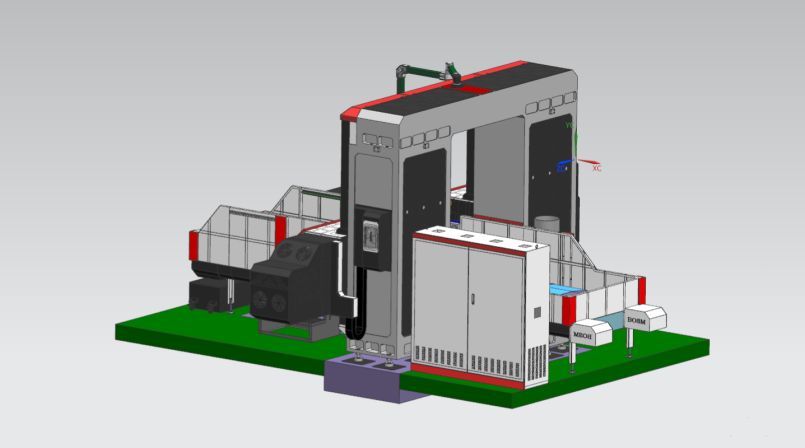

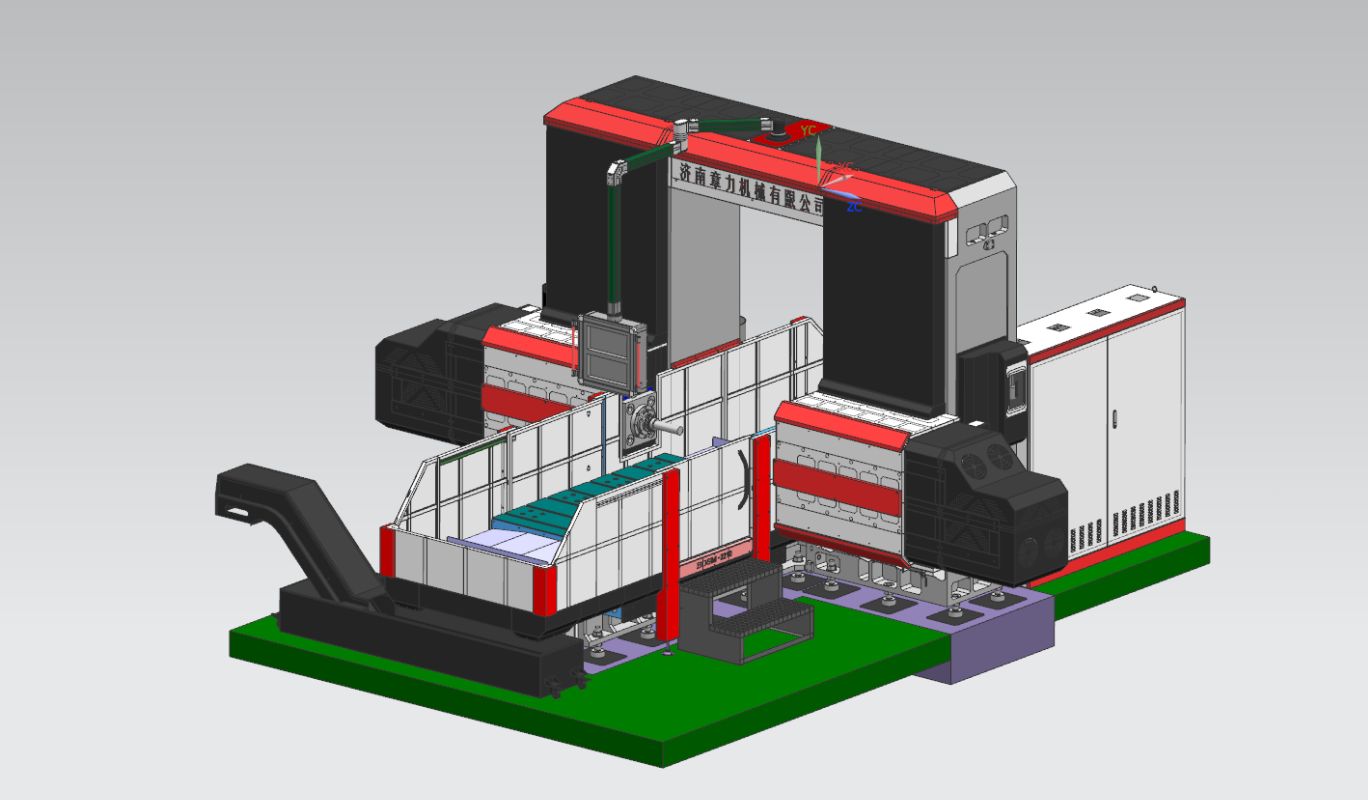

BOSM -5020-5Z Otsutsa-Mutu Wotopetsa Makina Ogaya

1. Kugwiritsa ntchito zida:

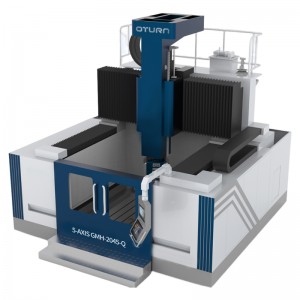

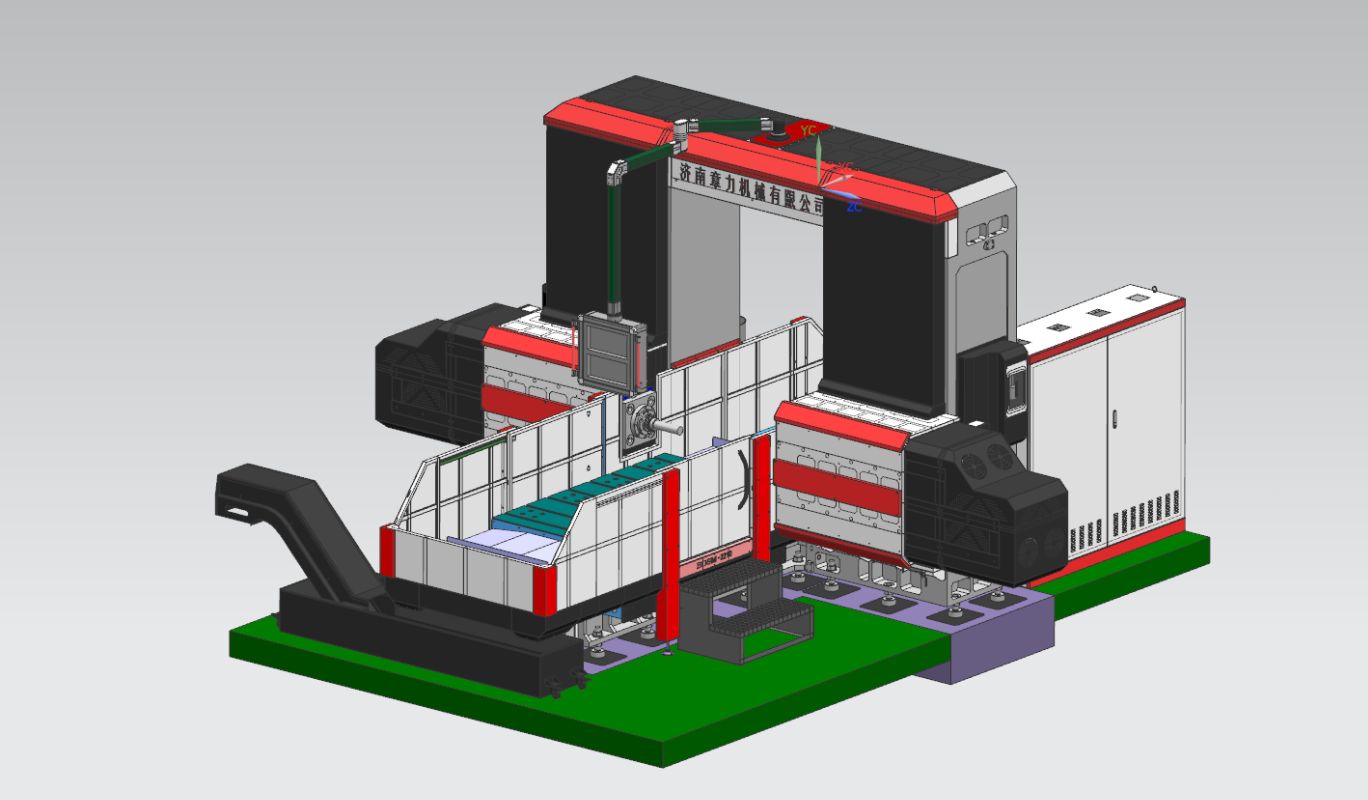

BOSM-5020-5Z CNC workbench mobile double-column mutu-to-head wotopetsa ndi mphero makina ndi wapadera Machine kwa uinjiniya symmetrical workpieces makina. Makinawa ali ndi benchi yapadera yosunthika komanso ma seti awiri ankhosa zopingasa, zomwe zimatha kuzindikira Kubowola, mphero, kunyowa ndi zina zogwirira ntchito mkati mwa sitiroko yogwira ntchito, chogwiriracho chimatha kukonzedwa m'malo nthawi imodzi (palibe chifukwa yachiwiri clamping), kudya Mumakonda ndi kutsitsa liwiro, kusala malo liwiro, mkulu processing kulondola ndi mkulu processing dzuwa.

