Center Drive lathe Kwa Thin-mipanda chubu

Machubu okhala ndi mipanda yopyapyala ndi Zigawo za Tube

Technology Solution

1.Kusanthula kachitidwe ka kukonza magawo a cylindrical okhala ndi mipanda yopyapyala

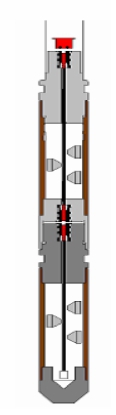

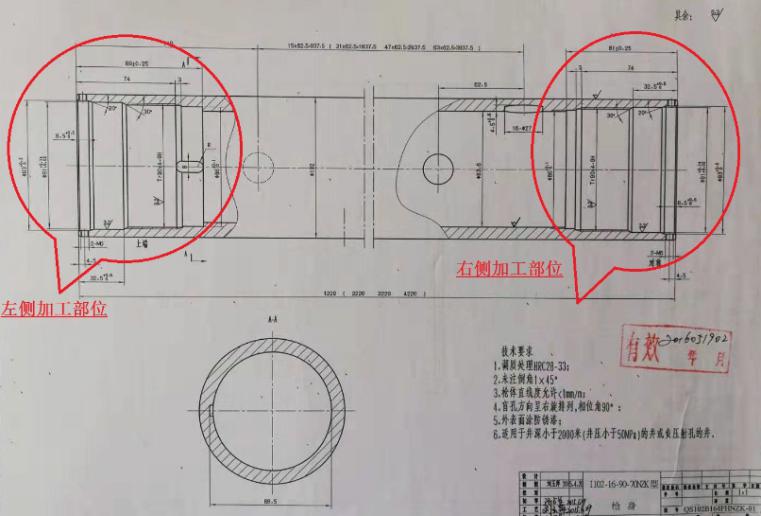

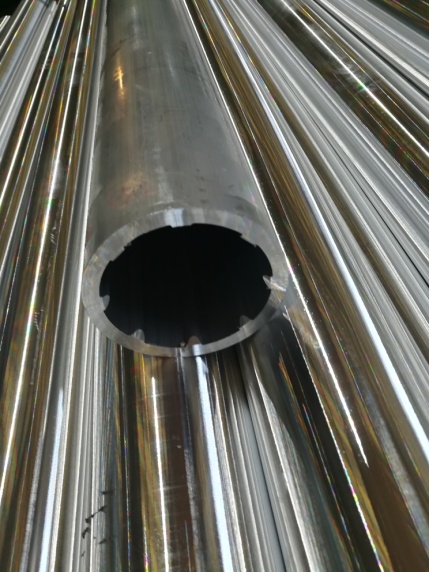

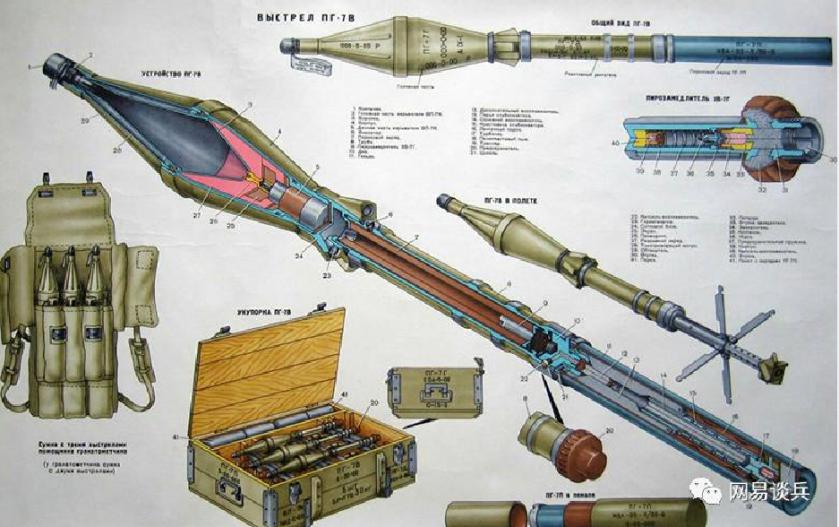

Machubu okhala ndi mipanda yopyapyala ndi machubu nthawi zonse akhala chinthu chovuta pakukonza. Mwachitsanzo: mfuti ya perforating ya zida zowonongeka zomwe zimagwiritsidwa ntchito pobowola makina a petroleum, chipolopolo chamkati ndi chakunja cha downhole shock absorber, mkati ndi kunja kwa chipolopolo cha pampu ya mafuta, ng'oma yosindikizira ya makina osindikizira, ng'oma yozungulira. Makina opangira nsalu, makina otumizira ma Conveyor roller, kubowola pansi pa dzenje ndi zida zophulitsira

Chophimba chakunja, ndi zina zotero, chimaphatikizaponso zipolopolo zankhondo kapena zipolopolo za anthu wamba.

