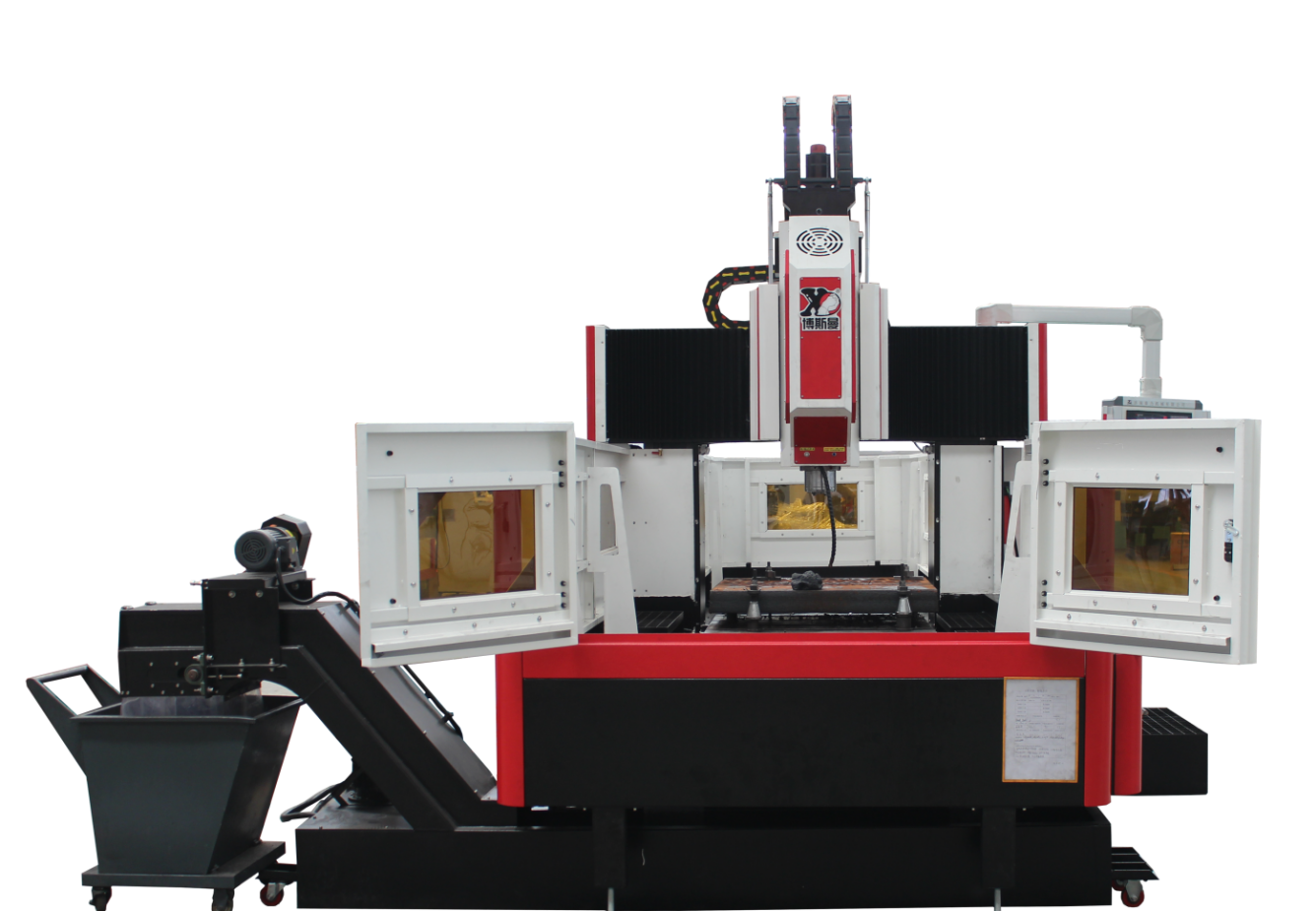

Fixed Beam CNC Drilling and Milling Machine

CNC Drilling & Milling Machine

Ntchito Yamakina Ndi Kufotokozera Kwamawonekedwe

1) CNC gantry kubowola ndi mphero makina ndi makina machining kuti kuphatikiza umisiri zapamwamba monga makina, magetsi, ndi hayidiroliki. Amagwiritsidwa ntchito kwambiri pokonza nkhungu, ma flanges, mavavu, zigawo zamapangidwe ect. Amagwiritsidwa ntchito roughing ndi kutsiriza mbali zovuta monga mbale zosiyanasiyana, mabokosi, mafelemu, nkhungu etc. mu makampani kupanga makina. Chida ichi chimatha kuzindikira mopingasa (Y-axis) ndikuyenda molunjika (Z-axis) ya mutu wopindika wamphero ndi tebulo Kulumikizana kwa ma axis atatu akuyenda kotalika (X axis). Mipikisano ndondomeko monga mphero, wotopetsa, kubowola, kugogoda okhwima, reaming, ndi countersinking akhoza kuchitidwa. Makina onse amatengera mawonekedwe a gantry frame, ndi kukhazikika kwakukulu komanso kusungidwa bwino. Ndilo kusankha koyamba kwa ogwiritsa ntchito.

2) Kukonzekera kwathunthu kwa makina

(1) Mtundu wokhazikika wa mtengo wa gantry umakhazikitsidwa, bedi limakhazikika, ndipo mizati iwiri ndi bedi zimalumikizidwa ndi mabawuti. The worktable imayenda mu X axis pabedi, mutu wamutu umasunthira kumbali ya Z pa chishalo, ndipo chishalo ndi mutu zimasunthira ku Y malangizo pamtengo.

(2) Zigawo zazikuluzikulu za chida cha makina: bedi, mzati, mtanda, chishalo, ndi mutu zonse ndi zida zachitsulo zopangira mphamvu zambiri. Zigawo zazikuluzikuluzi zimakongoletsedwa ndi mapulogalamu apakompyuta a 3D, okhala ndi nthiti zoyenera komanso njira zochizira kutentha kwathunthu kuti athetse kupsinjika kotsalira. , Kuonetsetsa kuti makina onse ali ndi mphamvu zokwanira, kukhazikika komanso kukhazikika kwakukulu, kudula kugwedezeka kwamphamvu.

3) Bed-Workbench

