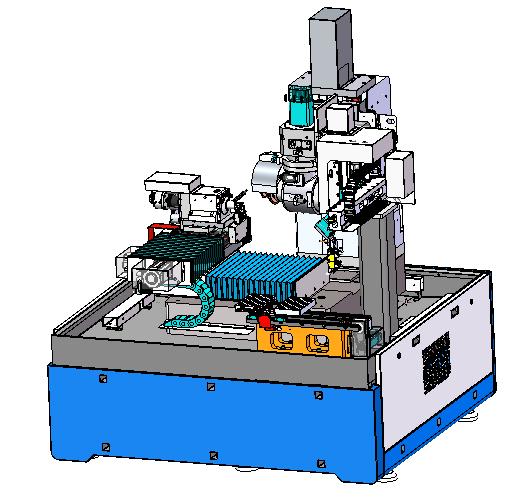

Makina Opera a GM5X-E 5-axis CNC

Main kapangidwe chithunzi cha makina

Kuchuluka kwa ntchito

Makinawa amatulutsa chodulira mphero ndi kubowola, oyenera kukonza aloyi yolimba ndi zida zachitsulo zothamanga kwambiri.

Kupanga zida ndi kuzungulira regrinding

Standard end mphero wodula: slotting, processing fosholo kumbuyo, Front ngodya akupera, Pansi m'mphepete akupera, Digitalize, Regrinding.

Kubowola Standard: kagawo, Kuchepetsa awiri akunja, Front ngodya akupera, digitoize, Regrinding.

1. Mafotokozedwe aukadaulo

| № | Zamkatimu | Chofunikira | Nambala | Chigawo |

| 1.1 | Miyeso ya Workpiece | |||

| 1.1.1 | Kutalika kwa clamping | ≤ | 300 | mm |

| 1.1.2 | Kutalika kwa clamping | pakati | 2-20 | mm |

| 1.1.3 | Utali wopera | ≤ | 180 | mm |

| 1.1.4 | M'mimba mwake akupera | pakati | 2-12 | mm |

| 1.2 | Kugaya Spindle | |||

| 1.2.1 | Mtundu wagalimoto | Zolondola | Direct drive | - |

| 1.2.2 | Mphamvu | oveteredwa mphamvu | 7.1 | kW |

| 1.2.3 | Kuziziritsa | Zolondola | Mafuta utakhazikika | - |

| 1.2.4 | Kuwongolera liwiro la gudumu lopera | Zolondola | Popanda sitepe-liwiro | - |

| 1.2.5 | Liwiro | pakati | 0-10000 | rpm pa |

| 1.2.6 | Chiwerengero cha mitu yopera zitsulo | Zolondola | 2 | ma PC |

| 1.3 | gudumu lopera | |||

| 1.3.1 | Diameter | ≤ | 150 | mm |

| 1.3.2 | Chiwerengero chachikulu cha mawilo opera pa spindle iliyonse | ≤ | 4 | ma PC |

| 1.3.3 | Mawilo akupera spindle diameter | Zolondola | 25 | mm |

| 1.3.4 | Pulogalamu yoyendetsedwa ndi zoziziritsa kukhosi | Zolondola | Inde | - |