1.1 Zigawo zofananira

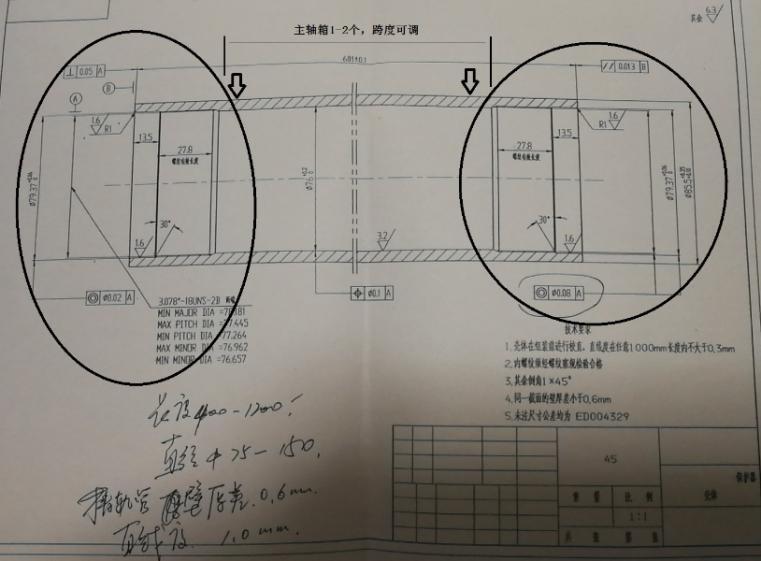

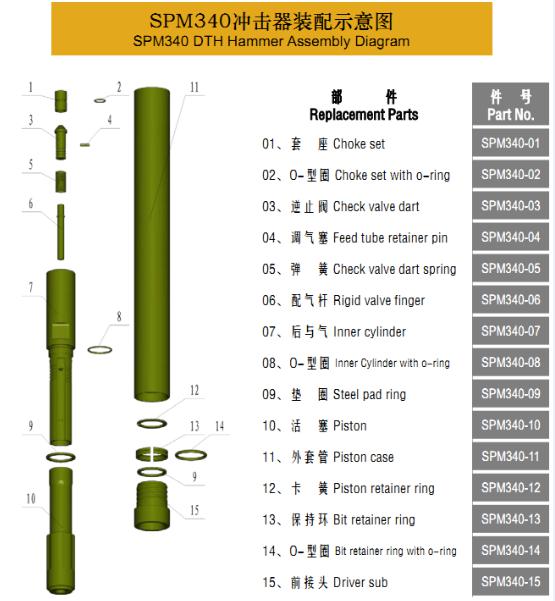

Mapangidwe a mfuti ya perforating: zigawo zikuluzikulu za mfuti ya perforating ndi thupi lamfuti, mutu wa mfuti, mchira wa mfuti, mgwirizano wapakati, chowonjezera cha detonation, mphete yosindikiza ndi chosungira katiriji. Zofunikira pakugwirira ntchito kwa mfuti yowombera. Monga gawo lalikulu la perforator yopangidwa ndi mphamvu, ntchito yaikulu ya mfuti ya perforating ndiyo mphamvu yake yamakina. Pokhapokha pamene katundu wake wamakina akumana, wobowoleza wopangidwa ndi mphamvu angatsimikizidwe Kuthekera ndi chitetezo pakubowola pansi.

