Mndandanda wa CTB wamagulu asanu ozungulira Vertical Machining Center

Mawonekedwe

Makina oyamba

1.Kukonza makina osakwera mtengo kwa asanu olamulira munthawi imodzi

Kapangidwe kamtundu wa C-Class, wokhala ndi makina opangira magetsi odzipangira okha, komanso tebulo loyendetsa molunjika, makina apamwamba kwambiri a CNC, amawonetsa bwino kwambiri. Imathandizira ma spindle amagetsi osankhidwa amitundu yosiyanasiyana komanso kutembenuza ndi kugaya matebulo ozungulira.

2.Direct-drive turntable

Chosinthira chodzipangira chodzipangira chokha chimatenga injini yolondola kwambiri ya torque, zero transmission gap, osavala, ndipo imakhala ndi encoder yolondola kwambiri.

High-mapeto CNC dongosolo amakwaniritsa mkulu wamphamvu mwatsatanetsatane kulamulira.

Swivel turntable, ma axis asanu olumikizira kulumikizana, kulemera kwakukulu kwa workpiece 150kg-3000kg, ndi kukonza kolakwika kungatheke. B axis ili ndi chothandizira chothandizira chokhala ndi kukhazikika kwamphamvu.

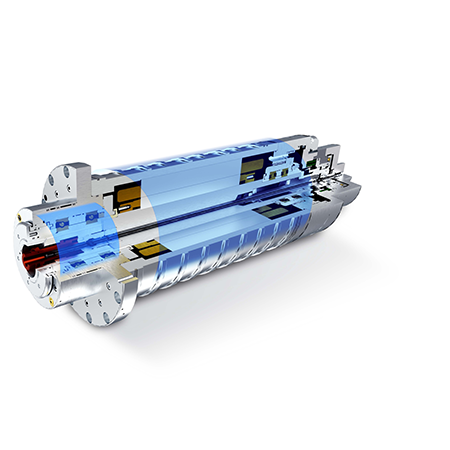

3.HSK mndandanda wamagetsi ozungulira

Spindle yamagetsi imagwiritsa ntchito injini yamkati ya asynchronous, yolondola kwambiri ya ceramic, sensa ya vibration, sensor ya kutentha ndi zida zoziziritsa zamkati ndizosankha.

4. Dongosolo lopaka mafuta limatenga mafuta opaka nthawi yayitali;

5. Dongosolo loziziritsa limagwiritsa ntchito mpope woziziritsa wothamanga kwambiri kuti ukwaniritse zosowa zoziziritsa za zida za spindle ndi zogwirira ntchito. Sing'anga yozizira imatsimikiziridwa molingana ndi mikhalidwe yeniyeni ya zogwirira ntchito za wogwiritsa ntchito;

6. Makina ochotsa tchipisi amatengera makina ochotsa tchipisi (mzere wakumbuyo)

7. Chida cha ATC chosinthira cam box cha magazini ya chida chimakhala ndi kuyang'anira basi kwa mafuta opaka mafuta kuti achepetse kuwonongeka kwakukulu kwa zida zomwe zimayambitsidwa ndi mawanga akhungu pakukonza pamanja;

8. Makina opangira zida amaika patsogolo kukonza.Mapangidwe a zigawo zazikulu za chida ichi cha makina amachokera pa mfundo yotseguka, yomwe ili yabwino kuyika, kukonzanso ndi kukonza, ndipo mazenera okonza amasiyidwa m'madera ena;

9. Chida cha makina ndi chosavuta kugwiritsa ntchito, kugwira ntchito ndi kusamalira komanso kukhala ndi maonekedwe okongola.Kugwiritsa ntchito ndi kukonza zida zamakina sikungawononge thanzi la munthu kapena kuipitsa chilengedwe;