| 1.3.5 | Chiwerengero cha nozzles ozizira | ≥ | 3 | ma PC |

| 1.4 | Workpiece clamping system | |||

| 1.4.1 | Clamping system | Zolondola | Hydraulic, automatic | - |

| 1.4.2 | Kuwombera kolala | Zolondola | SCHAUBLIN W20 | - |

| 1.4.3 | Mtundu wagalimoto | Zolondola | Direct drive | - |

| 1.5 | Magawo a axis | |||

| 1.5.1 | Mtundu | Zolondola | mzere | - |

| 1.5.2 | Ulendo wa X-axis | ≤ | 340 | mm |

| 1.5.3 | Ulendo wa Z-axis | ≤ | 335 | mm |

| 1.5.4 | Ulendo wa Y-axis | ≤ | 170 | mm |

| 1.5.5 | XYZ axis resolution | Zolondola | 0.0001 | mm |

| 1.5.6 | XYZ liwiro la axis | ≤ | 15 | m/mphindi |

| 1.5.7 | Ulendo wa A-xis | ≤ | 360 | digiri |

| 1.5.8 | Kusintha kwa A-axis | Zolondola | 0.0001 | digiri |

| 1.5.9 | Liwiro la A-xis | ≤ | 500 | rpm pa |

| 1.5.10 | B-axis kuyenda | ± | 180 | madigiri |

| 1.5.11 | B-axis liwiro | ≤ | 20 | rpm pa |

| 1.6 | Loading ndi kutsitsa dongosolo | |||

| 1.6.1 | Loading ndi kutsitsa dongosolo | Zolondola | Truss mtundu wa robotic mkono | - |

| 1.6.2 | Chiwerengero cha trays | Zolondola | 2 | ma PC |

| 1.6.3 | Kutsegula ndi kutsitsa kokha m'mimba mwake | Pakati | 3-16 | mm |

| 1.6.4 | Kutsegula ndi kutsitsa kutalika kwa chidutswa cha ntchito | ≤ | 90 | mm |

| 1.6.5 | Chiwerengero chachikulu cha workpieces | ≤ | 300 | ma PC |

| 1.6.6 | Mapulogalamu | Zolondola | Inde | - |

| 1.7 | Zigawo zina | |||

| 1.7.1 | Kutha kuzindikira zida zogwirira ntchito pazida zamakina | Zolondola | Inde | - |

| 1.7.2 | Centralized automatic lubrication system | Zolondola | Inde |

|

| 1.7.3 | Tricolor chizindikiro nyali | Zolondola | Inde | - |

| 1.8 | Zosankha | |||

| 1.8.1 | Zida zolekanitsa nkhungu zamafuta | Zolondola | Zosankha | - |

| 1.9 | Kulamulira | |||

| 1.9.1 | Dongosolo lowongolera | Zolondola | Newcon | - |

| 1.9.2 | Operation Panel | Zolondola | Zenera logwira | - |

| 1.9.3 | Digital control axis | Zolondola | Inde | - |

| 1.9.4 | Chiwonetsero chamtundu | Zolondola | Inde | - |

| 1.9.5 | Kukula Kwawonetsero | Zolondola | 19 | inchi |

| 1.10 | Chida akupera pulogalamu module | |||

| 1.10.1 | Zodula mphero zosavuta | Zolondola | Inde | - |

| 1.10.2 | Zoyeserera zosavuta | Zolondola | Inde | - |

| 1.10.3 | Mufufuze zodziwikiratu mode | Zolondola | Inde | - |

| 1.11 | Zida zamagetsi magawo | |||

| 1.11.1 | Voteji | Zolondola | 380±10% | V |

| 1.11.2 | pafupipafupi | Zolondola | 50±10% | Hz |

| 1.11.3 | Mphamvu | ≤ | 25 | KW |

| 1.12 | Makulidwe | |||

| 1.12.1 | Utali | ≤ | 1 820 | mm |

| 1.12.2 | M'lifupi | ≤ | 2 650 | mm |

| 1.12.3 | Kutalika | ≤ | 2 300 | mm |

| 1.12.4 | Ubwino | ≤ | 4 300 | kg |

2. Mndandanda wa kasinthidwe wamba

| № | Zamkatimu | Chitsanzo | Mtundu | Nambala | ||

| 2.1 | Chida cha makina | |||||

| 2.1.1 | Kusintha kwa X-axis | |||||

| 2.1.1.1 | - Ndodo ya screw | Zosinthidwa mwamakonda | NSK | 1 ma PC | ||

| 2.1.1.2 | -Njanji | 1×MR25-A2-760-20-20-G2-V2+BRK+SOSPL | Malingaliro a kampani SCHNEEBERGER | 2 ma PC | ||