Woteteza pompa mafuta

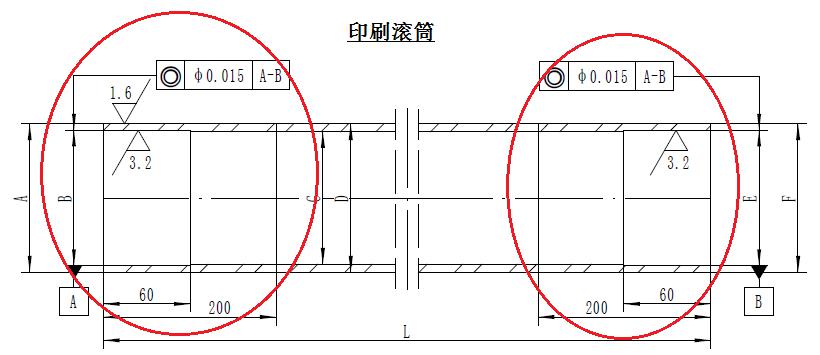

Silinda yosindikiza

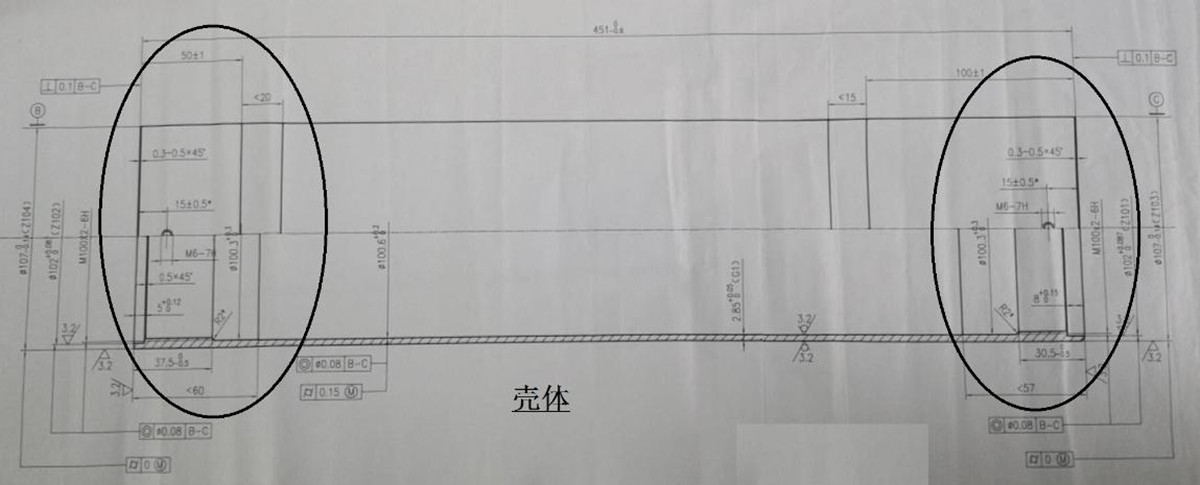

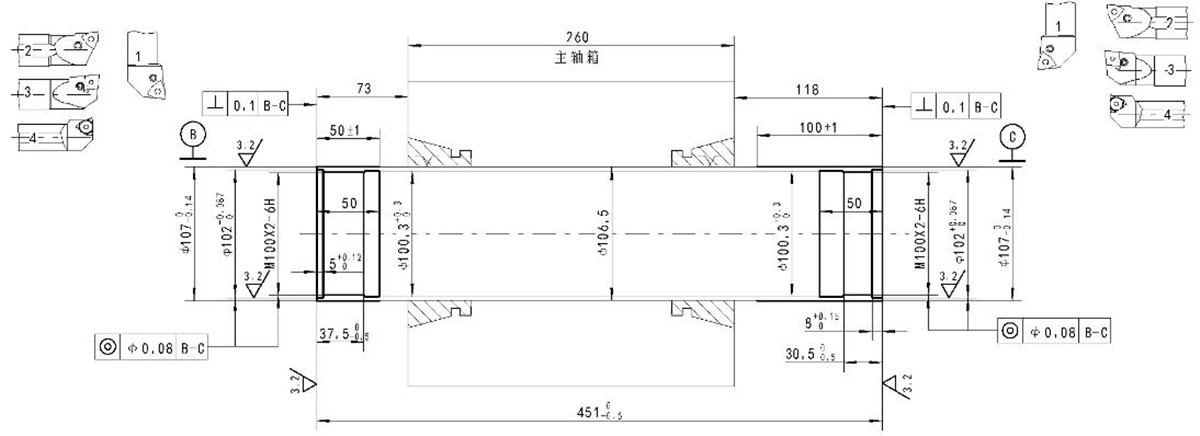

Kuyerekeza kwaukadaulo watsopano ndi wakale wa impactor chipolopolo

Zigawo zamtundu uwu zili ndi chinthu chimodzi chofanana: mapaipi opyapyala opangidwa ndi kugudubuza kapena kupota amakonzedwa makamaka kumapeto onse awiri, kuima kwa dzenje lamkati (kwa msonkhano), ulusi wamkati wa dzenje (kugwirizanitsa), bwalo lakunja lakunja, ulusi wakunja ( ngati Ndikofunikira), mkati ndi kunja sipes opanda kanthu ndi chamfer

1.2. Kusanthula ndondomeko.

1) Ukadaulo waukadaulo wachikhalidwe:

Nthawi zambiri, mbali imodzi ya lathe imagwiritsidwa ntchito pokhomerera, ndipo kumapeto kwina kumagwiritsa ntchito tailstock pamwamba pa dzenje lamkati ndi chimango chapakati chagalimoto, kenako gwiritsani ntchito chimango chapakati kuti chithandizire, kenako ndikubowola bowo lamkati. , mapeto a galimoto, ndi makina omwe angafunikire kuti atembenuzire mbali zakunja za bwalo, kapena zigawo zomangirira zomwe zimafunikila kutembenuka ndi kutembenuka.