2. Kapangidwe kazida:

2.1. Zigawo zazikulu za Machine

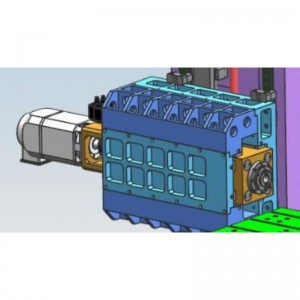

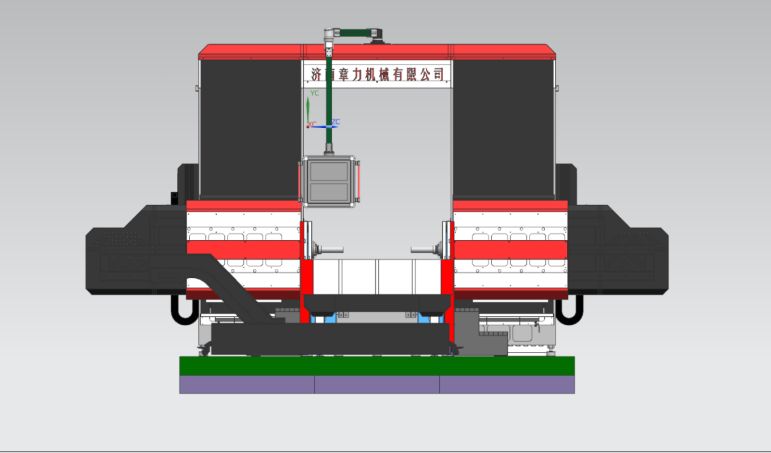

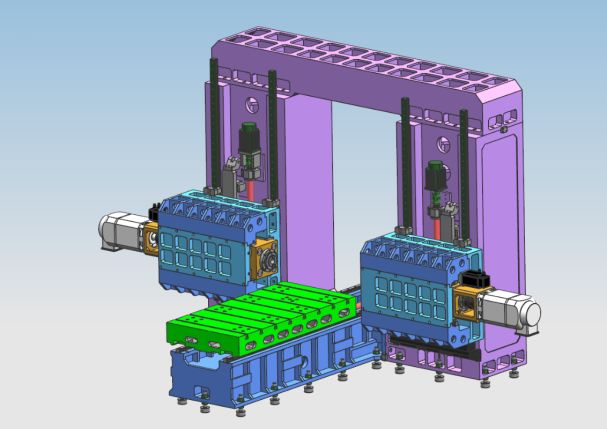

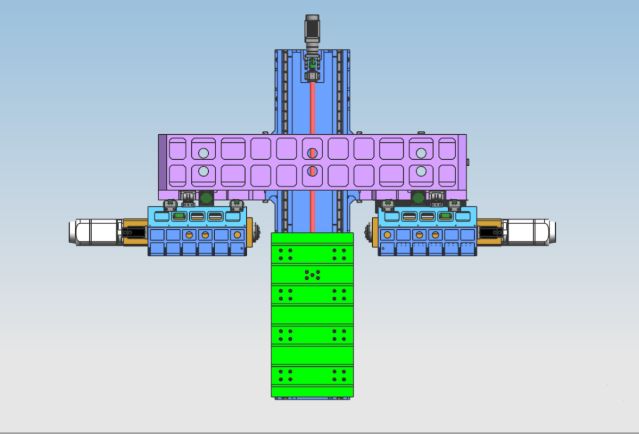

Bedi, benchi, zipilala kumanzere ndi kumanja, matabwa, matabwa olumikiza matabwa, zishalo, nkhosa zamphongo, ndi zina zotero, zonse zimapangidwa ndi utomoni wa mchenga, chitsulo chamtengo wapatali cha 250 choponyedwa, chomangidwira mu dzenje la mchenga wotentha → kugwedera kukalamba → ng'anjo yamoto → kugwedera kukalamba→kukonza mwaukali→kugwedera kugwedera→kuyatsa ng'anjo→kunjenjemera kukalamba→kumaliza, kuthetsa kupsinjika koyipa kwa magawowo, ndikusunga magwiridwe antchito kukhala okhazikika. Bedi lokhazikika, mizati yakumanzere ndi yakumanja, gantry, ndi kusuntha kwa benchi; Makina ali ndi mphero, Kudula kotopetsa, kubowola, kuwerengera, kugogoda ndi ntchito zina, njira yoziziritsira chida ndi kuzizira kwakunja, Makinawa ali ndi nkhwangwa 5 zodyetsa, zomwe zimatha kuzindikira kulumikizana kwa 4-axis, 5-axis single-action, 2 mitu yamphamvu. , Machine axial ndi Mutu wa mphamvu ukuwonetsedwa mu chithunzi pansipa.

2.2. Kapangidwe kake ka gawo la chakudya cha axial

2.2.1. X-axis: Zogwirira ntchito zimabwereranso motsatira njanji yowongolera pabedi lokhazikika.