| 2.1.2 | Kukonzekera kwa Y-axis | |||||

| 2.1.2.1 | - Ndodo ya screw | Zosinthidwa mwamakonda | NSK | 1 ma PC | ||

| 2.1.2.2 | -Njanji | 1×MR35-C2-600-20-20-G2-V2+MRK | Malingaliro a kampani SCHNEEBERGER | 2 ma PC | ||

| 2.1.3 | Kusintha kwa Z-axis | |||||

| 2.1.3.1 | - Ndodo ya screw | Zosinthidwa mwamakonda | NSK | 1 ma PC | ||

| 2.1.3.2 | -Njanji | 1×MR25-A2-850-20-20-G2-V2+BRK+SOSPL | Malingaliro a kampani SCHNEEBERGER | 2 ma PC | ||

| 2.1.4 | Kukonzekera kwa A-axis | |||||

| 2.1.4.1 | - Encoder ya ngodya | Chithunzi cha ECN113 | HEIDENHAIN | 1 ma PC | ||

| 2.1.4.2 | - Direct drive motor | MSP-1000-2-002-158 | HIWIN | 1 ma PC | ||

| 2.1.5 | B-axis turntable | Zosinthidwa mwamakonda | GuTian | 1 ma PC | ||

| 2.1.6 | Permanent maginito awiri mutu magetsi spindle | Mphamvu yoyezedwa 7.1KW | Chuangyun | 1 pcs | ||

| 2.1.7 | Manipulator atatu axis truss | - | Chuangyun | 1 ma PC | ||

| 2.1.8 | Thireyi | Chithunzi cha 148-LP-D4 | Chuangyun | 2 ma PC | ||

| 2.1.9 | Thireyi | Chithunzi cha 148-LP-D6 | Chuangyun | 2 ma PC | ||

| 2.1.10 | Thireyi | Chithunzi cha 148-LP-D8 | Chuangyun | 2 ma PC | ||

| 2.1.11 | Clamping nsagwada | D0.5-3.2/D3.0-7.0/D7-13 | Chuangyun | 1 seti | ||

| 2.1.12 | V-block yolondola kwambiri | (3-5) | Chuangyun | 1 ma PC | ||

| 2.1.13 | V-block yolondola kwambiri | (5-7) | Chuangyun | 1 ma PC | ||

| 2.1.14 | V-block yolondola kwambiri | (6-12) | Chuangyun | 1 ma PC | ||

| 2.1.15 | Collet | D4W20 (80-00004) | Malingaliro a kampani SCHAUBLIN | 1 ma PC | ||

| 2.1.16 | Fufuzani | Mtengo wa TS150 | HEIDENHAIN | 1 ma PC | ||

| 2.1.17 | Wopera gudumu ndodo (yaitali) | 119×∅31.75×∅96mm | Chuangyun | 1 ma PC | ||

| 2.1.18 | Ndodo yopera (yaifupi) | 87×∅31.75×∅96mm | Chuangyun | 1 ma PC | ||

| 2.1.19 | Makometsedwe a mpweya | - | YUEDE | 1 ma PC | ||

| 2.1.20 | Tricolor chizindikiro nyali | DC24V | Schneider | 1 ma PC | ||

| 2.1.21 | Flowmeter | SI5000 | IFM | 1 ma PC | ||

| 2.1.22 | Yendetsani magetsi enieni | 15KW | NEWCOM | 1 ma PC | ||

| 2.1.23 | Electromagnetic valve gulu | M4GE280R-CX-E20D-5-3 | CKD | 1 seti | ||

| 2.1.24 | X,Y, Z-axis automatic lubrication system | - | Taiwan | 1 seti | ||

| 2.2 | CNC dongosolo kasinthidwe | |||||

| 2.2.1 | Mtengo wa BOXPC | IMPC00S/P1 | Newcon | 1 ma PC | ||

| 2.2.2 | Fyuluta yamagetsi | AGOFIL024A | Newcon | 1 ma PC | ||

| 2.2.3 | Fyuluta yamagetsi | AGOFIL001S | Newcon | 1 ma PC | ||

| 2.2.4 | Kukaniza | AGORES008 | Newcon | 1 ma PC | ||

| 2.2.5 | Mphamvu yayikulu yamagetsi | Chithunzi cha MDLL3015N00AN0I | Newcon | 1 ma PC | ||