Mfundo Zaukadaulo

| Kanthu | Chigawo | V5-320B | V5-630B | V5-1000A | ||||

| Table | ||||||||

| Diameter | mm | 320 | 630 | 1000 | ||||

| Max. katundu yopingasa | kg | 150 | 500 | 3000 | ||||

| Max. katundu woima | 100 | 300 | 2000 | |||||

| T-slots (nambala X m'lifupi) | Ayi. X mm | 8X10H8 | 8x14H8 | 5x18 pa | ||||

| Makina osiyanasiyana | ||||||||

| Kutalikirana ndi mphuno ya spindle | Kuchuluka (mm) | 430 | 550 | 1080 | ||||

| pa tebulo pamwamba | Mphindi (mm) | 100 | 150 | 180 | ||||

| X-axis | mim | 450 | 600 | 1150 | ||||

| Y-axis | mm | 320 | 450 | 1300 | ||||

| Z-axis | mm | 330 | 400 | 900 | ||||

| B-axis | . | -35 ~ +110 | -35 ~ +110 | -150 ~ +130 | ||||

| C-axis | . | ndi x360 | ndi x360 | ndi x360 | ||||

| Spindle | ||||||||

| Chogwirizira |

| Mtengo wa BT30 | Mtengo wa HSKE40 | Mtengo wa BT40 | Mtengo wa HSKA63 | Mtengo wa BT50 | Mtengo wa HSKA100 | |

| Kokani chingwe |

| Chithunzi cha MAS403 BT30-I |

| Chithunzi cha MAS403 BT40-I |

| Mtengo wa MAS403 BT50-I |

| |

| Kuthamanga kwake | rpm pa | 12000 | 17500 | 1800 | 2000 | 1500 | ||

| Max. liwiro | 24000 | 32000 | 12000 | 18000 | 10000 | |||

| Makina opangira ma spindle (S1 / S6) | Nm | 12/15.5 | 6/8.2 | 69/98 | 72/88 | 191/236 | ||

| Mphamvu ya spindle yoyendetsedwa ndi injini (S1 / S6) | kW | 15/19.5 | 11/15 | 13/18.5 | 15/18.5 | 30/37 | ||

| Coordinate axis | ||||||||

| Kuyenda mwachangu | X-axis |

m/mphindi | 36 | 36 | 25 | |||

| Y-axis | 36 | 36 | 25 | |||||

| Z-axis | 36 | 36 | 25 | |||||

| Max. liwiro | B-axis | rpm pa | 100 |

| 15 | |||

| C-axis | 80 |

| ||||||

| 130 | 80 | 30 | ||||||

| Makina osinthira zida | ||||||||

| Mtundu | Mtundu wa disk | Mtundu wa disk | Horizontal unyolo mtundu servo automatic chida chosinthira | |||||

| Kusankha zida | Bidirectional proximity principle

| Bidirectional proximity principle

| Bidirectional proximity principle | |||||

| Mphamvu | T | 24/30 | 24 | 30 | ||||

| Max. kutalika kwa chida | mm | 200 | 300 | 400 | ||||

| Ma chida kulemera | kg | 3.5 | 8 | 20 | ||||

| Max disk diameter | Zodzaza | mm | 65 | 80 | 125 | |||

|

| Malo oyandikana alibe kanthu | 125 | 150 | 180 | ||||

| Kulondola | ||||||||

| Kukhazikitsa Miyezo | GB/T 20957 | GB/T 20957 | GB/T 20957 | |||||

| Kuyika kulondola | X/Y/Z olamulira | mm

| 0.006 | 0.007 | 0.08 | |||

|

| B/C axis | “ | 6 | 6 | 8 | |||

| Kubwerezabwereza | X/Y/Z olamulira | mm | 0.004 | 0.005 | 0.006 | |||

| B/C axis | “ | 4 | 4 | 6 | ||||

| Kulemera | kg | 4000 | 6500 | 33000 | ||||

| Mphamvu | KVA | 45 | 45 | 80 | ||||

| Makulidwe onse (LXWXH) | mm | 3460 X 3000X 2335 | 4000 X 4000X 3200 | 7420X4800X4800 | ||||

Processing Cases

Zigawo Zamafoni a M'manja

Zigawo Zomangamanga

Zokongoletsera

Zokakamiza

Bridge Plating

Mavavu Matupi