Kutumiza kwa X-axis: AC servo motor ndi chochepetsera chapamwamba kwambiri cha mapulaneti chimagwiritsidwa ntchito kuyendetsa chogwirira ntchito kudzera pa transmission ya mpira wononga kuti izindikire X-axis linear motion.

Mawonekedwe a njanji yowongolera: ikani njanji ziwiri zolondola kwambiri zolondola kwambiri

2.2.2.Y1 axis: Mutu wa mphamvu ndi nkhosa yamphongo zimayikidwa molunjika kumbali ya kutsogolo kwa chigawocho, ndipo zimabwezerana kumanzere ndi kumanja motsatira njanji yolondolera pazanja.

Kutumiza kwa Y1-axis: AC servo motor imagwiritsidwa ntchito kuyendetsa wononga mpira kuyendetsa chishalo kuti chisunthe, ndikuzindikira kuyenda kwa mzere wa Y1-axis.

Fomu yowongolera njanji: 4 zidutswa za 45 mtundu wa njanji zowongolera.

2.2.3.Y2 axis: Nkhosa yamphongo yachiwiri ya mutu wa mphamvu imayikidwa molunjika kumbali ya kutsogolo kwa chigawocho, ndipo imabwereza kumanzere ndi kumanja motsatira njanji yolondolera pamzati.

Kutumiza kwa Y2-axis: AC servo motor imagwiritsidwa ntchito kuyendetsa wononga mpira kuyendetsa chishalo kuti izindikire kuyenda kwa mzere wa Y1-axis.

Fomu yowongolera njanji: 4 zidutswa za 45 mtundu wa njanji zowongolera

2.2.4. Z1 axis: Chishalo chotsetsereka chamutu champhamvu chimayikidwa molunjika kutsogolo kwa gawo lakumanja, ndikubweza mmwamba ndi pansi motsatira njanji yowongolera.