Workpiece U-turn: Thandizo lamkati kapena thupi lakunja lotchinga, tailstock imalimbitsa chogwirira ntchito, socket yapakati yamagalimoto, chothandizira chimango chapakati, bowo lamkati loboolanso, nkhope yomaliza yagalimoto, bwalo lakunja.

Ngati coaxiality wa mabowo amkati pa malekezero onse a silinda ndi apamwamba pang'ono, processing akhoza kubwerezedwa kangapo.

2) Kugwiritsa ntchito ukadaulo wapawiri CNC lathe processing:

The processing wa zili pamwamba akhoza kutha mu clamping imodzi, ndipo malekezero onse akhoza kukonzedwa pa nthawi yomweyo, amene osati kuchepetsa chiwerengero cha zida makina, komanso kufupikitsa ndondomeko otaya ndi kusamalira zinthu, ndipo kwambiri bwino kupanga Mwachangu. . Popeza mbali zonse ziwiri zimakonzedwa nthawi imodzi, coaxiality ya workpiece imatsimikiziridwa modalirika.

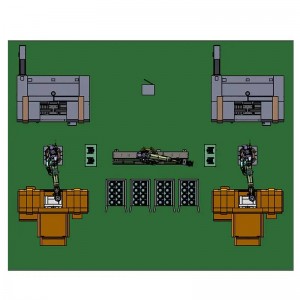

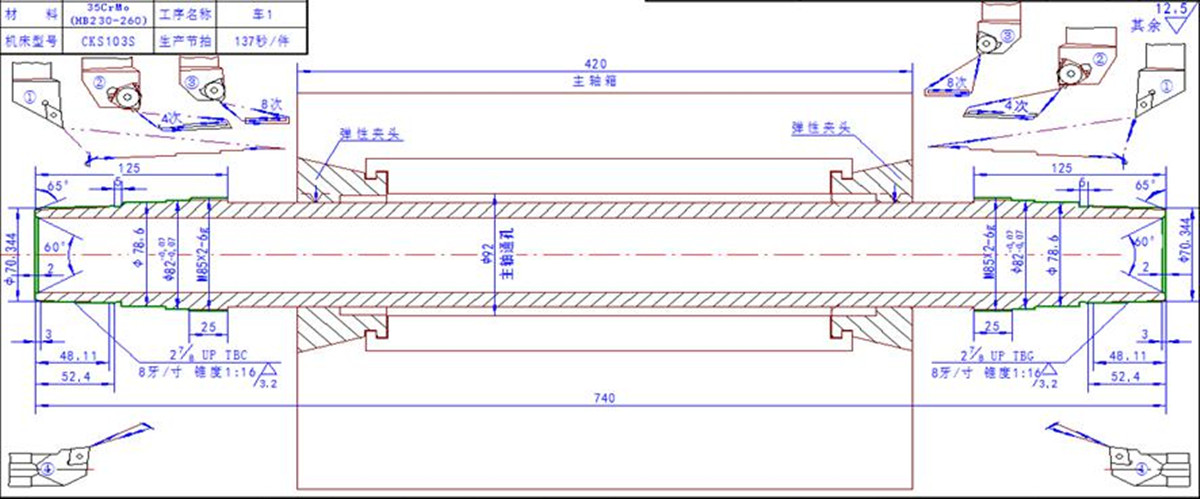

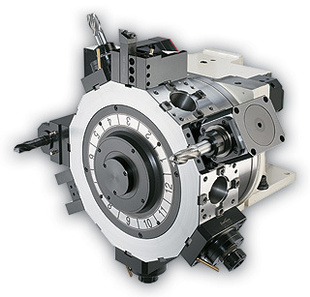

Mwachindunji: kutengera kutalika kwa chogwiriracho, mutu umodzi kapena ziwiri zitha kugwiritsidwa ntchito kukakamiza bwalo lakunja la chogwiriracho. The clamping awiri ndi clamping m'lifupi wa headstock anatsimikiza molingana ndi awiri ndi kutalika kwa workpiece. Ma 8/12-station turrets ozungulira Pamodzi amakonza nkhope yomaliza, dzenje lamkati ndi bwalo lakunja mbali zonse ziwiri. Monga kuchuluka kwa zida zomwe zitha kukhazikitsidwa ndizokwanira, zimatha kukwaniritsa nthawi imodzi yokonza magawo ovuta.

