Pawiri spindle CNC lathe 208 mndandanda

Kukonzekera Kwazinthu

Mawu Oyamba

TuretiDchizindikiroPkachitidwe

Mapangidwe ophatikizika abwino a Y-axis ndi olimba kwambiri, olemetsa, ndipo amagwira ntchito bwino kuposa Y-axis yomasulira.

·Kukonza mikombero yandege yosalala komanso yosalala

·Kusavuta kukonza malo opindika komanso mikombero

Poyerekeza ndi "kutanthauzira Y", "Y yabwino" ili ndi ubwino woonekera pa mphero ya ndege. Kusuntha kwa "Y" Y-axis kumayenderana ndi X-axis ndipo ndikuyenda kwa axis imodzi. "Kutanthauzira Y" Y-axis kayendedwe ndikulowetsa mzere wowongoka kudzera mumayendedwe amodzi a X-axis ndi Y-axis. Poyerekeza ndi "Y yowoneka bwino" ya kusalala kwa ndege yogaya, "yowoneka bwino Y" axis processing ndi yowala komanso yosalala.

ChindunjiDmtsinjeSwofananaEzamaphunziroSpindle

Kukhazikika kwakukulu, torque yayikulu, kuchita bwino kwambiri, kumaliza bwino, kulondolera kolondola kwambiri.

Zigawo zonse zazikulu zamakina zimapangidwa ndi chitsulo choponyedwa HT300 chokhala ndi mphamvu yoyamwa mwamphamvu kwambiri.

Mawonekedwe a zida zamakina okhala ndi ma spindle amagetsi oyendetsa molunjika

●Maginito ring encoder (sine ndi cosine) malo olondola: 20 arc seconds,

Kulondola kwa C-axis indexing: 40 arc masekondi

● Kuthamanga koyambira kuyimitsa, kupulumutsa nthawi ya chida cha makina ndikuwongolera bwino mphamvu zopanga

● Katundu wocheperako, kupulumutsa mphamvu ndi kupulumutsa mphamvu, chitetezo chabwino cha zida zamakina ndi moyo wautali wautumiki

● Chotsani bwino kugwedezeka kwa spindle, kusinthasintha kwabwino, kumaliza kwabwino, ndikuwongolera kutha kwa ntchito

(Ubwino wotembenuza m'malo mokupera, mawonekedwe okhotakhota, roughness Ra 0.2μm)

· Spindle motor ili ndi makina ozizirira kuti athetse kusuntha kwa kutentha ndikuwonetsetsa kuti spindle ikugwirabe ntchito kutentha kosasintha.

(Kulondola kwa mphuno yothamanga kuli mkati mwa 0.002mm, kuwonetsetsa kukhazikika kokhazikika)

· Kumbuyo-wokwera molunjika pagalimoto synchronous spindle, yosavuta kukhazikitsa ndi kukonza

A2-5: 7016AC-kutsogolo awiri kumbuyo awiri

· A2-6: kutsogolo NN3020+100BAR10S, kumbuyo NN3018

A2-8: kutsogolo NN3024+BT022B*2, kumbuyo NN3022

Zolemera-DuwuCmongaIronBaseAnd Cotsutsa

Ma castings onse amakongoletsedwa pogwiritsa ntchito finite element analysis (FEA) kuti achepetse kupotoza ndi kukweza mphamvu ya mayamwidwe. Mapangidwe a magulu akuluakulu a lathes amalimbikitsidwa ndi nthiti kuti apititse patsogolo kusasunthika ndi kukhazikika kwa kutentha. Mitu yophatikizika komanso yofananira ndi tailstock imapangitsanso kukhazikika ndikuwonetsetsa kulondola komanso kubwerezabwereza.