Z1-axis transmission: AC servo motor ndi chochepetsera chapamwamba kwambiri cha mapulaneti chimagwiritsidwa ntchito kuyendetsa nkhosa yamphongo kuti idutse pa screw screw kuti izindikire kuyenda kwa mzere wa Z1-axis.

Fomu yowongolera njanji: 2 65 mtundu wa njanji zowongolera

2.2.5.Z2 axis: Chishalo cha slide champhamvu chamutu chimayikidwa choyimirira kutsogolo kwa ndime yakumanja, ndikubweza mmwamba ndi pansi motsatira njanji yowongolera.

Kutumiza kwa Z1-axis: AC servo motor kuphatikiza chotsitsa chapamwamba kwambiri cha mapulaneti chimagwiritsidwa ntchito kuyendetsa nkhosa kuti idutse pa screw screw kuti izindikire kuyenda kwa mzere wa Z2-axis.

Fomu yowongolera njanji: 2 65 mtundu wa njanji zowongolera

Mzere wapamwamba wa HT250 woponyera 2 zidutswa za 65 mtundu wolemetsa wolozera njanji

Mutu wamphamvu wotopetsa komanso wogaya (kuphatikiza mutu wamagetsi 1 ndi 2) ndi nkhosa yamphongo yayikulu, ndipo njira yosunthira imatsogozedwa ndi njanji 4 zowongolera zozungulira. Kuyendetsa kumagwiritsa ntchito injini ya AC servo kuti iwongolere peyala yolondola ya mpira. Makinawa ali ndi nitrogen balance bar. , Chepetsani mphamvu yonyamula mutu wa makina pa screw ndi servo motor. Galimoto ya Z-axis ili ndi ntchito yoboola yokha. Kukanika mphamvu, mabuleki odziwikiratu amasunga shaft yamotoyo mwamphamvu kuti isazungulire. Pogwira ntchito, chobowolacho sichikhudza chogwirira ntchito, chidzadya mofulumira; pamene kubowola pang'ono kukhudza workpiece, izo basi kusinthana ntchito chakudya. Pamene kubowola pang'ono likulowerera workpiece, izo basi kusinthana kudya rewind; pamene mapeto a kubowola pang'ono kusiya workpiece ndi kufika malo anapereka, izo kusamukira ku dzenje lina malo kuzindikira kufalitsidwa basi. Ndipo imatha kuzindikira ntchito za kubowola mabowo akhungu, mphero, chamfering, chip breaking, automatic chip kuchotsa, etc., zomwe zimathandizira zokolola zantchito.

Mutu wa mphamvu ya 500mm wa square ram mphamvu umagwiritsa ntchito maulozera amzere m'malo mwa zoyika zachikhalidwe kuti ziwongolere kulondola kolondola ndikusunga kulimba kwa sikweya yamphongo.

2.3. Kuchotsa chip ndi kuziziritsa

Pali ma spiral and flat chain chip conveyors omwe amaikidwa mbali zonse pansi pa benchi yogwirira ntchito, ndipo tchipisi titha kuperekedwa kwa chotengera cha chip kumapeto kwa magawo awiri amizere yozungulira ndi maunyolo kuti akwaniritse chitukuko chotukuka. Muli mpope wozizirira mu thanki yoziziritsira ya chotengera cha chip, yomwe ingagwiritsidwe ntchito poziziritsa kunja kwa chidacho kuti zitsimikizire kugwira ntchito ndi moyo wautumiki wa chidacho, ndipo choziziriracho chikhoza kusinthidwanso.

3. Dongosolo lathunthu lowongolera manambala a digito:

3.1. Ndi chip breaking function, chip breaking time ndi chip breaking cycle zitha kukhazikitsidwa pamakina amunthu.

3.2. Okonzeka ndi chida chokweza ntchito, chida chokweza mtunda chikhoza kukhazikitsidwa pa mawonekedwe a makina a munthu. Mtunda ukafika, chidacho chimakwezedwa mwachangu, ndiye tchipisi timatayidwa, ndiyeno chimatumizidwa mwachangu kumalo obowola ndikusinthidwa kuti chigwire ntchito.

