5-Axis Vertical Machining Center V5-320B

1. Mapangidwe onse a chida cha makina

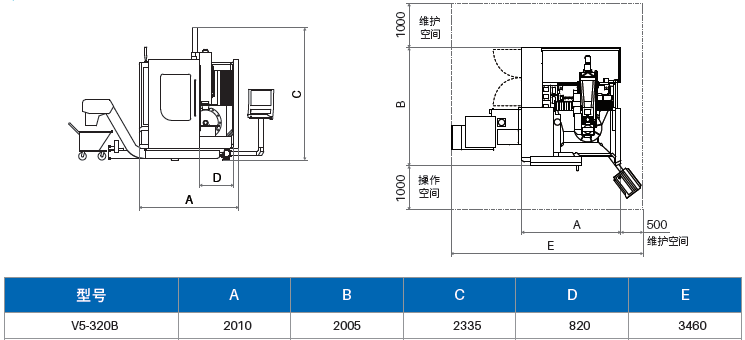

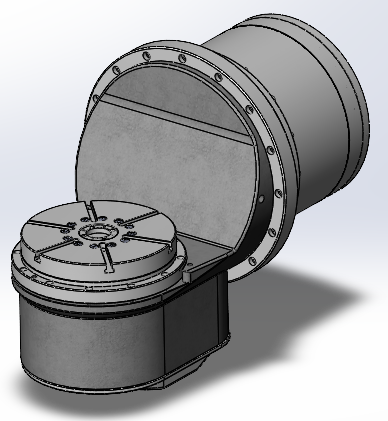

Malo opangira makina a V5-320B asanu-axis amatenga chokhazikika chooneka ngati C, ndimeyi imakhazikika pabedi, mbale yolowera imasuntha mozungulira pamzake (X direction), mpando wa slide umayenda motalika motsatira mbale ya slide (Y direction). ), ndipo mutuwo umayenda molunjika pampando wa slide ( Z direction). Gome logwira ntchito limagwiritsa ntchito njira yodzipangira yokha yoyendetsa galimoto imodzi yokha, ndipo zizindikiro zake zosiyanasiyana zogwirira ntchito zafika pamtunda wapadziko lonse.

2. Dongosolo la chakudya

X, Y, Z-axis linear guide njanji ndi zomangira za mpira, kukangana kwakung'ono kosunthika komanso kosasunthika, kumva kwambiri, kunjenjemera kwakung'ono kothamanga kwambiri, osakwawa pa liwiro lotsika, malo olondola kwambiri, komanso magwiridwe antchito abwino kwambiri a servo drive.

Ma X, Y, Z-axis servo motors amalumikizidwa mwachindunji ndi zomangira zolondola kwambiri za mpira ndi zolumikizira, kuchepetsa maulalo apakatikati, kuzindikira kufalikira kwapang'onopang'ono, kudyetsa kosinthika, kuyika kolondola, komanso kulondola kwambiri.

Z-axis servo motor ili ndi ntchito yoboola. Mphamvu ikatha, brake imatha kugwira shaft yamotoyo mwamphamvu kuti isamazungulira, zomwe zimagwira ntchito yoteteza chitetezo.

3. Nsonga yamagetsi

Spindle yamagetsi imagwiritsa ntchito spindle yamagetsi yodzipangira yokha (yopanga patent: 202010130049.4), ndipo mapeto ake amakhala ndi ma nozzles ozizira kuti aziziziritsa chida. Ili ndi maubwino a liwiro lalikulu, kulondola kwambiri, komanso kuyankha kwamphamvu kwambiri, ndipo imatha kuzindikira kuwongolera mwachangu. Encoder yomangidwa mwapamwamba kwambiri imatha kuzindikira kuyimitsidwa kolondola komanso kugogoda kosasunthika.

4. Magazini ya zida

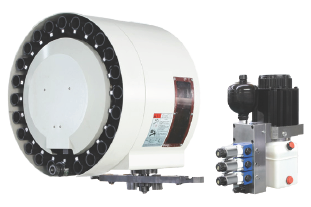

Magazini ya chida chamtundu wa BT40, malo a zida 24, kusintha kwa zida zodziwikiratu ndi ATC manipulator.

