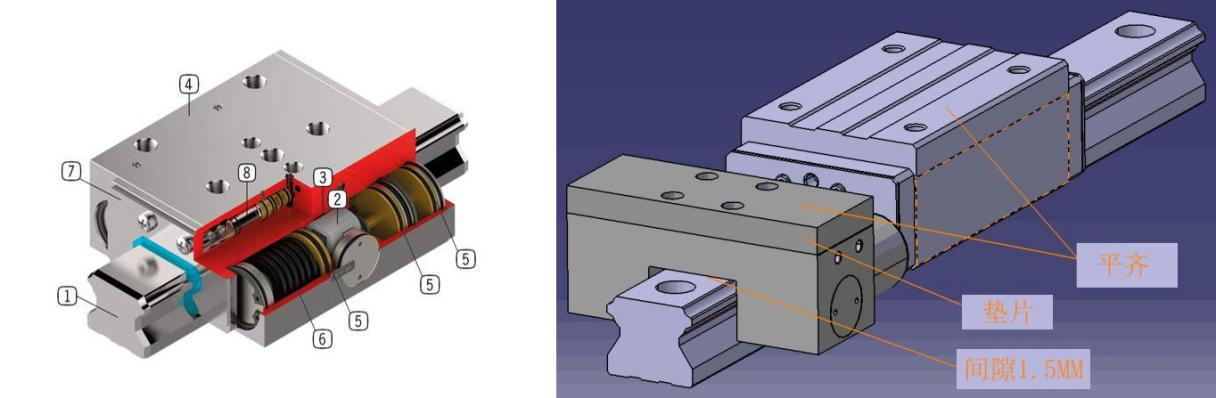

7)Chipani cha njanji

Chophimbacho chimapangidwa ndi thupi lochepetsera komanso chowongolera. Ndi gawo logwira ntchito kwambiri lomwe limagwiritsidwa ntchito limodzi ndi gulu lowongolera. Zimapanga mphamvu yokhotakhota yolimba kudzera mu mfundo yokulitsa chipika. Zinthu zomwe zimawonjezera kuuma.

Mawonekedwe:

- Otetezeka komanso odalirika, mphamvu yokhotakhota yolimba, yomangirira osasuntha axis ya XY pakubowola ndi kukonza.

- Mphamvu yokhotakhota kwambiri, imawonjezera kulimba kwa chakudya cha axial, ndikuteteza kusuntha kwakung'ono komwe kumachitika chifukwa cha kugwedezeka.

- Kuyankha mwachangu, kutsegula ndi kutseka nthawi yoyankha ndi masekondi 0.06 okha, omwe amateteza chida cha makina ndikuwongolera moyo wa screw.

- Chokhazikika, chokutidwa ndi faifi tambala, ntchito yabwino yolimbana ndi dzimbiri.

Kapangidwe katsopano kuti mupewe zovuta mukamangirira.

8)Makina ochotsamo chip ndi chipangizo chozizirira chozungulira:

Chotsitsa chodziwikiratu cha chip chimakonzedwa kumbuyo kwa benchi yogwirira ntchito ndipo fyuluta imakonzedwa kumapeto. Chotsitsa cha automatic chip ndi mtundu wa tcheni chathyathyathya, ndipo pampu yozizirira imayikidwa mbali imodzi. Kutuluka kwa chip kumalumikizidwa ndi dongosolo losefera madzi. Choziziritsa chimalowa mu ejector ya chip. Pampu yokweza chip ejector imayendetsa choziziritsa kukhosi mkati mwa makina osefera apakati. Pampu yozizirira yothamanga kwambiri imazungulira choziziritsira chosefedwa chodulira ndi kuziziritsa. Ndipo ili ndi trolley yonyamula chip, yomwe ndi yabwino kwambiri kunyamula tchipisi tachitsulo. Zidazi zili ndi makina ozizira amkati ndi kunja kwa ocheka. Pobowola pa liwiro lalikulu, odulawo amatsitsidwa ndi madzi amkati ndi kunja panthawi ya mphero.

Alamu yamadzi otsika

1) Chozizirira mu fyuluta chikafika pakatikati mwamadzimadzi, makinawo amalumikiza injini kuti iyambike, ndipo choziziritsa kukhosi mu chochotsa chip chimangoyenderera mu fyuluta. Pamene mulingo wamadzimadzi wapamwamba wafika, mota imasiya kugwira ntchito.

2) Choziziritsa mu fyuluta chikafika potsika, makinawo amangopangitsa kuti mulingo wamadzimadzi ukhale alamu, spindle imangochotsa chidacho, ndipo makinawo adzayimitsa ntchito.

