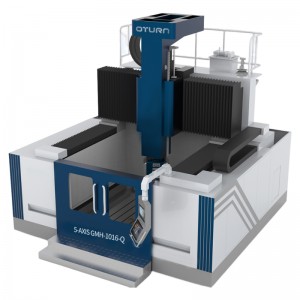

CNC Mbiri Machining Center

CNC Mbiri Machining Center

CNC Drilling Machine

Mawonekedwe a Makina

Bosm DC mndandandaCNC pobowola ndi makina mpheroamagwiritsidwa ntchito kwambiri pobowola mphero ndi kugogoda za workpieces ndi liniya zinthu m'lifupi mwa osiyanasiyana ogwira. Kupyolera mu dzenje ndi akhungu dzenje akhoza mokhomerera pa mbali imodzi zakuthupi ndi gulu zipangizo. The makina processing ndi CNC wolamulira, ntchito ndi yabwino kwambiri. Itha kuzindikira zodzichitira, zolondola kwambiri, zosiyanasiyana komanso kupanga zochuluka.

Kuti tikwaniritse zofunikira za ogwiritsa ntchito osiyanasiyana, kampani yathu yapanga zinthu zosiyanasiyana zomalizidwa.Itha kupangidwanso ndikusinthidwa malinga ndi zosowa zenizeni za ogwiritsa ntchito.

Kapangidwe ka Makina

Chipangizocho chimapangidwa makamaka ndi tebulo la bedi, gantry yam'manja, chishalo cham'manja, kubowola ndi mphero yamagetsi, chipangizo chodzitchinjiriza ndi chitetezo, chipangizo chozungulira chozizira, makina owongolera digito, makina opangira ma hydraulic, magetsi, etc. Makina opangira makina ali ndi malo apamwamba. kulondola ndi kubwereza mobwerezabwereza malo olondola.

1. Bedi & zogwirira ntchito:

Bedi la makina ndi zigawo zamapangidwe azitsulo, ndipo chimango chachikulu chimakonzedwa ndi zigawo zachitsulo. Pambuyo kupsyinjika kwamkati kumachotsedwa ndi chithandizo cha kutentha kwa ukalamba wochita kupanga, chimakhala ndi mphamvu yabwino komanso yosasunthika ndipo palibe mapindikidwe. The worktable amapangidwa ndi kuponyera chitsulo HT250. The worktable angagwiritsidwe ntchitoclamping workpieces. Itha kukhalanso ndi zida za pneumatic, zomwe ndizosavuta komanso zachangu pakuboola zida zogwirira ntchito,. The pazipita kunyamula mphamvu ya worktable ndi 1 tani. Kumtunda kumanzere kwa bedi kumayikidwa molunjika ndi ma ultra-high kunyamula mphamvu zogubuduza zowongolera zowongolera ndi choyikapo cholondola. Gantry motor imayendetsedwa ndi AC servo system ndi rack system mu X direction. Maboti osinthika amagawidwa pansi pa bedi, omwe amatha kusintha mosavuta mlingo wa tebulo la bedi.

2. Kusuntha cantilever:

Chombo chosunthika cha cantilever chokhala ndi chitsulo choponyedwa chimakonzedwa pambuyo pochotsa kupsinjika kwamkati ndi chithandizo cha kutentha kwa ukalamba wochita kupanga, wokhala ndi mphamvu yabwino komanso yosasunthika komanso osasinthika. Mawiri awiri ozungulira omwe ali ndi mphamvu zonyamulira kwambiri amayikidwa kutsogolo ndi kumtunda kwa gantry. Cholozera chozungulira chokhala ndi mphamvu zonyamulira kwambiri, zomangira zolondola kwambiri za mpira ndi injini ya servo zimayikidwa pamwamba kuti mbale yotsetsereka yamutu wamphamvu isunthike ku Y-axis. Mutu wobowola umayikidwa pa mbale ya slide ya mutu wa mphamvu. Kusuntha kwa gantry kumazindikirika ndi kuzungulira kwa wononga mpira moyendetsedwa ndi servo motor kudzera pakulumikizana.

3. Chishalo chosuntha:

Chishalo chosunthika ndi membala wachitsulo. Mawiri awiri ozungulira omwe ali ndi mphamvu yonyamulira kwambiri, seti ya mpira wolondola kwambiri ndi injini ya servo imayikidwa pachishalo chotsetsereka kuyendetsa mutu wobowola kuti usunthire mbali ya z-axis, yomwe imatha kuzindikira mtsogolo mwachangu, ntchito patsogolo, mofulumira chammbuyo ndi kuyimitsa mutu mphamvu. Lili ndi ntchito za automatic chip breaking, kuchotsa chip ndi kuyimitsa.