3.3. Bokosi lapakati loyang'anira ntchito ndi gawo logwiridwa pamanja limatenga makina owongolera manambala ndipo ali ndi mawonekedwe a USB ndi chiwonetsero cha LCD chamadzimadzi. Pofuna kuwongolera mapulogalamu, kusungirako, kuwonetsera ndi kulankhulana, mawonekedwe ogwiritsira ntchito ali ndi ntchito monga kukambirana ndi makina a munthu, kubwezera zolakwika, ndi alamu yokha.

3.4. Zidazi zimakhala ndi ntchito yowoneratu ndikuwunikanso malo a dzenje musanayambe kukonza, ndipo ntchitoyi ndi yabwino kwambiri.

4. Makina opaka mafuta

Makina owongolera njanji olondola kwambiri, mawotchi olondola a mpira ndi zina zoyenda zolondola kwambiri zili ndi makina odzipaka okha. Pampu yodzitchinjiriza yokha imatulutsa mafuta othamanga, ndipo chipinda chamafuta opangira mafuta ochulukirapo chimalowa mumafuta. Chipinda chamafuta chikadzadza ndi mafuta, pamene kupanikizika kwa dongosolo kumakwera kufika ku 1.4-1.75Mpa, kusinthana kwachitsulo mu dongosolo kumatsekedwa, mpope umayima, ndipo valve yotsitsa imatsitsa nthawi yomweyo. Kuthamanga kwamafuta mumsewu kutsika pansi pa 0.2Mpa, mafuta ochulukirapo amayamba kudzaza malo opaka mafuta ndikumaliza kudzaza mafuta amodzi. Chifukwa cha kupezeka kwamafuta olondola a jekeseni wamafuta ochulukirachulukira komanso kuzindikira kupanikizika kwadongosolo, mafutawo ndi odalirika, kuwonetsetsa kuti pagulu lililonse la kinematic pali filimu yamafuta, kuchepetsa mikangano ndi kuvala, ndikuletsa kuwonongeka. kapangidwe ka mkati chifukwa cha kutentha kwambiri. , kuonetsetsa kulondola ndi moyo wa Machine. Poyerekeza ndi njanji yolowera njanji yotsetsereka, njanji yoyenda pamzere yomwe imagwiritsidwa ntchito mu Makinawa ili ndi zabwino zingapo:

①Kukhudzidwa kwamayendedwe ndikwambiri, kugundana kwa njanji yowongolera ndi yaying'ono, 0.0025 ~ 0.01 yokha, ndipo mphamvu yoyendetsa imachepetsedwa kwambiri, yomwe ikungofanana ndi 1/10 yamakina wamba.

② Kusiyana pakati pa kukangana kosunthika ndi kocheperako ndikochepa kwambiri, ndipo kutsata kotsatira ndikwabwino kwambiri, ndiye kuti, nthawi yapakati pakati pa siginecha yoyendetsa ndi kachitidwe ka makina ndi yayifupi kwambiri, yomwe imathandizira kuwongolera liwiro komanso kukhudzika kwa dongosolo lowongolera manambala.

③Ndioyenera kuyenda mothamanga kwambiri, ndipo liwiro lake pompopompo limakwera pafupifupi ka 10 kuposa la njanji zotsetsereka.

④ Imatha kuzindikira kusuntha kopanda malire ndikuwongolera kusasunthika kwamakina.

⑤Zopangidwa ndi akatswiri opanga, zimakhala zolondola kwambiri, zosinthika bwino komanso zosavuta kukonza.

5.Kuyang'ana kwa laser-axis atatu:

Makina aliwonse a Bosman amayesedwa ndi laser interferometer ya kampani ya RENISHAW ku United Kingdom kuti ayang'ane molondola ndikubwezera cholakwika cha phula, kubweza, kulondola kwa malo, kubwereza kulondola kwa malo, ndi zina zambiri, kuwonetsetsa kukhazikika, kusasunthika komanso kulondola kwa makinawo. makina. Kuwunika kwa Ballbar Makina aliwonse amagwiritsa ntchito ballbar kuchokera ku kampani yaku Britain ya RENISHAW kuti athe kuwongolera kulondola kwa bwalo ndi makina olondola a geometric, ndikuyesa kuyesa kozungulira nthawi imodzi kuonetsetsa kuti makina a 3D ali olondola komanso ozungulira makinawo.