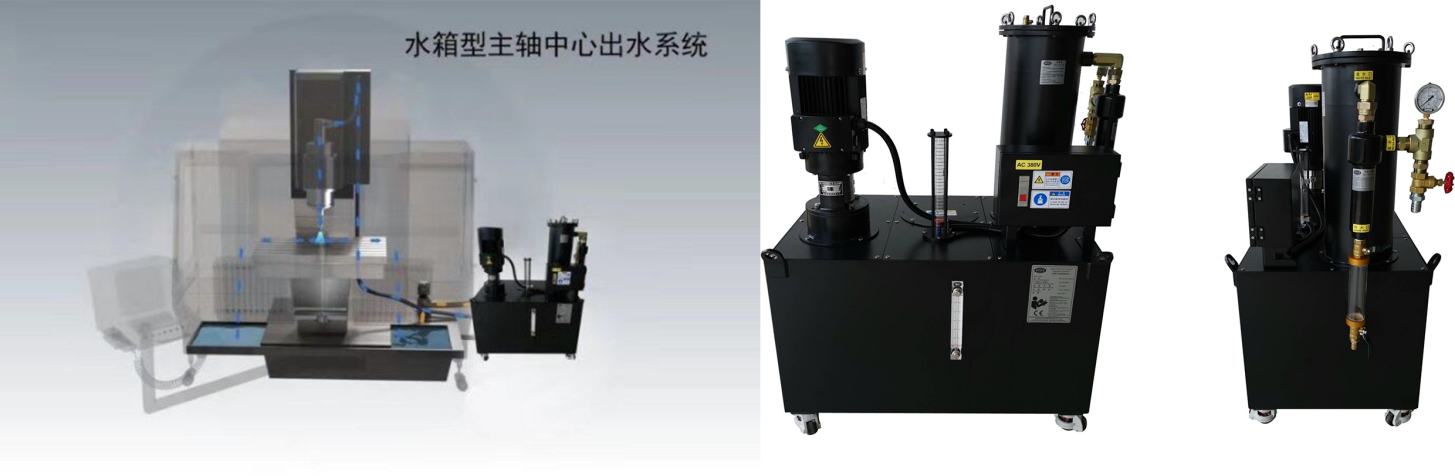

9)Central Outlet Sefa System:

Makinawa ali ndi makina apakati osefera madzi monga muyezo, omwe amatha kusefa zonyansa muzoziziritsa kukhosi. Dongosolo lamadzi lopopera lamkati lingalepheretse zikhomo zachitsulo kuti zisagwedezeke pa chida pakukonza, kuchepetsa kuvala kwa zida, kukulitsa moyo wa chida, kuwongolera kumaliza kwa workpiece, Pini yotulutsa madzi yothamanga kwambiri pansonga ya tsamba imatha kuteteza pamwamba pa workpiece, tetezani cholumikizira chothamanga kwambiri, tetezani zonyansa kuti zisatseke cholumikizira chozungulira, ndikuwongolera magwiridwe antchito onse komanso magwiridwe antchito.

10)Mpira screw ndi motor Integrated mpando:

Base ya injini ndi chinthu chokhazikika kwambiri cholumikiza wononga mpira ndi mota. Kulumikizana kozungulira kozungulira kozungulira (kulondola kalasi C5) kumaphatikizidwa kuti kuwongolera kulondola ndikuwonetsetsa kuti zero axial chilolezo cha screw ya mpira pomwe mota ikupita patsogolo ndikubwerera. Ndizoyenera makamaka pazida zothamanga kwambiri.

Kulondola kwa msonkhano: wononga mpira ndi mota zimayikidwa m'modzi kudzera m'munsi mwagalimoto. Chepetsani zolakwika za shaft ya motor shaft ndi shaft screw shaft, ziwongolereni pakuwonjezera kapena kuchotsera 0.01mm, ndipo mawonekedwe a nkhope yakumapeto ndi 0.01.

11)Gome lazikhadabo zinayi(posankha)

The worktable of self-centering equipment ili ndi four-jaw hydraulic self-centering chuck. The workpiece akhoza kukhala pakati basi mu achepetsa chimodzi popanda workpiece aliyense kulondera kupeza pakati. The clamping ndi yachangu komanso yabwino.

Kuthetsa vuto kuti chidutswa ntchito ndi indexing bwalo zosakwana 1600 mm awiri ndi clamped ndi kukanikiza mbale pambuyo kudyetsa ndiyeno kufunafuna pakati, amene amadya nthawi yocheperapo ndipo amatenga nthawi yaitali clamping kuposa processing nthawi.