(1) Bedi limapangidwa ndi chitsulo champhamvu kwambiri cha HT250, pogwiritsa ntchito makina opangira makompyuta atatu-dimensional mothandizidwa ndi kukhathamiritsa, nthiti zimakonzedwa moyenera, ndipo kulimba kwake ndi mphamvu zake zimasinthidwa.

(2) Gulu la X-axis njanji imatengera zilozera zolemetsa zomwe zimatumizidwa kunja, zokhala ndi mikangano yocheperako komanso yosasunthika, kunjenjemera kwapatebulo, kugwedezeka kotsika kwambiri, kuthamanga kwambiri osakwawa, malo olondola kwambiri, komanso magwiridwe antchito abwino kwambiri a servo drive. : nthawi yomweyo, katundu mphamvu ndi lalikulu, ndi kudula kugwedera kukana ndi zabwino. .

(3) X-axis drive-motor ya servo imalumikizidwa ndi wononga mpira kudzera pa chodulira, chomwe chimayendetsa chogwirira ntchito kuti chisunthire mmbuyo ndi mtsogolo pakama kuti muzindikire kayendedwe ka chakudya cha X ndikuwongolerera wononga kuti muwongolere. Kuuma.

4) Mwala

(1) Mtanda ndi mzati zimaphatikizidwa mu mawonekedwe a gantry frame, pogwiritsa ntchito chitsulo chachitsulo champhamvu kwambiri cha HT250, nthitizo zimakonzedwa moyenera, ndipo zimakhala ndi kupindika kokwanira ndi kugwedezeka.

(2) Gulu la kalozera wamtengo litengera kalozera wolemera.

(3) Y-axis drive-motor ya servo imalumikizidwa mwachindunji ndi wononga mpira polumikizana, ndipo zomangira za mpira zimayendetsa chishalo kuti zisunthe kumanzere ndi kumanja pamtengo kuti zizindikire kayendedwe ka chakudya cha Y-axis.

5) Mutu wamutu

(1) Mutuwo umagwiritsa ntchito kalozera wodzigudubuza wolemera kwambiri, womwe umakhala wokhazikika kwambiri, wokhazikika bwino, komanso kukhazikika kwachangu.

(2) Z-axis drive-motor ya servo imalumikizidwa mwachindunji ndi wononga mpira polumikizana, ndipo zomangira za mpira zimayendetsa mutu kuti zisunthe mmwamba ndi pansi pa chishalo kuti muzindikire chakudya cha Z-axis. Galimoto ya Z-axis ili ndi ntchito yoboola yokha. Kukanika mphamvu, shaft yamoto imagwiridwa mwamphamvu kuti isazungulire.