| 2.2.6 | Woyendetsa wa Servo | Chithunzi cha MDLUX021B1CAN0I | Newcon | 4 ma PC | ||

| 2.2.7 | B-axis servo motor | ZLS1002-H60-D3M1-NNSB-D16E40 | Newcon | 1 ma PC | ||

| 2.2.8 | A-axis mota | MSP-1000-2-002-158 | HIWIN | 1 ma PC | ||

| 2.2.9 | Y-axis servo motor | ZLS1454-H30-DCM1-SNSB-D24E50 | Newcon | 1 ma PC | ||

| 2.2.10 | X/Z-axis servo motor | ZLS1153-H30-D3M1-NNSB-D19E40 | Newcon | 2 ma PC | ||

| 2.2.11 | U/W axis servo driver | ZLS0754-H60-D2M1-SNSB-D14E30 | Newcon | 2 ma PC | ||

| 2.2.12 | V-axis servo motor | ZLS0754-H60-D2M1-SNSB-D14E30 | Newcon | 1 ma PC | ||

| 2.2.13 | Coupler | EX-1100 | Newcon | 1 ma PC | ||

| 2.2.14 | Zolowetsa | EX-210H | Newcon | 2 ma PC | ||

| 2.2.15 | Zotulutsa | EX-310H | Newcon | 2 ma PC | ||

| 2.2.16 | Module yolowera ya analogi | EX-4054 | Newcon | 1 ma PC | ||

| 2.2.17 | Terminator | EX-TRE01 | Newcon | 1 ma PC | ||

| 2.2.18 | Operation Panel | IMOP4106/H | Newcon | 1 ma PC | ||

| 2.2.19 | NCK | IM8+ | Newcon | 1 ma PC | ||

| 2.2.20 | NCK | IMSO100006 | Newcon | 1 ma PC | ||

| 2.2.21 | NCK | IMSO100008 | Newcon | 1 ma PC | ||

| 2.2.22 | NCK | IMSO100012 | Newcon | 1 ma PC | ||

| 2.2.23 | NCK | IMPA100586 | Newcon | 1 ma PC | ||

| 2.2.24 | NCK | IMSO100373 | Newcon | 1 ma PC | ||

| 2.2.25 | NCK | IMSO100375 | Newcon | 1 ma PC | ||

| 2.2.26 | NCK | IMSO100335 | Newcon | 1 ma PC | ||

| 2.2.27 | NCK | IMSO100519 | Newcon | 1 ma PC | ||

| 2.2.28 | NCK | IMSO100392 | Newcon | 1 ma PC | ||

| 2.2.29 | NCK | IMSO100331 | Newcon | 1 ma PC | ||

| 2.2.30 | NCK | IMSO100535 | Newcon | 1 ma PC | ||

| 2.2.31 | NCK | IMSO100520 | Newcon | 1 ma PC | ||

| 2.2.32 | NCK | IMSO100560 | Newcon | 1 ma PC | ||

| 2.3 | Kukonzekera kokhazikika kwa pulogalamu yopera zida | |||||

| 2.3.1 | Wodula mphero yosavuta | Chuangyun wodzikuza | 1 ma PC | |||

| 2.3.2 | Kubowola kosavuta | Chuangyun wodzikuza | 1 ma PC | |||

| 2.3.3 | 3D kuyang'ana kugunda ndi 3D makina kayeseleledwe | Chuangyun wodzikuza | 1 ma PC | |||

| 2.3.4 | 3D chida kayeseleledwe | Chuangyun wodzikuza | 1 ma PC | |||

| 2.3.5 | Fufuzani zodziwikiratu | Chuangyun wodzikuza | 1 ma PC | |||