Ngati mbali yakunja yokhotakhota ya chida cha makina muzotsatirazi ikuyenera kukonzedwa, ndiye gwiritsani ntchito chida cha makina kuti mukweze mabowo amkati kumapeto onse awiri a workpiece kuti mutembenuze kapena pogaya bwalo lakunja.

Palinso makasitomala omwe amagwiritsa ntchito chopukusira chopanda pakati kuti agaye bwalo lakunja pasadakhale, ndiyeno amagwiritsa ntchito lathe yapawiri ya CNC kuti akonze mabowo amkati ndi nkhope zomaliza kumapeto onsewo kuti akwaniritse zofunikira.

3) Milandu ya cylindrical mbali kukonzedwa ndi awiri-mapeto CNC lathes:

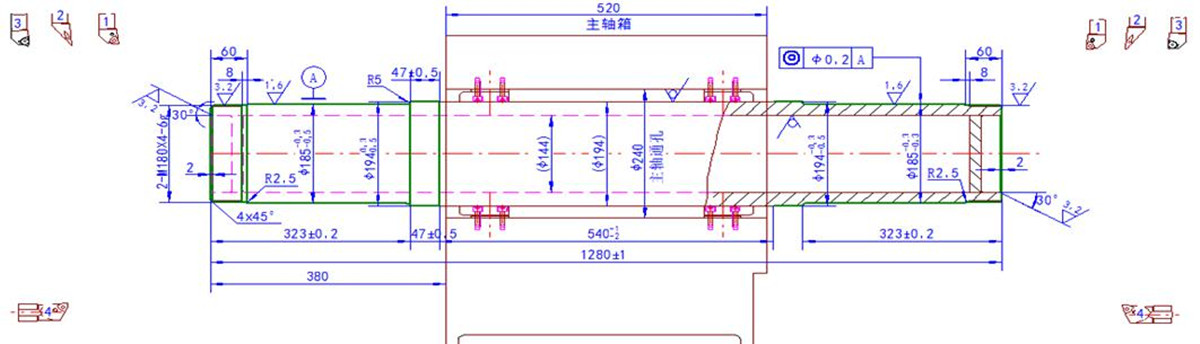

①Kukonza silinda yamakina osindikizira, sankhani mtundu wa SCK208S (pogwiritsa ntchito bokosi lopotana pawiri).

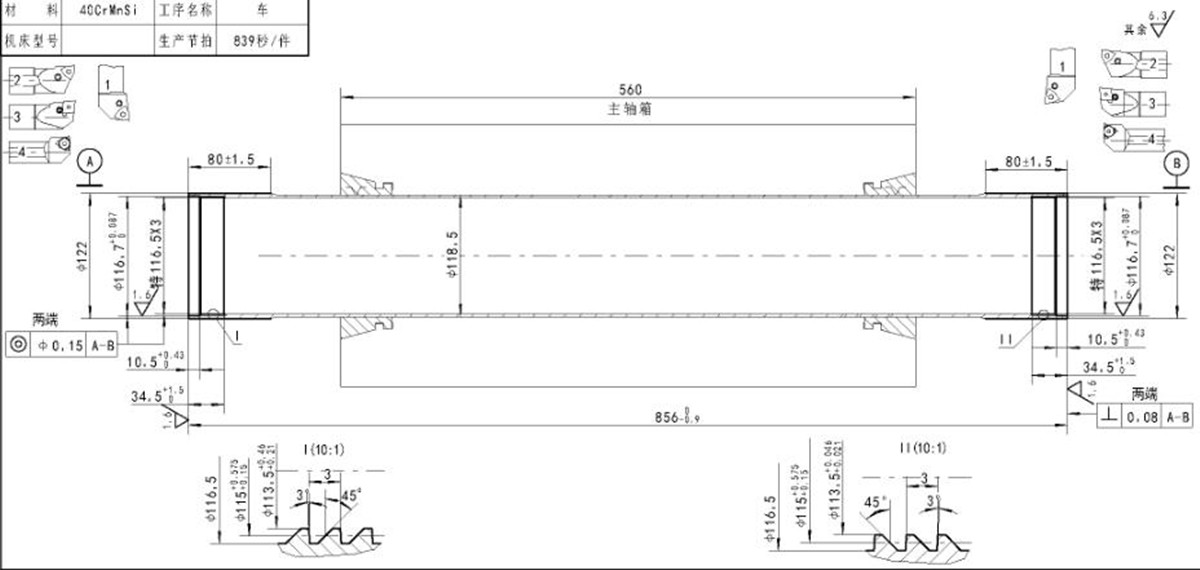

②Mtundu wa SCK309S (mutu umodzi) umagwiritsidwa ntchito pokonza ekisi yapakati yagalimoto.