(3) Gulu la spindle limatenga spindle yoziziritsa yamkati yaku Taiwan Jianchun yolondola kwambiri komanso magwiridwe antchito apamwamba. Tsinde lalikulu limagwira mpeni ndi kasupe wa gulugufe patsinde lalikulu ndi mphamvu yamphamvu yomwe ikugwira ntchito pa kukoka msomali wa chogwirira cha chida kudzera pamakina anayi a broach, ndipo chida chotayirira chimatenga njira ya pneumatic.

6) Pneumatic system

Amagwiritsidwa ntchito kumasula chida cha spindle.

7) Chitetezo cha makina

Njanji ya bedi (X axis) imatenga chivundikiro chachitetezo cha telescopic chosapanga dzimbiri;

Chiwongolero chamtengo (Y axis) chimatengera chitetezo cha chiwalo chosinthika.

8) Kupaka mafuta

(1) X, Y, Z mayendedwe atatu a axis onse apaka mafuta.

(2) X, Y, Z mayendedwe a ma axis atatu onse amapaka mafuta.

(3) X, Y, Z zomata za mipira yozungulira zitatu zonse zimapaka mafuta.

9) CNC dongosolo

The CNC dongosolo ndi muyezo okonzeka ndi Beijing Kaiendi dongosolo ulamuliro ndi galimoto, ndi ntchito wathunthu ndi ntchito yosavuta; mawonekedwe olumikizirana a RS-232, socket ya USB ndi mapulogalamu ofananira.

Sefa System

Makinawa ali ndi makina apakati osefera madzi, omwe amatha kusefa bwino zonyansa muzoziziritsa kukhosi. Dongosolo la kutsitsi lamkati lamadzi limatha kuletsa zikhomo zachitsulo kuti zisamangidwe pazida panthawi yokonza, kuchepetsa kuvala kwa zida, kukulitsa moyo wa zida, ndikuwongolera kumaliza kwa workpiece. Pini yotulutsa madzi yothamanga kwambiri imatha kuteteza pamwamba pa chogwirira ntchito, kuteteza cholumikizira chothamanga kwambiri, kuteteza zonyansa kuti zisatseke cholumikizira chozungulira, ndikuwongolera magwiridwe antchito onse ndikuwongolera magwiridwe antchito. (Zindikirani chithunzi ndi chithunzi cha mawonekedwe a fyuluta)

Kufotokozera

| Chitsanzo | BOSM-DPH2016 | BOSM-DPH2022 | BOSM-DPH2625 | BOSM-DPH4026 | |

| Kukula kwa ntchito (mm) | 2000 * 1600 | 2000*2000 | 2500*2000 | 4000 * 2200 | |

| Max.loading(Kg) | 7000 | 7000 | 7000 | 7000 | |

| T Slot(mm) | 8*22 | 8*22 | 8*22 | 8*22 | |

| Kuyenda kwakukulu kwa tebulo-X axis(mm) | 2200 | 2200 | 2600 | 4000 | |

| Kuyenda kwakukulu kwa tebulo-Y axis(mm) | 1600 | 2200 | 2500 | 2600 | |

| Spindle maximum stroke-Z axis(mm) | 600 | 600 | 600 | 600/1000 | |

| Mtunda kuchokera kumapeto kwa spindle kupita ku tebulo logwirira ntchito (mm) | Kuchuluka | 800 | 800 | 800 | 800 |

| Zochepa | 200 | 200 | 200 | 200 | |

| Mpanda (7:24) | Mtengo wa BT50 | Mtengo wa BT50 | Mtengo wa BT50 | Mtengo wa BT50 | |

| Liwiro la spindle(r/min) | 30 ~ 3000/60 ~ 6000 | 30 ~ 3000/60 ~ 6000 | 30 ~ 3000/60 ~ 6000 | 30 ~ 3000/60 ~ 6000 | |

