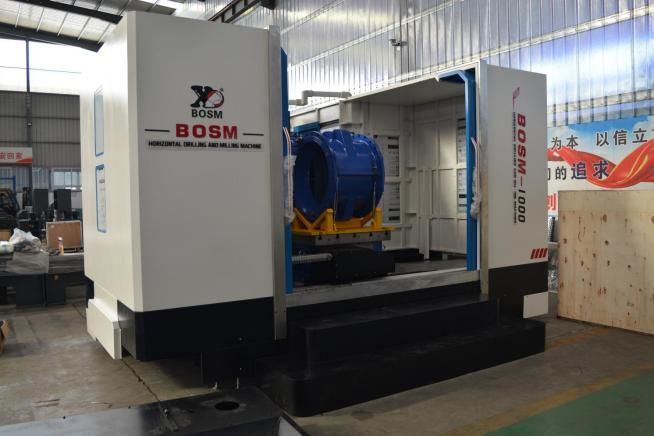

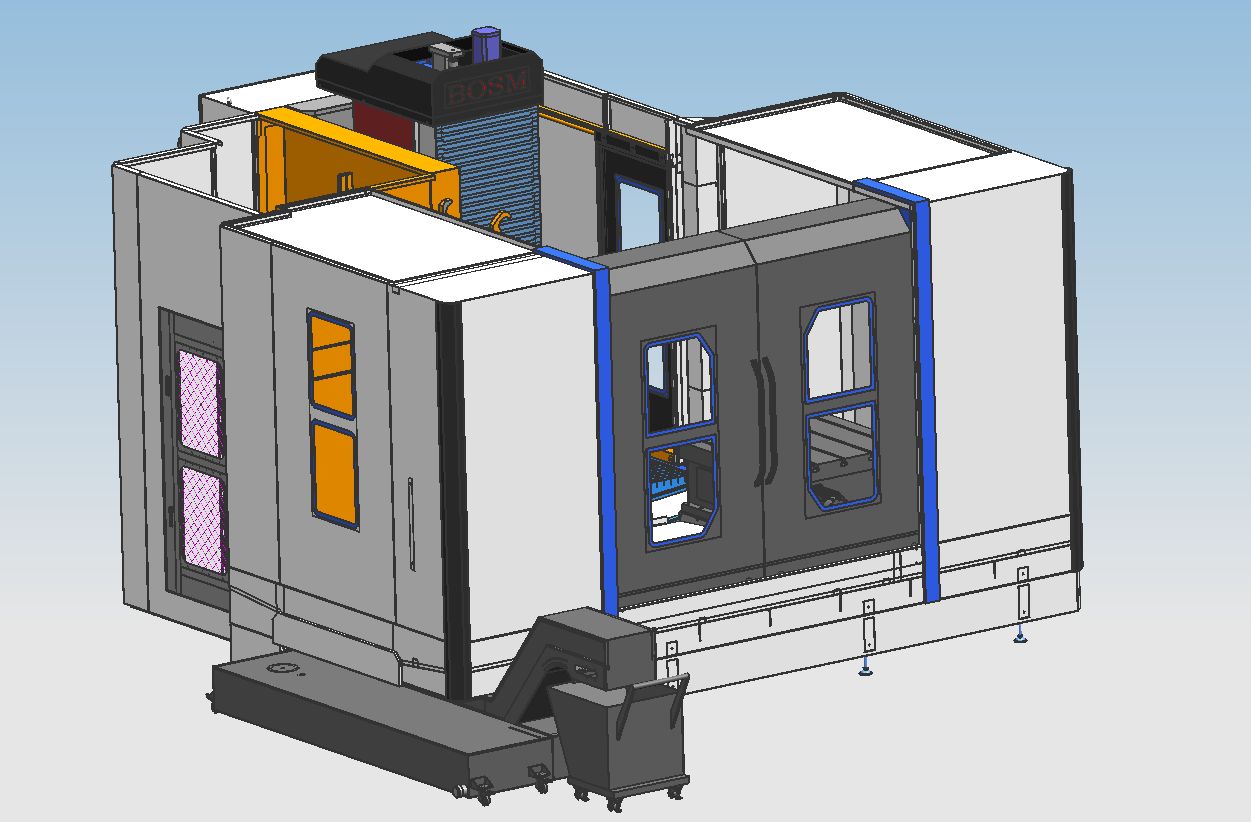

BOSM -4Z2000 High liwiro CNC pobowola ndi mphero makina

1. Kugwiritsa ntchito zida:

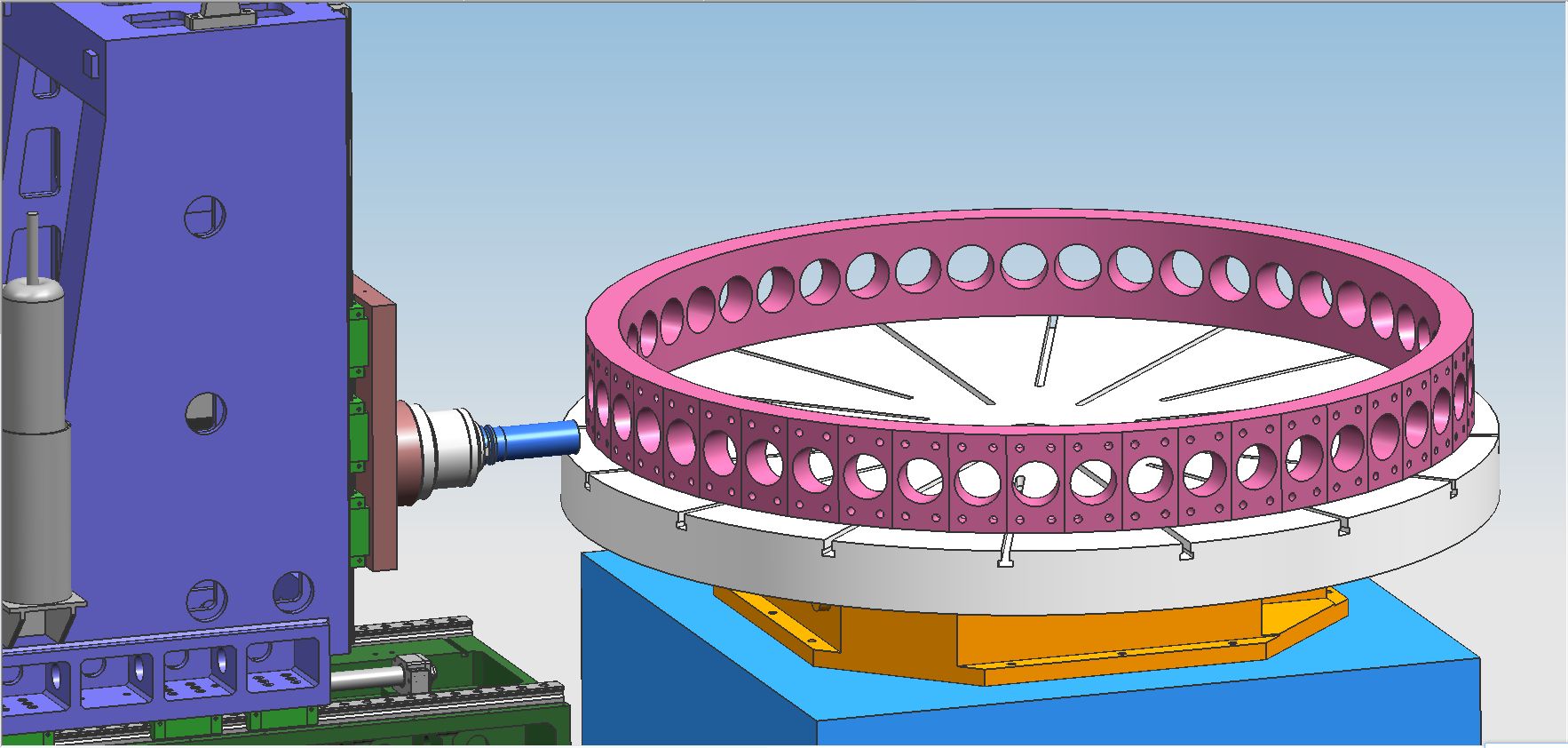

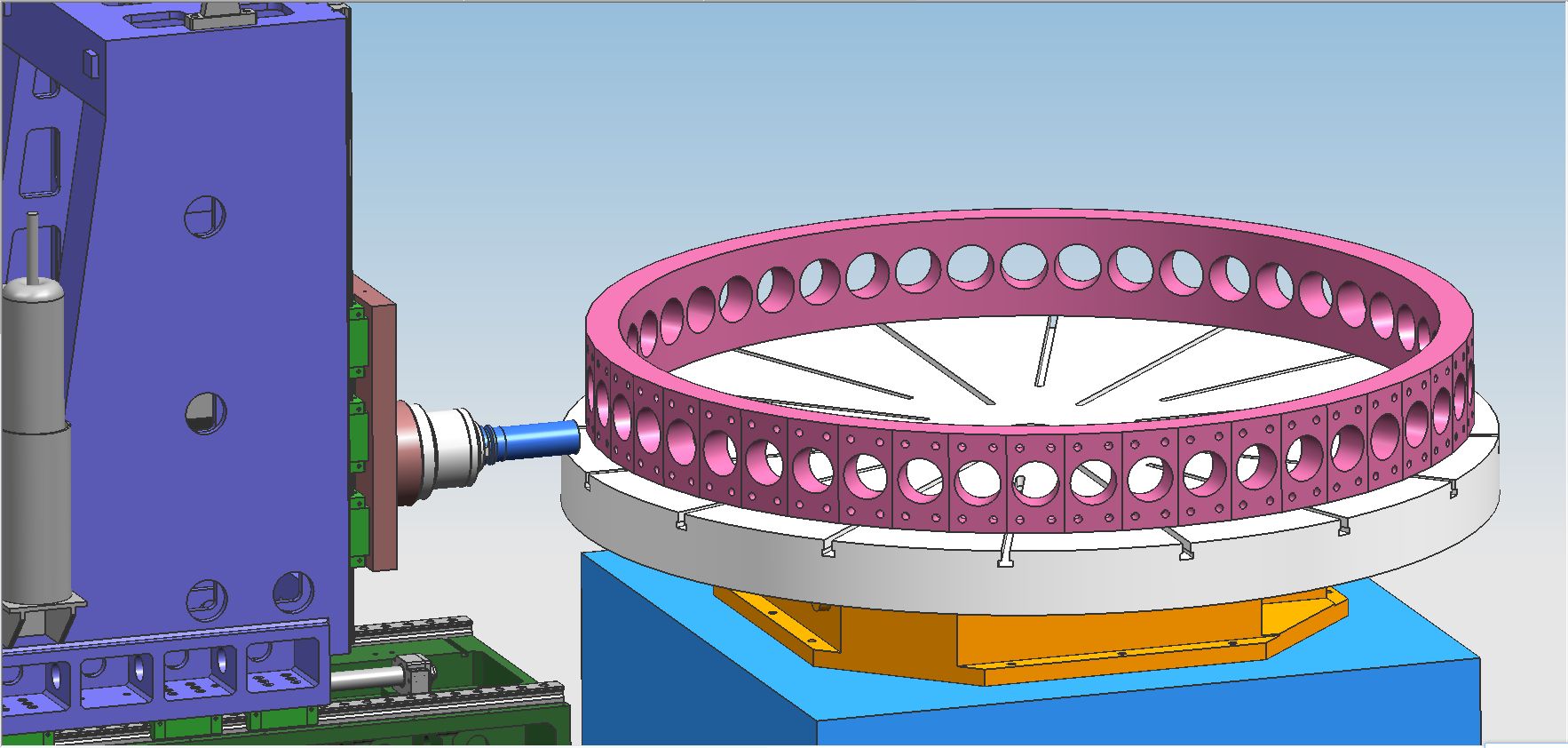

BOSM-1000 yopingasa CNC pobowola ndi makina mphero makamaka ntchito Mipikisano faceted imayenera kubowola, mphero, pogogoda ndi wotopetsa processing mavavu, midadada valavu, reducers, flanges, zimbale, mphete, zothandizira kupha ndi zina workpieces mkati ogwira osiyanasiyana makulidwe. . Kubowola, mphero, kugogoda ndi kutopa kumatha kuzindikirika pazigawo zakuthupi ndi zinthu zophatikizika. Njira yopangira makina imayendetsedwa ndi digito, ndipo ntchitoyo ndiyosavuta kwambiri. Itha kuzindikira zodzichitira, zolondola kwambiri, zamitundumitundu komanso kupanga zambiri.