Chuck yodziyimira payokha ya nsagwada zinayi yokhazikika yokhazikika yokhala ndi sitiroko yayikulu ya nsagwada zimapangitsa kuti zikhale zovuta kuti workpiece igwire nsagwada ikamangirira. Chojambula chojambula chokhala ndi pad chimagwiritsidwa ntchito.Imathetsa vutoli kuti nsagwada za hydraulic kapena pneumatic sizikuyenda pang'ono pamsika ndipo zogwirira ntchito zazikulu zidzakhudza nsagwada pamene mukukweza, kuwononga ma chucks.

Nsagwada zinayi pa benchi yogwirira ntchito zili mu kalembedwe ka disassemblable, ndipo kuchotsedwa kwa workbench kumbuyo ndi nsanja yachibadwa ndi T-groove yake.

Specificationn

| Chitsanzo | Chithunzi cha BOSM-DT1010 | Chithunzi cha BOSM-DT2010 | BOSM-DT2016 | Chithunzi cha BOSM-DT2525 | |

| Kugwira ntchito | Utali*Utali (mm) | 1000x1000 | 2000x1000 | 2000x1600 | 2500x2500 |

| Mutu Wobowola Woima | Spindle taper | BT40/BT50 | BT40/BT50 | BT40/BT50 | BT40/BT50 |

| Kubowola m'mimba mwake (mm) | Φ40/Φ60 | Φ40/Φ60 | Φ40/Φ60 | Φ40/Φ60 | |

| Kutalika kwapakati (mm) | M24/M36 | M24/M36 | M24/M36 | M24/M36 | |

| Liwiro la spindle (r/min) | 30-3000 | 30-3000 | 30-3000 | 30-3000 | |

| Mphamvu ya spindle (Kw) | 15/22 | 15/22 | 15/22 | 15/22 | |

| Mtunda kuchokera pansi kumapeto kwa spindle kupita kumalo ogwirira ntchito (mm) | 200 ~ 600 / 400 ~ 800 | 200 ~ 600 / 400 ~ 800 | 200 ~ 600 / 400 ~ 800 | 200 ~ 600 / 400 ~ 800 | |

| Bweretsani Kulondola Kwamayimidwe (X/Y/Z) | X/Y/Z | ± 0.01/1000mm | ± 0.01/1000mm | ± 0.01/1000mm | ± 0.01/1000mm |

| Kulemera kwakukulu (T) | 8.5 | 11 | 13.5 | 16.5 | |

| Chida chamagazini | Line chida magazini | ||||

Kuyang'anira Ubwino

Makina aliwonse a Bosman amayesedwa ndi laser interferometer yochokera ku kampani ya United Kingdom RENISHAW, yomwe imayang'ana molondola ndikubwezera zolakwika za phula, kubweza, kulondola kwa malo, komanso kukhazikika kobwerezabwereza kuwonetsetsa kuti makinawo ndi amphamvu, osasunthika komanso olondola. . Mpira bala mayeso Makina aliwonse amagwiritsa ntchito choyesera mpira kuchokera ku kampani yaku Britain ya RENISHAW kukonza kulondola kwa bwalo lolondola ndi makina olondola a geometric, ndikuchita zoyeserera zodulira zozungulira nthawi imodzi kuti zitsimikizire kulondola kwa makina a 3D ndi kulondola kwa bwalo.

Pamaso & Pambuyo Service

1) Pamaso pa Service

Kupyolera mu phunziro pempho ndi mfundo zofunika kwa makasitomala ndiye ndemanga kwa akatswiri athu, Bossman Technical gulu ndi udindo kulankhulana luso ndi makasitomala ndi mapangidwe mayankho, kuthandiza kasitomala kusankha njira yoyenera Machining ndi makina oyenera.

2) Pambuyo pa Service

A.Makina omwe ali ndi chitsimikizo cha chaka chimodzi ndikulipirira kukonza kwa moyo wonse.

B.Panthawi yachitsimikizo cha chaka chimodzi makinawo atafika padoko, BOSSMAN idzapereka chithandizo chaulere komanso chanthawi yake pazolakwa zosiyanasiyana zomwe sizinapangidwe ndi anthu pamakina, ndikusintha munthawi yake mitundu yonse ya zida zowonongeka zomwe sizinapangidwe ndi anthu. cha malipiro . Zolephera zomwe zimachitika panthawi ya chitsimikizo zidzakonzedwa pamitengo yoyenera.

Thandizo la C.Technical mu maola 24 pa intaneti, TM, Skype, E-mail, kuthetsa mafunso achibale mu nthawi. ngati sizingathetsedwe, BOSSMAN ikonza nthawi yomweyo kuti mainjiniya atagulitsa azifika pamalowo kuti akonzedwe, wogula amayenera kulipira VISA, matikiti oyendetsa ndege ndi malo ogona.

Tsamba la Kampani