| Spindle motor power (Kw) | 22 | 22 | 22 | 22 | |

| Max. Kubowola (mm) | φ90 | φ90 | φ90 | φ90 | |

| Kugunda kwakukulu (mm) | M36 | M36 | M36 | M36 | |

| Kudula liwiro la chakudya | 1-4000 | 1-4000 | 1-4000 | 1-4000 | |

| Kuyenda mwachangu (m/mphindi) | 2008/8/8 | 2008/8/8 | 2008/8/8 | 2008/8/8 | |

| Kukhazikitsa miyezo ya dziko GB/T18400.4(m/min) | ± 0.01/1000mm | ± 0.01/1000mm | ± 0.01/1000mm | ± 0.01/1000mm | |

| Kulemera (T) | 16.5 | 21 | 24 | 40 | |

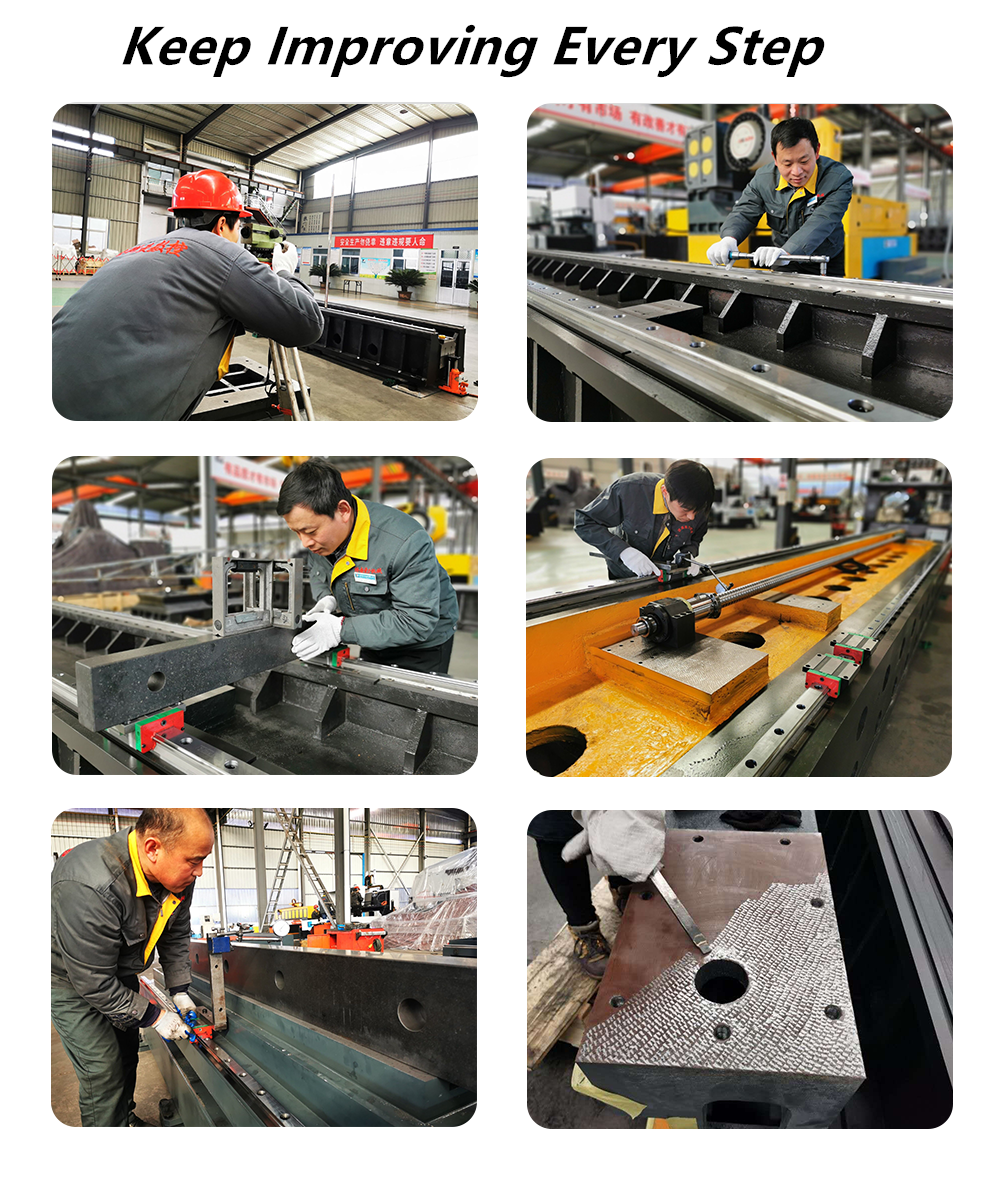

Kuyang'anira Ubwino

Makina aliwonse a Bosman amayesedwa ndi laser interferometer yochokera ku kampani ya United Kingdom RENISHAW, yomwe imayang'ana molondola ndikubwezera zolakwika za phula, kubweza, kulondola kwa malo, komanso kukhazikika kobwerezabwereza kuwonetsetsa kuti makinawo ndi amphamvu, osasunthika komanso olondola. . Mpira bala mayeso Makina aliwonse amagwiritsa ntchito choyesera mpira kuchokera ku kampani yaku Britain ya RENISHAW kukonza kulondola kwa bwalo lolondola ndi makina olondola a geometric, ndikuchita zoyeserera zodulira zozungulira nthawi imodzi kuti zitsimikizire kulondola kwa makina a 3D ndi kulondola kwa bwalo.

Malo ogwiritsira ntchito chida cha makina

1.1 Zida zofunikira zachilengedwe

Kusunga mulingo wokhazikika wa kutentha kozungulira ndikofunikira kwambiri pakukonza makina.

(1) Kupezeka kozungulira kutentha ndi -10℃ ~35 ℃. Pamene kutentha kozungulira ndi 20℃, chinyezi chiyenera kukhala 40~75%.

(2) Kuti tisunge kulondola kwachida cha makina mkati mwazomwe zafotokozedwa, kutentha koyenera kozungulira kumafunika kukhala 15.° C ku 25° C ndi kusiyana kwa kutentha

Isapitirire± 2 ℃/ 24h.

1.2 Magetsi amagetsi: 3-gawo, 380V, kusinthasintha kwamagetsi mkati± 10%, pafupipafupi mphamvu: 50HZ.

1.3 Ngati voteji pamalo ogwiritsira ntchito ndi osakhazikika, chida cha makina chiyenera kukhala ndi magetsi oyendetsedwa bwino kuti atsimikizire kuti makinawo akugwira ntchito bwino.