Onani pansipa:

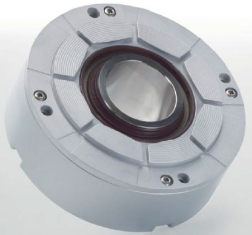

5. Turntable

Imatengera kamangidwe kamene kamakhala kamene kamakhala kamene kamakhala ndi mkono umodzi, kamene kali ndi ubwino wokhazikika kwambiri, kulondola kwambiri komanso kuyankha kwamphamvu kwambiri.

| Mzere | Adavotera Torque Nm | Adavotera Speed rpm | Max. liwiro rpm | Adavotera Panopo A | Adavotera Mphamvu kW |

| B | 656 | 80 | 100 | 18 | 5.5 |

| C | 172 | 100 | 130 | 6.1 | 1.8 |

6. Dongosolo la mayankho otsekedwa kwathunthu

X, Y, ndi Z nkhwangwa zofananira zili ndi HEIDENHAIN LC4 mndandanda wa masikelo amtengo wapatali; Matebulo a B ndi C ali ndi ma encoder a HEIDENHAIN RCN2000 mndandanda wamtengo wapatali kuti azindikire mayankho otsekeka a nkhwangwa 5 zodyera, kuwonetsetsa kuti chida chamakina chimakhala cholondola kwambiri komanso cholondola kwambiri. kusungidwa kolondola.

7. Kuzizira ndi pneumatic system

Wokhala ndi choziziritsa kumadzi kuti azizizira nthawi zonse kuti atsimikizire kuti spindle yamagetsi ndi Direct drive turntable zili bwino kugwira ntchito ndipo zimatha kuyenda bwino kwa nthawi yayitali.

Dongosolo la pneumatic limasefedwa ndi zigawo za pneumatic kuti zizindikire ntchito zotsuka ndi kuwomba dzenje la tsinde lalikulu, chitetezo chosindikizira mpweya chamtundu waukulu wa shaft, ndikutembenuzira magazini ya chida ndi chogwiritsira ntchito.

8. Centralized lubrication dongosolo

Malo otsetsereka a njanji yowongolera ndi mtedza wa wononga mpira amatengera chipangizo chapakati chokhala ndi mafuta opyapyala, omwe amapereka mafuta okhazikika komanso ochulukirapo kuti atsimikizire kulondola komanso kukhazikika kwa wononga mpira ndi njanji yowongolera.

9. Njira yoyezera ntchito

Chida cha makina chimakhala ndi kafukufuku wokhudza HEIDENHAIN TS460 ndi cholandila opanda zingwe, chomwe chitha kukhazikitsidwa pa spindle kudzera pamanja kapena makina osinthira zida kuti azindikire ntchito za mayanidwe a workpiece, muyeso wa workpiece ndi kukhazikitsidwa kwa mfundo, ndipo muyeso wobwereza ndi ≤ 1um (kufufuza liwiro 1 m/min), kutentha kwa ntchito ndi 10°C mpaka 40°C. The HEIDENHAIN touch probe imayambitsidwa ndi switch ya kuwala. Cholembera chimagwiritsa ntchito nsonga zitatu kuti zitsimikizire malo abwino omasuka. Ndiwopanda kuvala panthawi yogwiritsidwa ntchito, imakhala yobwerezabwereza komanso imakhala yokhazikika kwa nthawi yaitali.

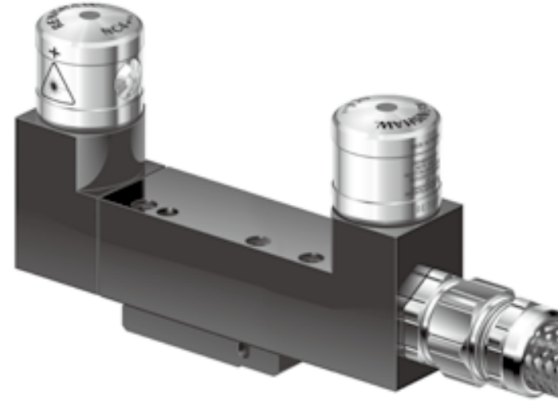

10. Chida choyezera dongosolo

Chida cha makinacho chili ndi chida cha Renishaw NC4 laser chokhazikitsa chida, kuyeza kubwereza ndi ± 0.1um, ndipo kutentha kwa ntchito ndi 5 ° C mpaka 50 ° C.