③SCK105S mtundu umagwiritsidwa ntchito pokonza machubu ankhondo okhala ndi mipanda yopyapyala.

④Pokonza machubu ankhondo okhala ndi mipanda yopyapyala, sankhani mtundu wa SCK103S

⑤ SCK105S mtundu wasankhidwa pokonza mapaipi amafuta amakina amafuta.

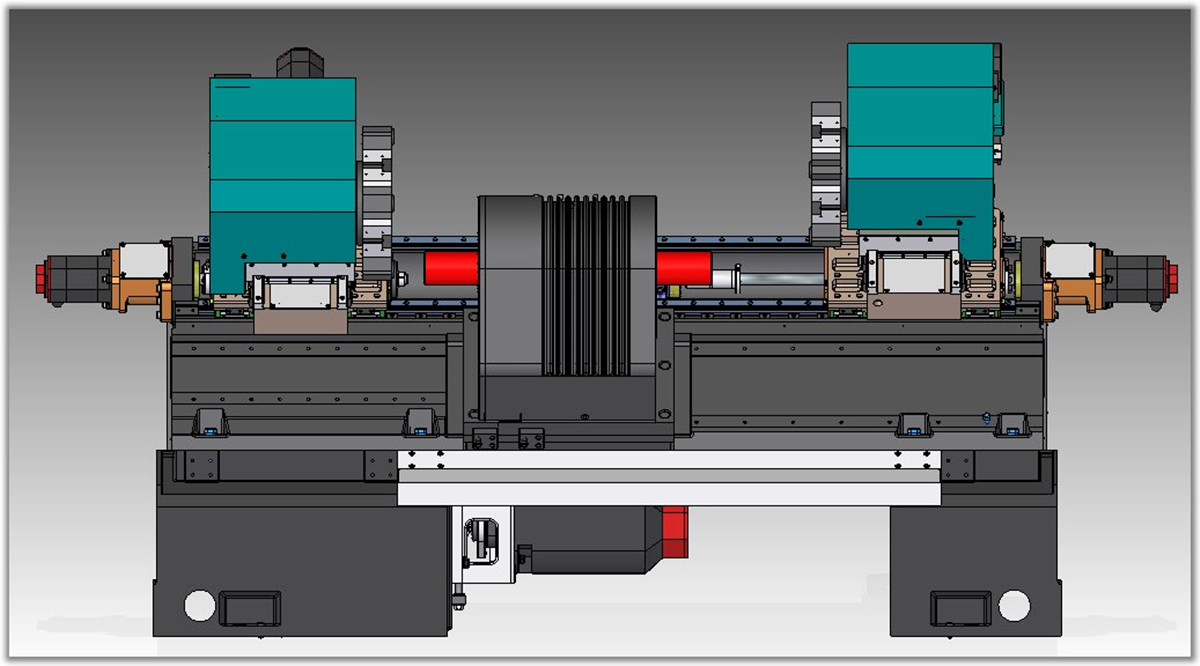

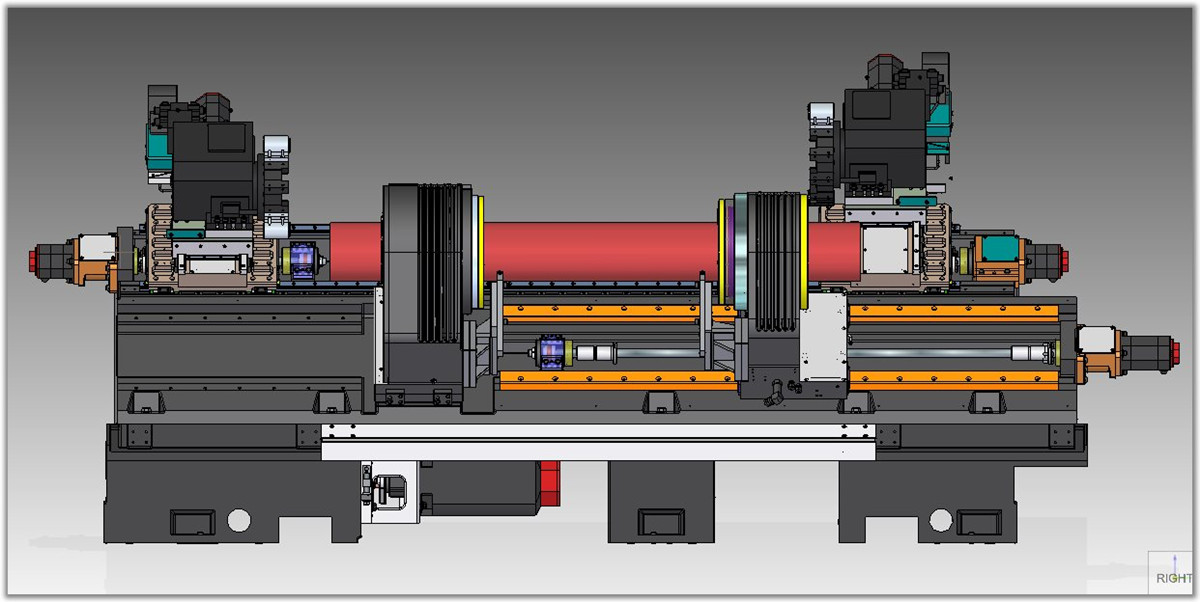

Ma SCK Series Awiri-mapeto a CNC Lathe Introduction

■ Pawiri-mapeto pamwamba zapaderazi CNC lathe ndi mtundu wa mkulu-mwachangu ndi mkulu-mwatsatanetsatane zapamwamba zipangizo kupanga. Ikhoza nthawi imodzi kumaliza bwalo lakunja, nkhope yomaliza ndi dzenje lamkati la malekezero awiri a workpiece mu clamping imodzi. Poyerekeza ndi chikhalidwe ndondomeko clamping mbali kawiri ndi kutembenuka, izo ali ndi ubwino mkulu kupanga dzuwa, coaxiality wabwino ndi mkulu mwatsatanetsatane mbali kukonzedwa.

Panopa, pali mitundu yoposa 10 ya zitsanzo, clamping awiri: φ5-φ250mm, processing kutalika: 140-3000mm; ngati imaganiziridwa mwapadera pazigawo za chipolopolo cha chubu, kukula kwa clamping kumatha kufika φ400 mm.

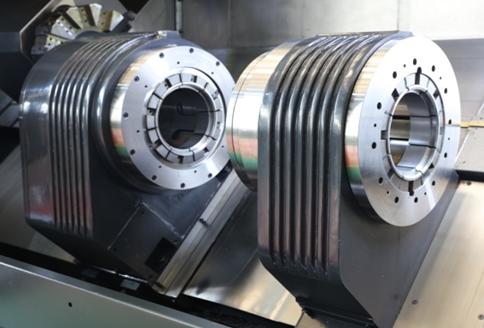