2. Kapangidwe ka zida:

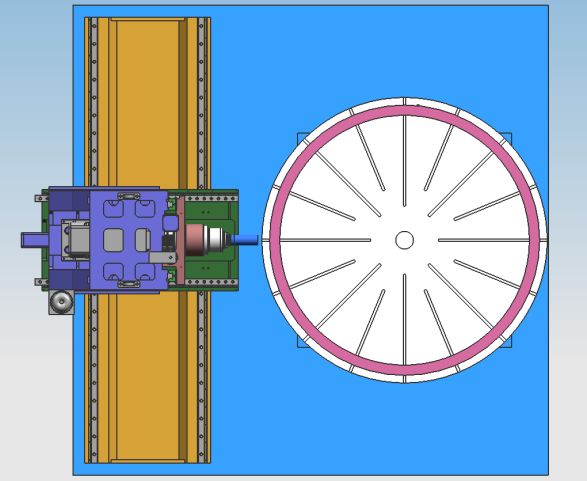

Chida ichi chimapangidwa makamaka ndi bedi, CNC indexing rotary table, mzati wosunthika, chishalo chosunthika, kubowola ndi mphero yamagetsi, chipangizo chodzitchinjiriza ndi chitetezo, chida chozungulira chozizirira, makina owongolera digito, ma hydraulic system, magetsi ndi zina zotero. Sitima yapamtunda yozungulira imathandizidwa ndikuwongoleredwa, ndipo zomangira zolondola zimayendetsedwa. Makinawa ali ndi malo olondola kwambiri komanso kubwereza kulondola kwa malo.