Special servo spindle motor imagwiritsidwa ntchito pobowola mutu wamagetsi. Spindle yapadera yolondola imayendetsedwa ndi lamba wa synchronous wa mano kuti azindikire kusintha kwa liwiro losasunthika. Chakudyacho chimayendetsedwa ndi servo motor ndi mpira screw.

Y-axis imatha kulumikizidwa ndikuwongoleredwa ndi loop yotsekedwa theka, yomwe imatha kuzindikira kutanthauzira kozungulira komanso kozungulira. Kumapeto kwakukulu kwa shaft ndi er taper hole clamping kubowola kapena mphero, molunjika kwambiri, kudula kwambiri, kusintha kwa chipangizo cha pneumatic, chosankha ndi magazini ya chida chamtundu wa chipewa, magazini ya zida zisanu ndi zitatu, kusintha kwa zida ndikosavuta, digiri yapamwamba ya automation. ya manual processing.

5. Chida chodzitchinjiriza chokha ndi chida choteteza:

Makinawa ali ndi zida zodzitchinjiriza zokha, zomwe zimatha kudzipangira mafuta awiriawiri oyenda monga njanji yowongolera, zowongolera zotsogola ndi rack. X-axis ndi Y-axis yamakina ili ndi chivundikiro choteteza chopanda fumbi, ndipo chotchinga chopanda madzi chimayikidwa mozungulira chogwirira ntchito.

6. KND Control System:

6.1. Ndi chip breaking function, chip breaking time ndi chip breaking cycle zitha kukhazikitsidwa pamakina amunthu.

6.2. Ndintchito yokweza zida, chida chokweza kutalika chikhoza kukhazikitsidwa pa mawonekedwe a makina a munthu. Pobowola mpaka kutalika uku, kubowolako kumakwezedwa mwachangu pamwamba pa chogwiriracho, ndiye kuti chip chimaponyedwa, kenako ndikuthamangira pobowola ndikusinthidwa kukhala ntchito.

6.3. Bokosi lapakati loyang'anira ntchito ndi gawo lakumanja lili ndi dongosolo la CNC, mawonekedwe a USB ndi chophimba cha LCD. Pofuna kuwongolera mapulogalamu, kusungirako, kuwonetsera ndi kulankhulana, mawonekedwe ogwiritsira ntchito ali ndi ntchito za kukambirana kwa makina a munthu, kubwezera zolakwika ndi alamu yokha.

6.4. Zidazi zimakhala ndi ntchito yowoneratu ndikuwunikanso malo a dzenje musanapange makina, kotero kuti ntchitoyi ndi yabwino kwambiri.

Kufotokozera

| Chitsanzo | BOSM-DC60050 | |

| Max. workpiece kukula | Utali × m'lifupi (mm) | 2600 × 500 |

| Mutu wamphamvu wakubowola Ram | Kuchuluka (chidutswa) | 1 |

| Spindle taper dzenje | Mtengo wa BT40 | |

| Kubowola m'mimba mwake (mm) | Φ2-Φ26 | |

| Liwiro la spindle (R / min) | 30-3000 | |

| Mphamvu ya spindle (kw) | 15 | |

| Mtunda pakati pa mphuno ya spindle ndi tebulo logwirira ntchito (mm) | 150-650 mm | |