6. Malo ogwiritsira ntchito makina:

6.1. Zofunikira zachilengedwe zogwiritsira ntchito zida

Kusunga mulingo wokhazikika wa kutentha kozungulira ndikofunikira kwambiri pakukonza makina.

(1) Zofunikira zopezeka zozungulira kutentha ndi -10 ° C mpaka 35 ° C, pamene kutentha kwapakati ndi 20 ° C, chinyezi chiyenera kukhala 40% mpaka 75%.

(2) Kuti musunge kulondola kwapang'onopang'ono kwa Machine mkati mwazomwe zafotokozedwa, kutentha koyenera kozungulira kumafunika kukhala 15 ° C mpaka 25 ° C, ndipo kusiyana kwa kutentha sikudutsa ± 2 ° C / 24h.

6.2. Magetsi amagetsi: magawo atatu, 380V, mkati mwa ± 10% kusinthasintha kwamagetsi, ma frequency amagetsi: 50HZ.

6.3. Ngati voteji yomwe ikugwiritsidwa ntchito ndi yosakhazikika, Makinawa ayenera kukhala ndi magetsi okhazikika kuti atsimikizire kuti makinawo akugwira ntchito bwino.

6.4. Makinawa ayenera kukhala ndi maziko odalirika: waya woyika pansi ndi waya wamkuwa, waya wakuya sikuyenera kuchepera 10mm², ndipo kukana kwapansi kuyenera kukhala kosakwana 4 ohms.

6.5. Kuti zitsimikizire kuti zidazo zimagwira ntchito bwino, ngati mpweya woponderezedwa wa gwero la mpweya sungathe kukwaniritsa zofunikira za gwero la mpweya, zida zoyeretsera magwero a mpweya (dehumidification, degreasing, kusefa) ziyenera kuonjezedwa musanatenge mpweya. wa Makina.

6.6. Sungani zidazo kutali ndi kuwala kwa dzuwa, kugwedezeka ndi kutentha, majenereta othamanga kwambiri, makina owotcherera amagetsi, ndi zina zotero, kuti mupewe kulephera kupanga makina kapena kutayika kwa makina olondola.

7.Zosintha zaukadaulo:

| Chitsanzo | 5020-5Z | |

| Zolemba malire processing workpiece kukula | Utali × m'lifupi × kutalika (mm) | 5000×2000×2500 |

| Gantry maximum feed | M'lifupi (mm) | 2300 |

| saizi ya desiki yogwira ntchito | Utali X M'lifupi (mm) | 5000*2000 |

| Kuyenda patebulo | Bench yogwirira ntchito imayenda mmbuyo ndi mtsogolo (mm) | 5000 |

| Nkhosa ziwiri zamphongo zikweze mmwamba ndi pansi | Kugunda mmwamba ndi pansi kwa nkhosa yamphongo (mm) | 2500 |

| Yopingasa nkhosa yamphongo mtundu kubowola mutu mphamvu mutu mmodzi awiri | Kuchuluka (2) | 2 |

| Yopingasa nkhosa yamphongo mtundu kubowola mutu mphamvu mutu mmodzi awiri | Spindle taper | Mtengo wa BT50 |

| Liwiro la spindle (r/min) | 30-5000 | |

| Servo spindle motor power (kw) | 37*2 | |

| Mtunda pakati pa malo a mphuno kumapeto kwa nsonga ziwiri (mm) | 1500-2500 mm | |

| Kugunda kumanzere ndi kumanja kwa nkhosa yamphongo imodzi (mm) | 500 | |

| Kumenya kumanzere ndi kumanja kwa nkhosa yamphongo iwiri (mm) | 1000 | |

| Bidirectional Positioning Kulondola | 300mm * 300mm | ± 0.025 |

| Bi-directional kubwereza malo olondola | 300mm * 300mm | ± 0.02 |

| Kulemera kwakukulu (t) | (pafupifupi) 55 | Kulemera kwakukulu (t) |