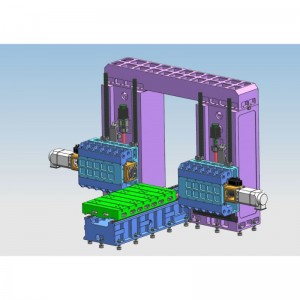

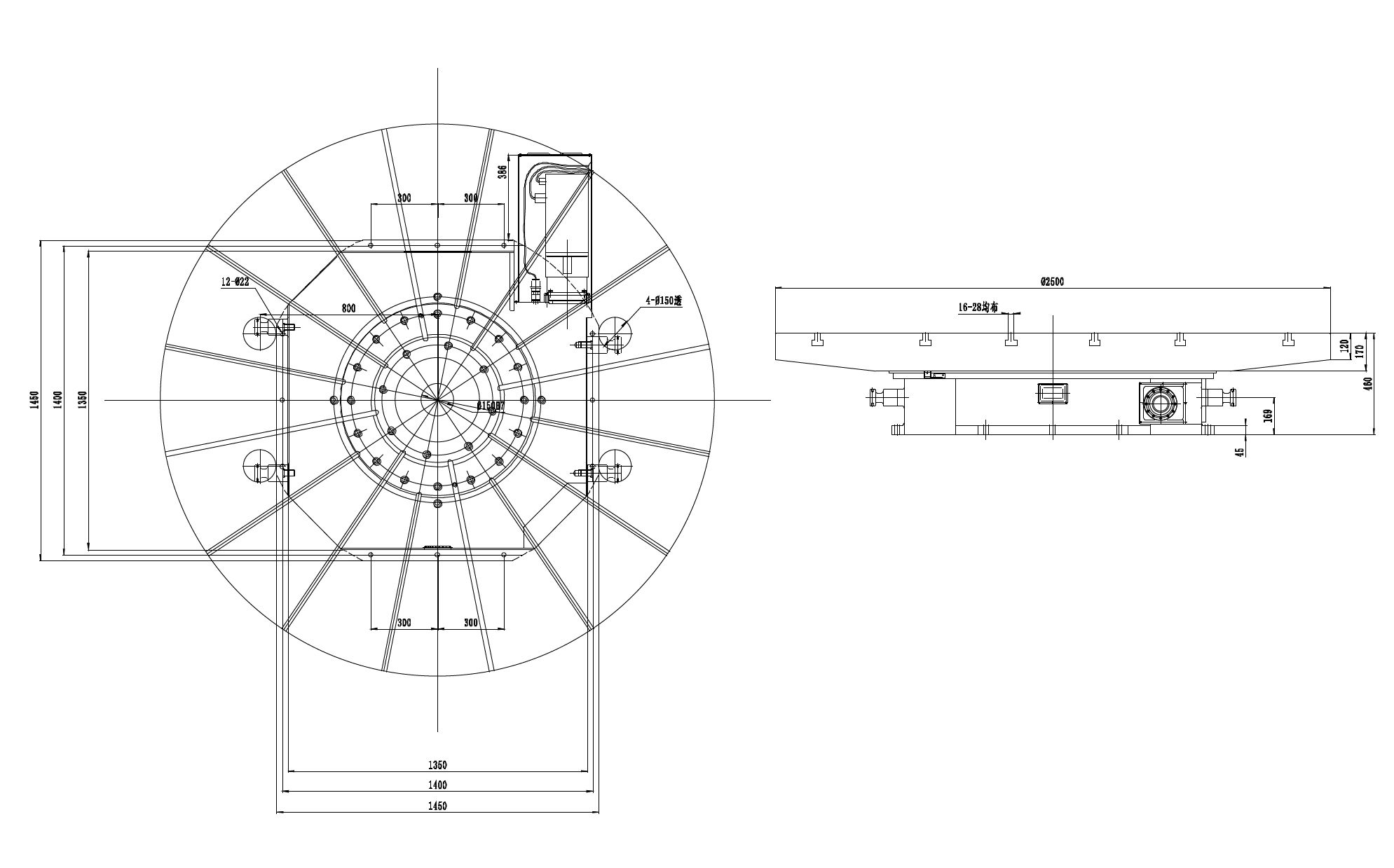

2.1. Bedi logwirira ntchito: Bedi ndi lopangidwa ndi HT250 zitsulo zotayidwa. Imamalizidwa pambuyo pa kutentha kwachiwiri kuchotsa kupsinjika kwamkati. Ili ndi mphamvu yabwino komanso yosasunthika komanso yopanda mapindikidwe. Cholozera cholozera cholondola cha manambala, servo drive 360 ° yolondolera mopanda tsankho ndi kutseka kwa mpweya/hydraulic, makina oyendetsa amagwiritsa ntchito AC servo mota kuti alembe okha shaft yozungulira gawo 360 °, ndipo kulondola kwa indexing ndi gawo limodzi mwa magawo chikwi chimodzi cha digiri. Cholozera cholozera chimayikidwa pamwamba pa bedi, ndipo mabawuti osinthika amagawidwa pansi pa bedi, omwe amatha kusintha mosavuta kuchuluka kwa bedi logwirira ntchito.

2.2. Mzere wosunthika: Chigawo chachitsulo chosunthika chimamalizidwa pambuyo pa kutenthetsa kwachiwiri kuchotsa kupsinjika kwamkati. Ili ndi mphamvu yabwino komanso yosasunthika komanso yopanda mapindikidwe. Seti ya slide yolondola kwambiri ndi injini ya servo imapangitsa kuti slide ikhale yolowera ku Y-axis. Seti ya slide yolondola kwambiri ya mpira ndi injini ya servo imapangitsa kuti slide ikhale yolowera ku X-axis. Ikani chobowola pa unit slide. Kusuntha kwa chipilala kumazindikirika ndi kuzungulira kwa nati ya mpira pa screw screw yoyendetsedwa ndi servo motor kudzera pakulumikizana.

2.3. Chishalo cham'manja: Chishalo cham'manja chimakhala ndi ma njanji awiri okwera kwambiri omwe amagudubuza njanji, seti ya njanji yolondola kwambiri ndi injini ya servo, yomwe imayendetsa mutu wobowola kuti usunthire mbali ya Z-axis, yomwe imatha. zindikirani Mphamvu mutu mwachangu, gwirani ntchito patsogolo, sinthani mwachangu, imani ndi zina. Ili ndi ntchito za automatic chip breaking, kuchotsa chip ndi kuyimitsa.

2.4. Kubowola mutu: Mphamvu pobowola mutu utenga Taiwan makina spindle, ndipo mwatsatanetsatane mwatsatanetsatane spindle utenga ang'ono kukhudzana kunyamula, amene amazindikira stepless liwiro kufala kudzera mkulu-mphamvu synchronous lamba kufala. Amayendetsedwa ndi ma servo motors ndi zomangira za mpira. Y-axis imatha kulumikizidwa, kutengera kuwongolera kotsekeka, ndipo imatha kuzindikira ntchito zomasulira zozungulira komanso zozungulira. Mapeto a spindle ndi BT50 taper hole.

2.5. Chida chodzitchinjiriza chodzitchinjiriza ndi chitetezo:

Makinawa ali ndi chipangizo chodziyimira pawokha, chomwe chimatha kudzipangira mafuta awiriawiri osuntha monga njanji zowongolera, zomangira zotsogola, ndi zoyala. Makina

Z-axis ndi Y-axis zili ndi zotchingira zoteteza fumbi, ndipo zotchingira zopanda madzi zimayikidwa mozungulira chogwirira ntchito.