■Makina onse ali ndi masanjidwe a bedi 450, omwe ali ndi kukhazikika kwabwino komanso kuchotsa tchipisi kosavuta. Bokosi la spindle lomwe lili ndi drive yapakatikati ndi ntchito yokhotakhota imakonzedwa pakati pa bedi, ndipo zida ziwiri zopumira zimakonzedwa mbali zonse za bokosi la spindle.

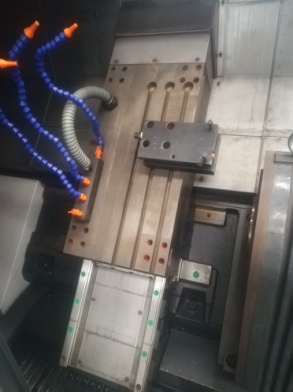

■ Pogwiritsa ntchito njira yoyendetsera njira ziwiri, zida ziwirizi zimatha kulumikizidwa ndi spindle nthawi imodzi kapena padera kuti amalize kukonza nthawi imodzi kapena kukonzanso motsatira mbali zonse za gawolo.

■ Gulu lililonse la servo feed axis limatenga wononga mpira wabata kwambiri, ndipo zolumikizira zotanuka zimalumikizidwa mwachindunji, ndi phokoso lochepa, kulondola kwa malo apamwamba komanso kubwereza kobwerezabwereza.

■ Malinga ndi kutalika kwa ma workpieces osiyanasiyana, 1-2 mitu yapakatikati pagalimoto imatha kukhala ndi zida. Pakati pawo, bokosi lalikulu lakumanzere la spindle limakhazikika, ndipo bokosi lakumanja la spindle limayendetsedwa ndi servo motor kusuntha wononga mpira ku Z mbali. Itha kungogwiritsa ntchito mutu waukulu kuti mutseke kuti amalize kukonza magawo amfupi; ingagwiritsenso ntchito mitu iwiri kuti igwirizane kuti imalize kukonza zigawo zazitali.