11. Kuwongolera kolondola kwa ma axis asanu

Chida cha makinacho chimakhala ndi mipira yoyeserera ya KKH yochokera ku HEIDENHAIN, pamodzi ndi ma probes a TS, kuti akwaniritse kuwongolera kolondola kwa makina ozungulira axis, kuchepetsa zolakwika pakuyenda kwa zida zamakina, ndikukwaniritsa kulondola kwambiri komanso kubwereza kwambiri.

12. Chitetezo cha chida cha makina

Chida chamakina chimatengera chivundikiro chodzitchinjiriza chomwe chimakwaniritsa miyezo yachitetezo kuti chiteteze kuziziritsa ndi tchipisi kuti zisagwe, kuonetsetsa kuti zikuyenda bwino, komanso kukhala ndi mawonekedwe osangalatsa. Chiwongolero cha X cha chida cha makina chimakhala ndi chishango chankhondo, chomwe chingateteze bwino njanji yowongolera ndi wononga mpira.

13. Zida zogwirira ntchito za makina

(1) Mphamvu yamagetsi: 380V±10% 50HZ±1HZ magawo atatu AC

(2) Kutentha kwapakati: 5°C-40°C

(3) Kutentha koyenera: 22°C-24°C

(4) Chinyezi chachibale: 20-75%

(5) Kuthamanga kwa mpweya: ≥6 bar

(6) Kuthamanga kwa gasi: 500 L / min

14. Ntchito yoyambitsa dongosolo la CNC

HEIDENHAIN TNC640 CNC dongosolo

(1) Chiwerengero cha nkhwangwa: mpaka 24 malupu owongolera

(2) Mtundu wokhudza zenera wokhala ndi magwiridwe antchito ambiri

(3) Kulowetsa pulogalamu: Kukambirana kwa Klartext ndi G code (ISO).

(4) FK pulogalamu yaulere ya contour: gwiritsani ntchito chilankhulo cha Klartext polankhula kuti mupange pulogalamu yaulere ya FK mothandizidwa ndi zithunzi.

(5) Kuchuluka kwa mphero ndi kubowola

(6) Chida chamalipiro: chiwongola dzanja cha radius chida ndi kubweza kutalika kwa chida. Probe kuzungulira

(7) Kudula deta: Kuwerengera modzidzimutsa kwa liwiro la spindle, liwiro la kudula, chakudya pa tsamba ndi chakudya pa bwalo

(8) Kuthamanga kosalekeza kwa contour: zokhudzana ndi njira ya chida chapakati / wachibale ndi m'mphepete mwa zida

(9) Parallel Run: Pulogalamu yokhala ndi chithandizo chazithunzi pomwe pulogalamu ina ikuyenda

(10) Zinthu zozungulira: mzere wowongoka/chamfer/njira ya arc/pakati/pakati/bwalo lozungulira/malo ozungulira ozungulira/olumikizana mozungulira ngodya yozungulira

(11) Kuyandikira ndikuchoka pamakona: tangential kapena perpendicular / kudutsa njira za arc

(12) Kudumpha kwa pulogalamu: kubwereza kwa pulogalamu yapang'onopang'ono / pulogalamu iliyonse ikhoza kukhala yocheperako

(13) Kuzungulira kwam'zitini: kubowola, kubowola, kugogoda (kapena popanda chimango choyandama choyandama), makona anayi ndi arc. Peck kubowola, reming, wotopetsa, malo moyang'ana, pobowola malo. Kugaya ulusi wamkati ndi kunja. Kukokera kwa malo athyathyathya komanso opendekera. Kukonzekera kwathunthu kwa matumba amakona anayi ndi ozungulira, mabwana amakona anayi ndi ozungulira. Zozungulira zozungulira komanso zowongoka zowongoka komanso zozungulira. Lembani mfundo zozungulira ndi mizere. Malo oyambira: QR code. Contour chain, Contour thumba. Contour groove kwa trochoidal mphero. Engraving kuzungulira: jambulani mawu kapena manambala molunjika kapena arc.

(14) Gwirizanitsani kusinthika: kumasulira, kuzungulira, kuyang'ana pagalasi, makulitsidwe (njira yeniyeni).

(15) Q parameter variable programming: masamu, ntchito zomveka, ntchito ya makolo, mtengo wathunthu, þ yosalekeza, kukana, chiwerengero kapena decimal, ntchito yowerengera mozungulira, ntchito yolemba malemba.