1.4. Chida cha makina chiyenera kukhala ndi maziko odalirika: waya wokhazikika ndi waya wamkuwa, waya wa waya sayenera kuchepera 10mm.², ndipo kukana kwapansi kumakhala kosakwana 4 ohms.

1.5 Kuti zitsimikizire kuti zida zogwirira ntchito zikuyenda bwino, ngati mpweya woponderezedwa wa gwero la mpweya ukulephera kukwaniritsa zofunikira za gwero la mpweya, zida zoyeretsera mpweya (dehumidification, degreasing, kusefa) ziyenera kuwonjezeredwa pamaso pa mpweya wa makina.

1.6. Zidazi ziyenera kusungidwa kutali ndi kuwala kwa dzuwa, kugwedezeka ndi kutentha, komanso kutali ndi majenereta othamanga kwambiri, makina opangira magetsi, ndi zina zotero, kuti apewe kulephera kupanga makina kapena kutaya makina olondola.

Pamaso & Pambuyo Service

1) Pamaso pa Service

Kupyolera mu phunziro pempho ndi mfundo zofunika kwa makasitomala ndiye ndemanga kwa akatswiri athu, Bossman Technical gulu ndi udindo kulankhulana luso ndi makasitomala ndi mapangidwe mayankho, kuthandiza kasitomala kusankha njira yoyenera Machining ndi makina oyenera.

2) Pambuyo pa Service

A.Makina omwe ali ndi chitsimikizo cha chaka chimodzi ndikulipirira kukonza kwa moyo wonse.

B.Panthawi yachitsimikizo cha chaka chimodzi makinawo atafika padoko, BOSSMAN idzapereka chithandizo chaulere komanso chanthawi yake pazolakwa zosiyanasiyana zomwe sizinapangidwe ndi anthu pamakina, ndikusintha munthawi yake mitundu yonse ya zida zowonongeka zomwe sizinapangidwe ndi anthu. cha malipiro . Zolephera zomwe zimachitika panthawi ya chitsimikizo zidzakonzedwa pamitengo yoyenera.

Thandizo la C.Technical mu maola 24 pa intaneti, TM, Skype, E-mail, kuthetsa mafunso achibale mu nthawi. ngati sizingathetsedwe, BOSSMAN ikonza nthawi yomweyo kuti mainjiniya atagulitsa azifika pamalowo kuti akonzedwe, wogula amayenera kulipira VISA, matikiti oyendetsa ndege ndi malo ogona.

Tsamba la Makasitomala