■ Bokosi la spindle limagwirizanitsa zigawo zisanu za spindle system, clamps, clamping cylinder, mafuta ogawa mafuta ndi makina oyendetsa galimoto, ndi mawonekedwe osakanikirana ndi ntchito yodalirika. Zida zokhomerera zonse zimayendetsedwa ndi hydraulically, ndipo clamping force imatha kukwaniritsa zosowa za torque yayikulu kwambiri.

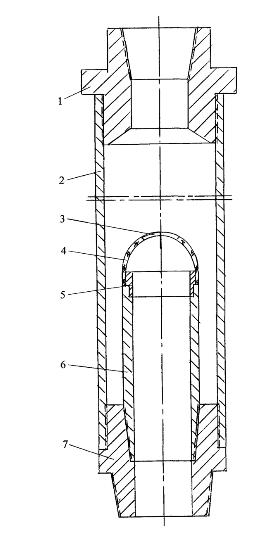

■ Zokonza zimayikidwa mu bokosi la spindle. Kapangidwe kazomwe zimapangidwira kumaphatikizapo mtundu wa collet wokhala ndi chotchingira chapakati ndi malekezero awiri, ndi chotchinga chapakati ndi nsagwada ziwiri zapakatikati.

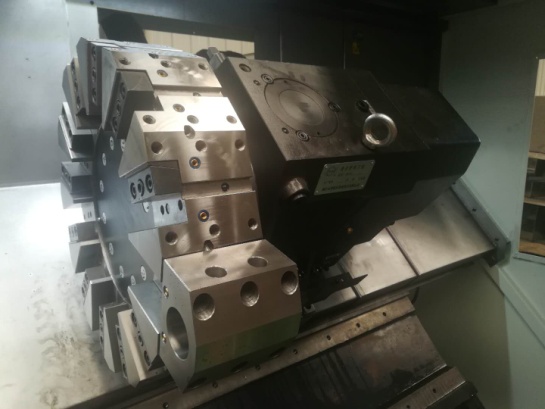

Poganizira mawonekedwe osavuta a ma cylindrical omwe amakhala ndi mipanda yopyapyala, ma collet clamps amagwiritsidwa ntchito. Ma clamps amayendetsedwa ndi pisitoni ya silinda kuti iwapangitse kupunduka kuti azindikire kuti chuck ikumasula kapena kugunda. Kupindika kwa chuck zotanuka ndi 2-3mm (m'mimba mwake). The chuck clamping gawo la gawo lonse circumferential malangizo, clamping mphamvu ndi yunifolomu, ndi mapindikidwe gawo ndi pang'ono. Pamene kulondola kwapang'onopang'ono kwa gawo la clamping kuli bwino, padzakhala kulondola kwapamwamba kwambiri. Panthawi imodzimodziyo, ndikofunikira kuchepetsa kusinthika kwa magawo kuti zigawozo zikhale ndi overhang yoyenera.

■ Pamene mbali ndi lalikulu m'mimba mwake specifications, ndi kusintha claw akhoza kuikidwa mu dongosolo chuck. Chikhadabo chowongolera ndi chikhadabo chofewa, chomwe chimakhazikika pakatikati pakatikati mwa clamp. Musanagwiritse ntchito, imakhala ndi kulondola kwakukulu kwa clamping ndikusintha mwachangu komanso kosavuta.

■Makinawa amatengera kapangidwe kake, ndipo amatha kukhala ndi mawonekedwe osiyanasiyana, masinthidwe ndi kuphatikiza kwa magwiridwe antchito malinga ndi zomwe wogwiritsa ntchito akufuna. Pali zosankha zambiri za positi yachida, monga mtundu wa zida za mizere, mtundu wa turret ndi turret yamphamvu. Zida ziwirizi zimatha kulumikizidwa ku spindle nthawi imodzi kapena padera kuti amalize kukonzanso nthawi imodzi kapena motsatizana mbali zonse za gawolo.

Kuphatikizika kwa chida: chogwirizira chida kawiri; chida cha mizere iwiri; chogwiritsira ntchito mphamvu; chida cha mzere wakumanzere + chogwirizira kumanja; chogwirizira kumanzere + chida cha mzere wakumanja.

■ Chida cha makina chimakhala chotsekedwa ndi kutetezedwa, chokhala ndi zodzoladzola zokha komanso zipangizo zochotseratu chip, zokhala ndi chitetezo chabwino, maonekedwe okongola, ntchito yosavuta komanso kukonza bwino.

■ Chida cha makinawo chikhoza kukhala ndi chimango chothandizira, chida chothandizira kutsitsa ndi kutsitsa, ndi chipangizo chotsitsa ndikutsitsa. Onani makanema ndi zithunzi zamakina.