(16) Zothandizira pulogalamu: chowerengera. Mndandanda wa mauthenga onse olakwika omwe alipo. Thandizo lokhala ndi vuto la mauthenga olakwika. TNCguide: dongosolo lothandizira lophatikizika; TNC 640 imawonetsa zambiri kuchokera ku bukhu la ogwiritsa ntchito. Thandizo lojambula pamapulogalamu ozungulira. Ndemanga ndi midadada yayikulu mu mapulogalamu a NC.

(17) Kupeza chidziwitso: gwiritsani ntchito mwachindunji malo enieni mu pulogalamu ya NC.

(18) Zithunzi zotsimikizira pulogalamu: Kuyerekezera kojambula kwa makina opangira makina kumatha kuchitidwa ngakhale pulogalamu ina ikugwira ntchito. Mawonedwe apamwamba/mawonekedwe atatu-atatu/mawonedwe a sitiriyo, ndi ndege yokhazikika yokonza/mizere ya 3-D. Kukweza kwanuko.

(19) Thandizo lazithunzi za pulogalamu: Ngakhale pulogalamu ina ikugwira ntchito, zithunzi (zojambula pamanja za 2-D) za gawo la pulogalamu ya NC zolowetsamo zitha kuwonetsedwa munjira yosinthira pulogalamu.

(20) Pulogalamu yojambula zithunzi: zojambula zenizeni zenizeni pamene mukuchita pulogalamu ya mphero. mawonekedwe apamwamba/mawonedwe atatu/mawonedwe a stereo.

(21) Nthawi yokonza: Werengani nthawi yokonzekera mu "test run" yogwira ntchito. Imawonetsa nthawi yopangira makina mu "Program Run" yogwira ntchito.

(22) Bwererani ku contour: onetsani nthawi yomwe ikugwiritsidwira ntchito mu "program running" mode. Kusokoneza kwa pulogalamu, kuchoka ndikubwerera ku contour.

(23) Preset point management: tebulo losungira malo aliwonse omwe adakhazikitsidwa.

(24) Origin tebulo: angapo chiyambi matebulo, ntchito kupulumutsa wachibale chiyambi cha workpiece.

(25) 3-D Machining: Motion Control of High Quality Smooth Jerk

(26) Block processing nthawi: 0.5 ms

(27) Kuwongolera ndi sitepe yowonetsera: 0.1 μm

(28) Kuzungulira koyezera: kuyesa kuyesa. Kulipiritsa pamanja kapena kudzidziwikitsa kwa kusokoneza ntchito. Khazikitsani mfundo zokhazikitsidwa pamanja kapena zokha. Chida ndi workpiece akhoza kuyeza basi.

(29) Malipiro olakwika: zolakwika za mzere ndi zosagwirizana ndi mzere, kubweza kumbuyo, kumbuyo kwakuthwa kozungulira kozungulira, cholakwika chakumbuyo, kukulitsa kutentha. static mikangano, kutsetsereka kukangana.

(30) Mawonekedwe a data: RS-232-C/V.24, mpaka 115 kbit/s. Mawonekedwe owonjezera a data a LSV2 protocol, gwiritsani ntchito pulogalamu ya HEIDENHAIN TNCremo kapena TNCremoPlus kuti mugwiritse ntchito TNC kutali kudzera pa data iyi. 2 x Gigabit Efaneti 1000BASE-T mawonekedwe. 5 x USB madoko (1 USB 2.0 doko kutsogolo, 4 USB 3.0 madoko).

(31) Kuzindikira: Zida zodziwira zokha zowunikira mwachangu komanso zosavuta.

(32) CAD wowerenga: amasonyeza muyezo CAD owona mtundu.

Main parameter

| Kanthu | Chigawo | Parameter | |

| Ntchito | worktable diameter | mm | 320 |

| Kuchuluka kopingasa katundu | kg | 150 | |

| Kuchuluka koyimirira | kg | 100 | |

| T-kagawo | mm | 8X10H8 | |

| Mtundu wokonza | Mtunda pakati pa nkhope yozungulira yozungulira ndi nkhope yogwirira ntchito (Max) | mm | 430 |

| Mtunda pakati pa nkhope yozungulira yozungulira ndi nkhope yogwirira ntchito (Min) | mm | 100 | |