| X-axis (ulendo wotsatira) | Kukwapula kwakukulu (mm) | 500 |

| Kuthamanga kwa X-axis (M / min) | 0~9 pa | |

| X-axis servo motor mphamvu (kw) | 2.4*1 | |

| Y-axis (column longitudinal movement) | Kukwapula kwakukulu (mm) | 2600 |

| Kuthamanga kwa Y-axis (M / min) | 0~9 pa | |

| Mphamvu ya y-axis servo motor (kw) | 2.4*1 | |

| Z axis (Kuyenda kwa nkhokwe yoyimirira) | Kukwapula kwakukulu (mm) | 500 |

| Kuthamanga kwa Z axis (M / min) | 0~8 pa | |

| Z-axis servo motor mphamvu (kw) | 1 × 2.4 ndi brake | |

| Kukula kwa makina | Utali × m'lifupi × kutalika (mm) | 5400×2180×2800 |

| Kuyika kulondola | X/Y/Z | ± 0.05/300mm |

| Kuyika mobwerezabwereza kulondola | X/Y/Z | ± 0.025/300mm |

| Kulemera kwakukulu (t) | 4.5 | |

Kuyang'anira Ubwino

Makina aliwonse amawunikidwa ndi laser interferometer yochokera ku kampani ya United Kingdom RENISHAW, yomwe imayang'ana molondola ndikubwezera zolakwika za phula, kubweza kumbuyo, kulondola kwa malo, komanso kutsimikizika kobwerezabwereza kuwonetsetsa kuti makinawo ali osunthika, osasunthika komanso olondola. . Mpira bala mayeso Makina aliwonse amagwiritsa ntchito choyesera mpira kuchokera ku kampani yaku Britain ya RENISHAW kukonza kulondola kwa bwalo lolondola ndi makina olondola a geometric, ndikuchita zoyeserera zodulira zozungulira nthawi imodzi kuti zitsimikizire kulondola kwa makina a 3D ndi kulondola kwa bwalo.

Malo ogwiritsira ntchito chida cha makina

1.1 Zida zofunikira zachilengedwe

Kusunga mulingo wokhazikika wa kutentha kozungulira ndikofunikira kwambiri pakukonza makina.

(1) Kutentha komwe kulipo ndi -10 ℃ ~ 35 ℃. Kutentha kozungulira 20 ℃, chinyezi chiyenera kukhala 40 ~ 75%.

(2) Pofuna kusunga kulondola kwachida cha makina mkati mwazomwe zatchulidwa, kutentha kwabwino kwambiri kumafunika kukhala 15 ° C mpaka 25 ° C ndi kusiyana kwa kutentha.

Siyenera kupitirira ± 2 ℃ / 24h.

1.2 Mphamvu yamagetsi: 3-gawo, 380V, kusinthasintha kwamagetsi mkati mwa ± 10%, ma frequency amagetsi: 50HZ.

1.3 Ngati voteji pamalo ogwiritsira ntchito ndi osakhazikika, chida cha makina chiyenera kukhala ndi magetsi oyendetsedwa bwino kuti atsimikizire kuti makinawo akugwira ntchito bwino.

1.4. Chida cha makina chiyenera kukhala ndi maziko odalirika: waya woyakirapo ndi waya wamkuwa, waya wosachepera 10mm², ndipo kukana kwapansi kumakhala kosakwana 4 ohms.

1.5 Kuti zitsimikizire kuti zida zogwirira ntchito zikuyenda bwino, ngati mpweya woponderezedwa wa gwero la mpweya ukulephera kukwaniritsa zofunikira za gwero la mpweya, zida zoyeretsera mpweya (dehumidification, degreasing, kusefa) ziyenera kuwonjezeredwa pamaso pa mpweya wa makina.

1.6. Zidazi ziyenera kusungidwa kutali ndi kuwala kwa dzuwa, kugwedezeka ndi kutentha, komanso kutali ndi majenereta othamanga kwambiri, makina opangira magetsi, ndi zina zotero, kuti apewe kulephera kupanga makina kapena kutaya makina olondola.

Pamaso & Pambuyo Service

1) Pamaso pa Service

Kupyolera mu phunziro pempho ndi mfundo zofunika kwa makasitomala ndiye ndemanga kwa akatswiri athu, Bossman Technical gulu ndi udindo kulankhulana luso ndi makasitomala ndi mapangidwe mayankho, kuthandiza kasitomala kusankha njira yoyenera Machining ndi makina oyenera.

2) Pambuyo pa Service

A.Makina omwe ali ndi chitsimikizo cha chaka chimodzi ndikulipirira kukonza kwa moyo wonse.

B.Panthawi yachitsimikizo cha chaka chimodzi makinawo atafika padoko, BOSSMAN idzapereka chithandizo chaulere komanso chanthawi yake pazolakwa zosiyanasiyana zomwe sizinapangidwe ndi anthu pamakina, ndikusintha munthawi yake mitundu yonse ya zida zowonongeka zomwe sizinapangidwe ndi anthu. cha malipiro . Zolephera zomwe zimachitika panthawi ya chitsimikizo zidzakonzedwa pamitengo yoyenera.

Thandizo la C.Technical mu maola 24 pa intaneti, TM, Skype, E-mail, kuthetsa mafunso achibale mu nthawi. ngati sizingathetsedwe, BOSSMAN ikonza nthawi yomweyo kuti mainjiniya atagulitsa azifika pamalowo kuti akonzedwe, wogula amayenera kulipira VISA, matikiti oyendetsa ndege ndi malo ogona.

Tsamba la Makasitomala