Mfundo Zaukadaulo

| Kanthu | Dzina | Chigawo | 208MS | Mtengo wa 208MSY |

| Maulendo | Max. kuzungulira kwa bedi | mm | Φ680 | Φ700 |

| Max. makina awiri | mm | Φ370 | Φ300 | |

| Max. kuzungulira kwa chogwirizira | mm | Φ300 | Φ300 | |

| Max. processing kutalika | mm | 420 | 400 | |

| Mtunda pakati pa malo awiri | mm | - | - | |

| Spindle Silinda Chuck | Mphuno ya spindle | ASA | A2-6 | A2-6 |

| Silinda ya Hydraulic / chuck | Inchi | 8'' | 8'' | |

| Spindle kudzera m'mimba mwake | mm | Φ79/66 | Φ79/66 | |

| Max. ndodo kudzera m'mimba mwake | mm | Φ65/52 | Φ65/52 | |

| Spindle Max. liwiro | rpm pa | 4300 | 4300 | |

| Spindle motor mphamvu | kw | 18/22 | 18/22 | |

| Spindle motor torque | Nm | 91-227 | 91-227 | |

| Sub-Spindle Silinda Chuck | Sub-Mphuno ya spindle | ASA | A2-5 | A2-5 |

| Sub-Silinda ya Hydraulic / chuck | Inchi | 6” | 6” | |

| Sub-Spindle kudzera m'mimba mwake | mm | Φ56 | Φ56 | |

| Sub-Max. ndodo kudzera m'mimba mwake | mm | Φ46 | Φ46 | |

| Sub-Spindle Max. liwiro | rpm pa | 5500 | 5500 | |

| Sub-Spindle motor mphamvu | kw | 17.5 | 17.5 | |

| X/ZN/SAxisFeedPma aramu | X mphamvu yamagalimoto | kw | 2.5 | 2.5 |

| Y mphamvu yamoto | kw | - | 1.2 | |

| Z mphamvu yamagalimoto | kw | 2.5 | 2.5 | |

| Smphamvu zamagalimoto | Kw | 1.2 | 1.2 | |

| Xulendo ozungulira | mm | 236 | 204 | |

| Yulendo ozungulira | mm | - | 100±50 | |

| Zulendo ozungulira | mm | 510 | 492 | |

| Mafotokozedwe a X/Z axis njanji | spec | 35 roller | 35 roller | |

| Mafotokozedwe a Y axis njanji | spec | 25 wodzigudubuza | 25 wodzigudubuza | |

| S olamulira kuyenda | mm | 600 | 600 | |

| Xaxis kusuntha mwachangu | Mm/mphindi | 20 | 20 | |

| Zaxis kusuntha mwachangu | Mm/mphindi | 20 | 20 | |

| Yaxis kusuntha mwachangu | Mm/mphindi | - | 8 | |

| Saxis kusuntha mwachangu | Mm/mphindi | 24 | 24 | |

| Servo mphamvu TuretiPma aramu | Mtundu wa turret wamphamvu | / | Mtengo wa BMT55 | Mtengo wa BMT55 |