2.6. Dongosolo lathunthu lowongolera manambala a digito:

2.6.1. Ndi chip breaking function, chip breaking time ndi chip breaking cycle zitha kukhazikitsidwa pamakina amunthu.

2.6.2. Okonzeka ndi chida chokweza ntchito, chida chokweza kutalika chikhoza kukhazikitsidwa pa mawonekedwe a makina a munthu. Kubowola kukafika pamtunda uwu, chobowolacho chimakwezedwa mwachangu pamwamba pa chogwirira ntchito, ndiye tchipisi timatayidwa, kenako chimatumizidwa kumalo obowola ndikusinthidwa kuti chigwire ntchito.

2.6.3. Bokosi lapakati loyang'anira ntchito ndi gawo logwiridwa pamanja limatenga makina owongolera manambala ndipo ali ndi mawonekedwe a USB ndi LCD lamadzimadzi a crystal display screen. Pofuna kuwongolera mapulogalamu, kusungirako, kuwonetsera ndi kulankhulana, mawonekedwe ogwiritsira ntchito ali ndi ntchito monga kukambirana ndi makina a munthu, kubwezera zolakwika, ndi alamu yokha.

2.6.4. Zidazi zimakhala ndi ntchito yowoneratu ndikuwunikanso malo a dzenje musanayambe kukonza, ndipo ntchitoyi ndi yabwino kwambiri.

* Pofuna kuonetsetsa kuti kukweza ndi kudyetsa mphete zazikulu, Makinawa alibe chitetezo chakunja, ndipo chitetezo chakunja ndichosankha.

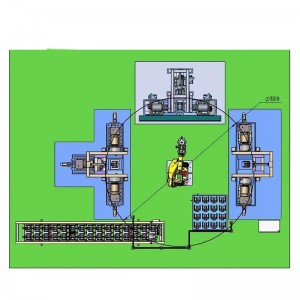

3. Makinamalo ogwiritsira ntchito:

Mphamvu: magawo atatu AC380V ± 10%, 50Hz ± 1 Kutentha kozungulira: 0 ° ~ 45 °

4.Zosintha zaukadaulo

| Chitsanzo | BOSM-1000 | |

| Zolemba malire processing workpiece kukula | Chovomerezeka chozungulira chozungulira cha workpiece (mm) | ≤Φ2000 |

|

Ntchito | Miyeso ya worktable (mm) lalikulu | □1000 |

| Miyeso ya worktable (mm) yozungulira | Φ1200 | |

| Katundu wopingasa (kg) | 5000 | |

|

Vertical Ram Drilling Unit | kuchuluka) | 1 |

| Spindle taper | Mtengo wa BT50 | |

| Kubowola m'mimba mwake (mm) | 2-120 | |

| Milling cutter disc diameter (mm) | 200 | |

| Kutalika kwapakati (mm) | M6-M36 | |

| Mtunda kuchokera kumaso opindika mpaka pakati pa tebulo (mm) | 1000-1600 | |

| Mtunda wochokera pakati pa spindle kupita kumtunda wa tebulo (mm) | 100-1100 | |

| Liwiro la spindle (r/min) | 30-3000 | |

| Spindle motor power (kw) | 30 | |

| Ntchito nsonga yozungulira (Axis) | Nambala yopambana kwambiri (mm) | 360 ° |

| Khazikitsani gawo locheperako | 0.001 ° | |

| A-axis servo motor mphamvu (kw) | 4.2 | |

| Mutu wamphamvu umayenda kumanzere ndi kumanja (X axis) | Kukwapula kwakukulu (mm) | 2000 |

| Kuthamanga kwa X-axis (m/mphindi) | 0~8 pa | |

| X-axis servo motor mphamvu (kw) | 2.4 | |

| Mutu wamphamvu umayenda mmwamba ndi pansi (Y axis) | Kukwapula kwakukulu (mm) | 1000 |

| Liwiro la Y-axis (m/min) | 0~8 pa | |

| Y-axis servo motor mphamvu (kw) | 2.4 Brake | |

| Kusuntha kwakutali kwa Column (Z axis) | Kukwapula kwakukulu (mm) | 600 |

| Kuthamanga kwa Z-axis (m/min) | 0~4 pa | |

| Z axis servo motor mphamvu (kw) | 2.4 | |

| Kuyika kulondola | 1000 mm | ± 0.05 |

| Kubwerezabwereza | 1000 mm | ± 0.025 |

| CNC indexing table index kulondola (mm) |

| 15” |

| Makulidwe a makina (kuphatikiza chitetezo) | Utali (X) × M’lifupi (Z) × Kutalika (Y) (mm) | 5300*6000*3400 |

| Kulemera kwakukulu (t) kuphatikiza chitetezo | (pafupifupi) 20 | |