| X axis | mm | 450 | |

| Y axis | mm | 320 | |

| Z axis | mm | 330 | |

| B axis | ° | -35°~+ 110° | |

| C axis | ° | 360 ° | |

| Spindle | Mpanda (7 ∶ 24) |

| Mtengo wa BT40 |

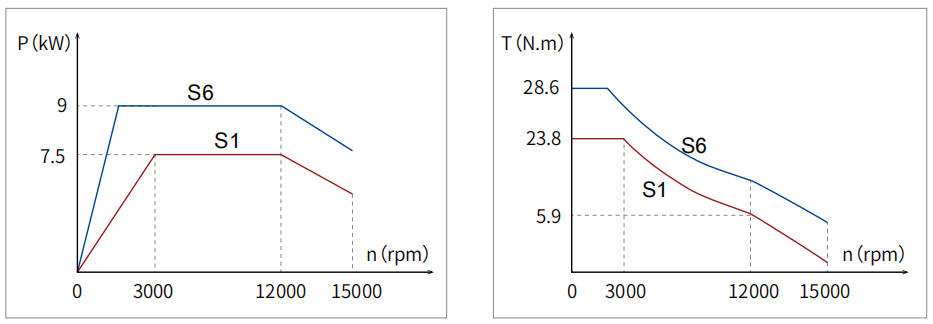

| Kuthamanga kwake | rpm pa | 3000 | |

| Max. liwiro | rpm pa | 15000 | |

| Adavotera torque S1 | Nm | 23.8 | |

| Adavotera Mphamvu S1 | KW | 7.5 | |

|

Mzere | X axis Liwiro lothamanga kwambiri | m/mphindi | 36 |

| Y axis Kuthamanga kwa liwiro | m/mphindi | 36 | |

| Z axis Liwiro lothamanga kwambiri | m/mphindi | 36 | |

| B axis Max. liwiro | rpm pa | 130 | |

| C axis Max. liwiro | rpm pa | 130 | |

| Magazini ya Tool | Mtundu |

| Mtundu wa disc |

| Njira yosankha zida |

| Kusankha zida zapafupi za Bidirectional | |

| Mphamvu | T | 24 | |

| Max. kutalika kwa chida | mm | 150 | |

| Max. kulemera kwa chida | kg | 7 | |

| Max. cutter disc diameter (Chida Chathunthu) | mm | 80 | |

| Maximum cutter disc diameter (Pafupi chida chopanda kanthu) | mm | 150 | |

| Kulondola | Executive muyezo |

| GB/T20957.4(ISO10791-4) |

| X-axis/Y-axis/Z-axis poyikira molondola | mm | 0.008/0.008/0.008 | |

| Kulondola kwa malo a B-axis/C-axis |

| 7 "/ 7" | |

| X-axis/Y-axis/Z-axis kubwereza kubwereza kulondola kwa malo | mm | 0.006/0.006/0.006 | |

| B-axis/C-axis kubwereza kubwereza kulondola kwa malo |

| 5 "/ 5" | |

| Kulemera kwa makina | Kg | 5000 | |

| Mphamvu zonse zamagetsi | KVA | 45 | |

Mndandanda Wokhazikika Wokhazikika

| Ayi. | Dzina |

| 1 | Zigawo zazikuluzikulu (kuphatikiza bedi, chigawo, mbale yojambulidwa, mpando wa slide, mutu) |

| 2 | X, Y, Z 3-axis feed system |

| 3 | Single arm cradle turntable |

| 4 | Spindle yamagetsi BT40 |

| 5 | Dongosolo lowongolera magetsi (kuphatikiza nduna yamagetsi, gawo lamagetsi, gawo la servo, PLC, gulu la opareshoni, chiwonetsero, chogwirizira m'manja, chowongolera magetsi kabati, etc.) |

| 6 | Mulingo wa grating: HEIDENHAIN |

| 7 | Hydraulic system |

| 8 | Pneumatic system |

| 9 | Centralized lubrication system |

| 10 | Chip conveyor, thanki yamadzi, chotolera chip |

| 11 | Mlonda wa njanji |

| 12 | Chida cha makina onse chophimba chophimba |

| 13 | Chipangizo choyezera cha workpiece: HEIDENHAIN TS460 |

|

| Mizere yozungulira HEIDENHAIN |

| 14 | Chida chokhazikitsa chida: HEIDENHAIN NC4 |

| 15 | Kuwongolera molondola kwa ma axis asanu: HEIDENHAIN KKH |

| 16 | Kutengera ndi mfundo imodzi yogwiritsira ntchito pulogalamu ya HPMILL pambuyo pokonza, sungani adilesi yapakompyuta |

| 17 | Spindle thermal elongation compensation function |