| Malo opangira zida | / | 12T | 12T | |

| M mphamvu yamoto | kw | 5.5 | 5.5 | |

| M axis motor torque | Nm | 35 | 35 | |

| Mutu wamphamvu Max. liwiro | rpm pa | 6000 | 6000 | |

| Mafotokozedwe a zida zogwirira ntchito zakunja | mm | 25*25 | 25*25 | |

| Mafotokozedwe a chida chamkati chamkati | mm | Φ40 | Φ40 | |

| Nthawi yosinthira chida choyandikana | mphindi | 0.15 | 0.15 | |

| Kuyika kulondola | / | ±2” | ±2” | |

| Bwerezani kulondola kwa malo | / | ±1” | ±1” | |

| TailstockPma aramu | Programmable hydraulic tailstock | / | - | - |

| Mtengo wa Tailstock Max. kuyenda | mm | - |

| |

| Diameter ya manja | mm | - |

| |

| Kuyenda kwa manja | mm | - |

| |

| Chovala cha manja | / | - |

| |

| Makulidwe | Miyeso yonse | m | 2800*2100 * 1800 | 2700*2400*2000 |

| Kulemera kwa makina pafupifupi. | kg | 5900 | 5300 | |

| Zina | Kudula voliyumu ya tanki yamadzi | L | 150 | 150 |

| Mphamvu yopopa madzi ozizira | kw | 0.75 | 0.75 | |

| Voliyumu ya bokosi la hydraulic unit | L | 40 | 40 | |

| Mphamvu yamagetsi yamagetsi yamafuta a Hydraulic | kw | 1.5 | 1.5 | |

| Kuchuluka kwa tanki yamafuta | L | 2 | 2 | |

| Makina opangira mafuta pampu mphamvu yamagalimoto | kw | 50 | 50 |

Chiyambi Chokonzekera

ZosavutirakoTo Use And MorePzamphamvu

●Mapangidwe apamwamba kwambiri

● Okonzeka ndi i HMI

●Zokhala ndi luso lamakono la FANUC la CNC ndi servo

●Zokhazikika ndi zokonda zanu

●Kuchuluka kwa kukumbukira

KumasukaOf Use

Pewani kutsika kwadzidzidzi kwa makina mwa kukonza zodzitetezera

● Ntchito zolosera zolakwika zambiri

Pezani mosavuta malo olakwika ndikufupikitsa nthawi yochira

●Kuzindikira/kusamalira

Mkulu processing ntchito

KufupikitsidwaCycleTine

● Ukadaulo wowongolera bwino kwambiri

Kukwaniritsa apamwamba processing

Ukadaulo waukadaulo wapamtunda

● Kuzindikira/kusamalira ntchito

WapamwambaOperationRadadya

Nthawi zonse thandizirani ntchito zosiyanasiyana pamalo opangira

●FANUC

Zokonda makondaScreenIs EasierTo Use

●Mulingo wokhazikika wamunthu

Zoyambira m'munda wa IoT

●Kuthandizira ma netiweki osiyanasiyana pamasamba

THKBzonseSogwira ntchito

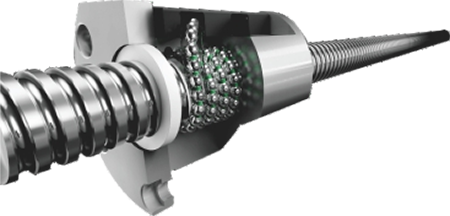

· C3 giredi, pogwiritsa ntchito wononga zolondola kwambiri za mpira, zokhala ndi nati wodzaza kale ndi zomangira zomangira zisanakhazikike kuti zithetseretu kubwelerana ndi kukwera kwa kutentha, kuwonetsa malo abwino kwambiri komanso kubwereza kubwereza.

· Servo motor direct drive kuti muchepetse zolakwika za backlash.

THKRollerLineGuwu

·P grade ultra-high rigidity SRG precision grade, linear kalozera zero chilolezo, arc kudula, bevel kudula, mawonekedwe pamwamba ndi ofanana. Oyenera ntchito yothamanga kwambiri, kuchepetsa kwambiri mphamvu yamahatchi yofunikira pazida zamakina.

·Kugudubuzika m'malo motsetsereka, kukangana pang'ono, kuyankha movutikira, malo olondola kwambiri. Iwo akhoza kunyamula katundu mu kusuntha malangizo pa nthawi yomweyo, ndi njanji kukhudzana pamwamba akadali mu Mipikisano mfundo kukhudzana pa katundu, ndi kudula rigidity si kuchepetsedwa.

·Zosavuta kuphatikiza, zosinthika mwamphamvu, komanso mawonekedwe osavuta opaka mafuta; kuchuluka kwa kuvala kumakhala kochepa kwambiri ndipo moyo wautumiki ndi wautali.

SKFBkhutu/OiliMachine

· Makina opangira mafuta opangira makina amakwaniritsa zosowa zamagwiritsidwe osiyanasiyana, oyenera pamikhalidwe yosiyanasiyana yogwirira ntchito, zinthu zodalirika, kugwiritsa ntchito kosinthika.

❖ Kukwaniritsa zofunikira zonyamula mafuta pa kutentha kwambiri, kugwedezeka kwamphamvu komanso malo owopsa.

Malo aliwonse opaka mafuta amagwiritsa ntchito voliyumu yofananira yogawa kuwongolera kuchuluka kwamafuta, ndipo makinawo amatha kuwongoleredwa ndi PLC kuti apereke mafuta molondola.