Makina Ophatikizana a CNC Turn-Milling

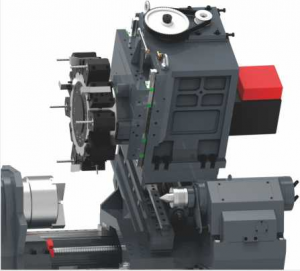

YOPHUNZITSIDWA POSITIVEYAXIS

Longmen structure, super rigid

Integrated positive Y axis structure ndi ya high-rigidity heavy cut and performance is better than interpolation Y axis.

a. Single Y axis motion heavy cutting is better than interpolation Y axis and Y axis is perpendicular to X axis.

b. Kukonzekera kozungulira kwa ndege kumakhala kosavuta komanso kosalala.

c. Zosavuta kugwiritsa ntchito pawiri komanso kukonza kozungulira.

"Positive Y" kutembenuka-mphero kuphatikiza zida ali ndi ubwino wodziwikiratu machining ndege mphero poyerekeza ndi "kutanthauzira Y" kutembenukira mphero kuphatikiza.Kuyenda kwa "Positive Y" Y-olamulira ndi perpendicular X-olamulira, amene ali limodzi. -axis movement ndi "interpolation Y" Y-axis movement ndikulowetsa mzere wowongoka kupyolera mu kayendetsedwe ka nthawi imodzi ya X-axis ndi Y-axis, flatness wa ndege yopera ndi kufananitsa "positive Y" axis - mphero kuphatikiza, "Positive Y" olamulira kutembenukira-mphero kuphatikiza processing mwachionekere owala ndi lathyathyathya.

Mpira wokhazikika kawiri

Zomangira za mpira wapamwamba kwambiri ndi maupangiri odzigudubuza ochokera kwa opanga apamwamba padziko lonse lapansi amagwiritsidwa ntchito.

Ngakhale okwera mtengo, ndi zinthu zapamwamba zokha zomwe zimatha kukwaniritsa zolondola komanso zazitali

moyo utumiki wofunidwa ndi makasitomala.

Direct-Coulled Servomotors

The servo motor imalumikizidwa mwachindunji ndi screw screw kudzera pazitsulo zachitsulo, zomwe

zimatsimikizira kuti palibe kuwonongeka ndi kusalongosoka ngakhale pansi pa katundu wolemetsa.

Izi zidzakulitsa kulondola kwa malo, ndi ulusi ndi makina a contour

zidzakhala zolondola kwambiri.

106M 108M 208M

| LTM Model | Dzina | Chigawo | 106 INE | 108 INE | 208 INE |

| Maulendo | Max. Kutembenuza Diameter pa Bedi | mm | φ600 | φ600 | φ600 |

| Max. Processing Diameter | mm | φ320 | φ300 | φ400 | |

| Max. Processing Diameter pa Tool Holder | mm | φ220 | φ220 | φ380 | |

| Max. Utali Wokonza | mm | 250 | 250 | 370 | |

| Kutalikirana Pakati pa Malo | mm | 380 | 380 | 600 | |

| Spindle Motor Hydrocylinder Tchalitchi Parameter | Mphuno ya Spindle | mtundu | A2-5 | A2-6 | A2-6 |

| Max. Kuthamanga kwa Spindle | rpm pa | 5500 | 4300 | 4200 | |

| Mafuta Cylinder / Chuck | lnch | 6” | 8” | 8” | |

| Spindle Bore | mm | φ56 | φ65 | φ65 | |

| Bar Diameter | mm | φ45 | φ52 | φ52 | |

| Direct Drive Spindle Motor Power | kw | 17.5 | 22 | 22 | |

| X/Z/Y Axis Feed Parameter | Maulendo a X | mm | 180 | 180 | 280 |

| Kufotokozera kwa Linear Guide ya X/Z | spes | 35/35 Roller | 35/35 Roller | 35/35 Roller | |

| Z Ulendo | mm | - | 300 | 600 | |

| X/Z/Y Motor Power | kw | 1.8/1.8/1.0 | 1.8/1.8/1.0 | 1.8/1.8/1.0 | |

| X/Z//Y Rapid Traverse | m/mphindi | 30/30/10 | 30/30/10 | 20/20/10 | |

| Malo Olondola | mm | ± 0.005 | ± 0.005 | ± 0.005 | |

| Bwerezani Kulondola Kwakayimidwe | mm | ± 0.003 | ± 0.003 | ± 0.003 | |

| Parameter ya Turret | Chida Malo | ma PC | Chithunzi cha BMT45-12T | Chithunzi cha BMT45-12T | Chithunzi cha BMT55-12T |

| Mphamvu ya Turret Motor | kw | 2.2/3.7 | 2.2/3.7 | 2.2/3.7 | |

| Square Tool Holder | mm | 20 × 20 | 20 × 20 | 20 × 20 | |

| Round Boring Tool Holder | mm | φ32 | φ32 | φ40 | |

| Nthawi Yosintha Chida Chapafupi | mphindi | 0.15 | 0.15 | 0.15 | |

| Malo Olondola | / | ±2” | ±2” | ±2” | |

| Bwerezani Kulondola Kwakayimidwe | / | ±1” | ±1” | ±1” | |

| Tailstock Parameters | Programmable Hydraulic Tailstock | / | √ | √ | |

| Max. Ulendo wa Tailstock | mm | 360 | 360 | 440 | |

| Tailstock Sleeve Taper Hole | mtundu | MT 5# | MT 5# | MT 5# | |

| Diameter ya Sleeve | mm | / | / | / | |

| Maulendo a Manja | mm | / | / | / | |

| Kukula Kwamakina | Kukula Kwa Makina | mm | 2300×1800×1700 | 2300×1800×1700 | 2620×2200×1920 |

| Kulemera kwa Makina | kg | 3700kg | 3800kg | 5200kg |

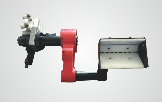

Servo Automatic Bar Feeder

TENOLY feeders imakhala ndi ntchito yolemetsa komanso yopangidwa ndi makina,

Imawonjezera zokolola komanso imathandizira kutembenuza.

Part Catcher

Chombo chogwirira ntchito chimapangidwa ndi mfundo yolumikizira makina, yomwe imatha kukhala mwachangu

olumikizidwa ndi chomalizidwa pambuyo pokonza.

THK wodzigudubuza mzere wowongolera

Wowongolera mzere ali ndi chilolezo cha zero, kudula kwa arc, kudula kwa bevel, ndipo mawonekedwe ake ndi ofanana. Ndi yoyenera kwa opareshoni yothamanga kwambiri ndipo imachepetsa kwambiri mphamvu yamahatchi ofunikira pamakina a Linear guide njanji amagwiritsa ntchito kugubuduza m'malo motsetsereka, ndikuwonongeka pang'ono, kuyankha tcheru komanso kulondola kwambiri. Imatha kunyamula katunduyo mmwamba, pansi, kumanzere ndi kumanja nthawi yomweyo. Pansi pa katunduyo, malo okhudzana ndi njanji akadali okhudzana ndi mfundo zambiri, ndipo kukhazikika kwa kudula sikudzachepetsedwa; Msonkhano wosavuta komanso wosinthika komanso mawonekedwe osavuta opaka mafuta; maupangiri amzere amakhala ochepa kwambiri komanso okhalitsa.

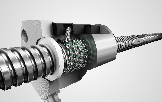

THK Mpira Screw

Pogwiritsa ntchito zomangira zolondola kwambiri za mpira, zodzaza ndi mtedza ndi wononga

kudzinamizira mankhwala, mmbuyo ndi kutentha kukwera ndi

elongation amachotsedwa pasadakhale, kusonyeza malo abwino kwambiri

ndi repeatability.

Kuyendetsa molunjika ndi servo motor kuti muchepetse zolakwika zobwerera.

High Precision Motorized Arm ya Lathe

Chokhazikitsira chida chokokera pansi chokhala ndi kubwereza kolondola kwambiri Chopezeka mumitundu yosiyanasiyana kuti chikwaniritse zosowa zosiyanasiyana zamafakitale Zopezeka mumiyeso yosiyanasiyana yofananira, komanso zida zoyezera zachitsulo zopangidwa mwamakonda zokhala ndi coefficient yochepera yakukulitsa.

Gwiritsani ntchito probe yamphamvu ya zirconia

Zimatenga malo ochepa pamakina osagwiritsidwa ntchito

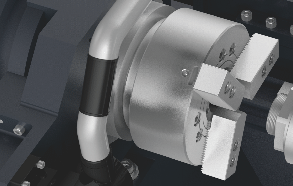

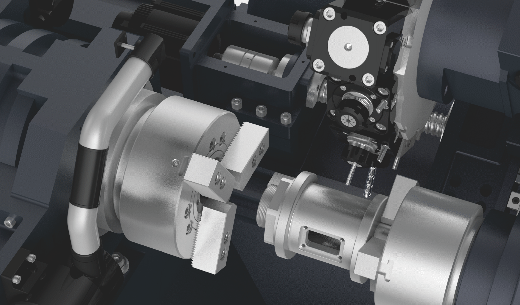

Hydraulic Chuck Workholding

Lathe ili ndi hydraulic through-hole chuck monga muyezo. Chuck imatha kusinthidwa malinga ndi zosowa za makasitomala, ndipo zosankha zingapo zidzakupatsani chuck yoyenera kwambiri.

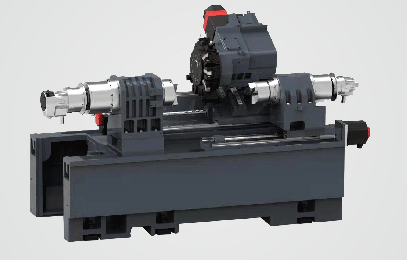

Sekondale Spindle

Malekezero onse a workpiece akhoza kupangidwa nthawi imodzi mu clamping imodzi, yomwe imapangitsa kuti ntchitoyo ikhale yosavuta.