BOSM -Horizontal Counter Drilling and Boring Machine

1. Kugwiritsa ntchito zida:

BOSM yopingasa pobowola ndi makina otopetsa ndi Makina apadera a kampani yanu kuti azikonza zipewa za tower crane. Makinawa ali ndi zida ziwiri zobowola zopingasa komanso mitu yamphamvu yotopetsa, yomwe imatha kuzindikira kubowola, mphero komanso kutopa kwa zida zogwirira ntchito mkati mwa sitiroko yabwino. Kudula ndi processing zina, zida udindo liwiro ndi kudya, kulondola processing ndi mkulu, ndi dzuwa processing ndi mkulu.

2. Makhalidwe a zida:

2. 1. Zigawo zikuluzikulu zaMakina

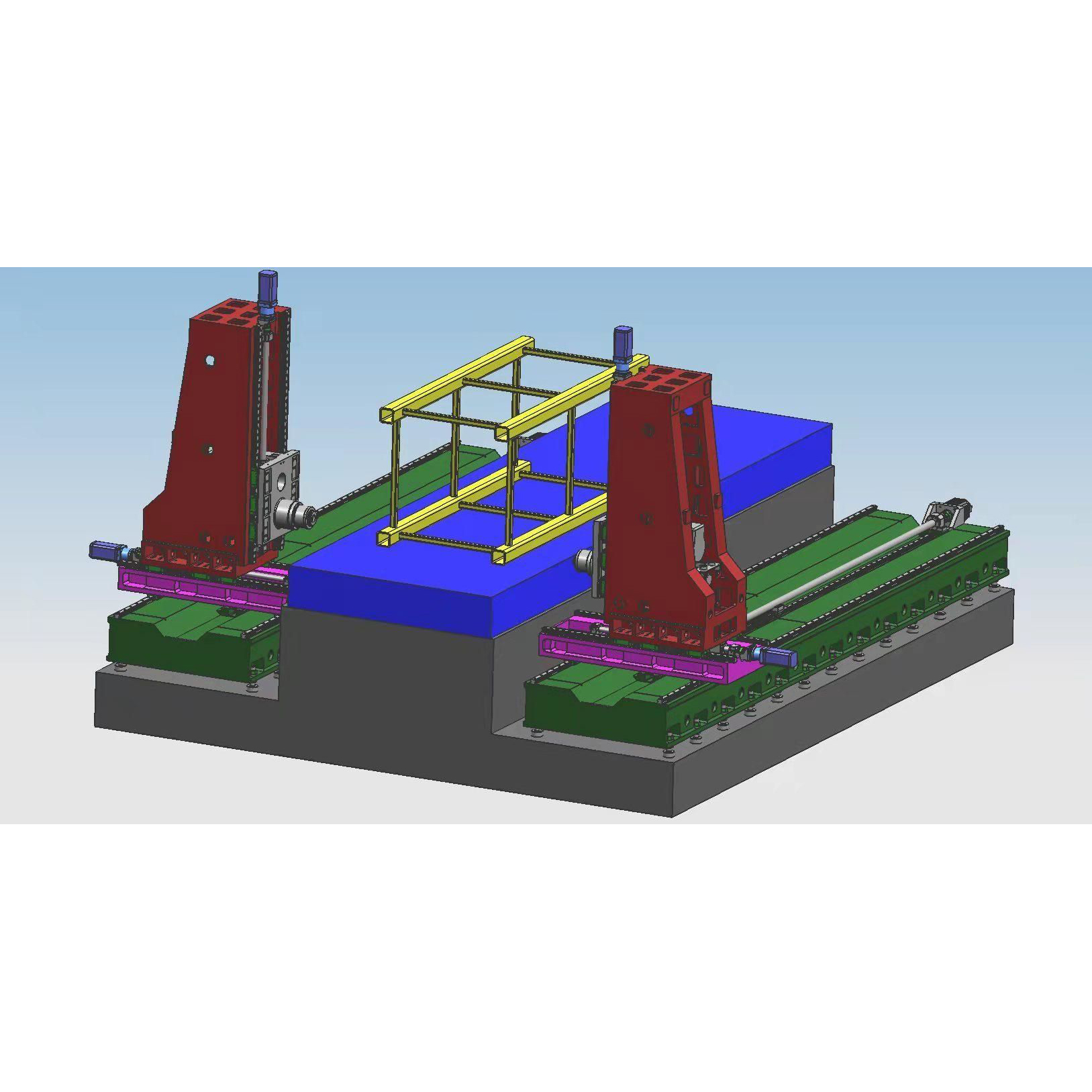

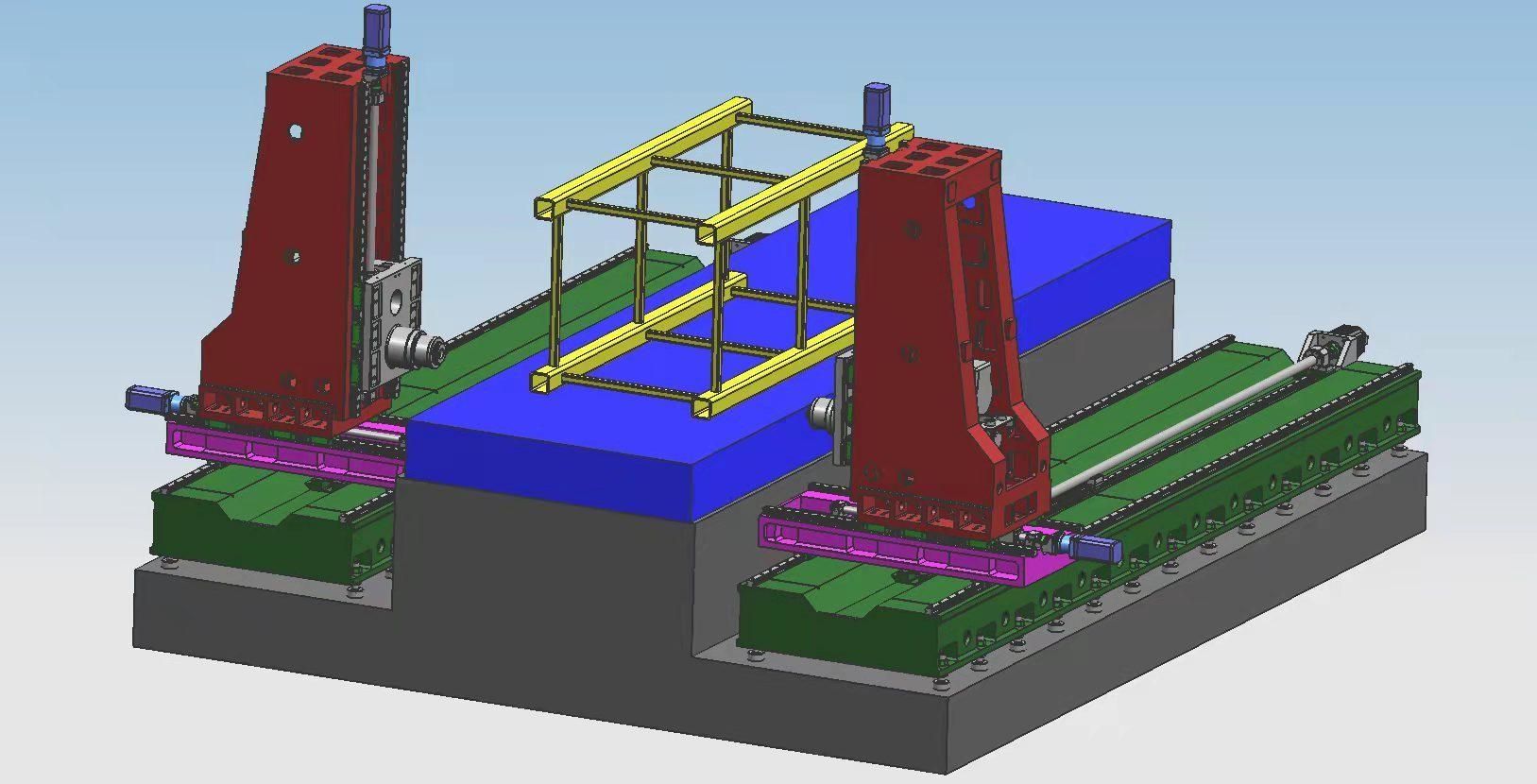

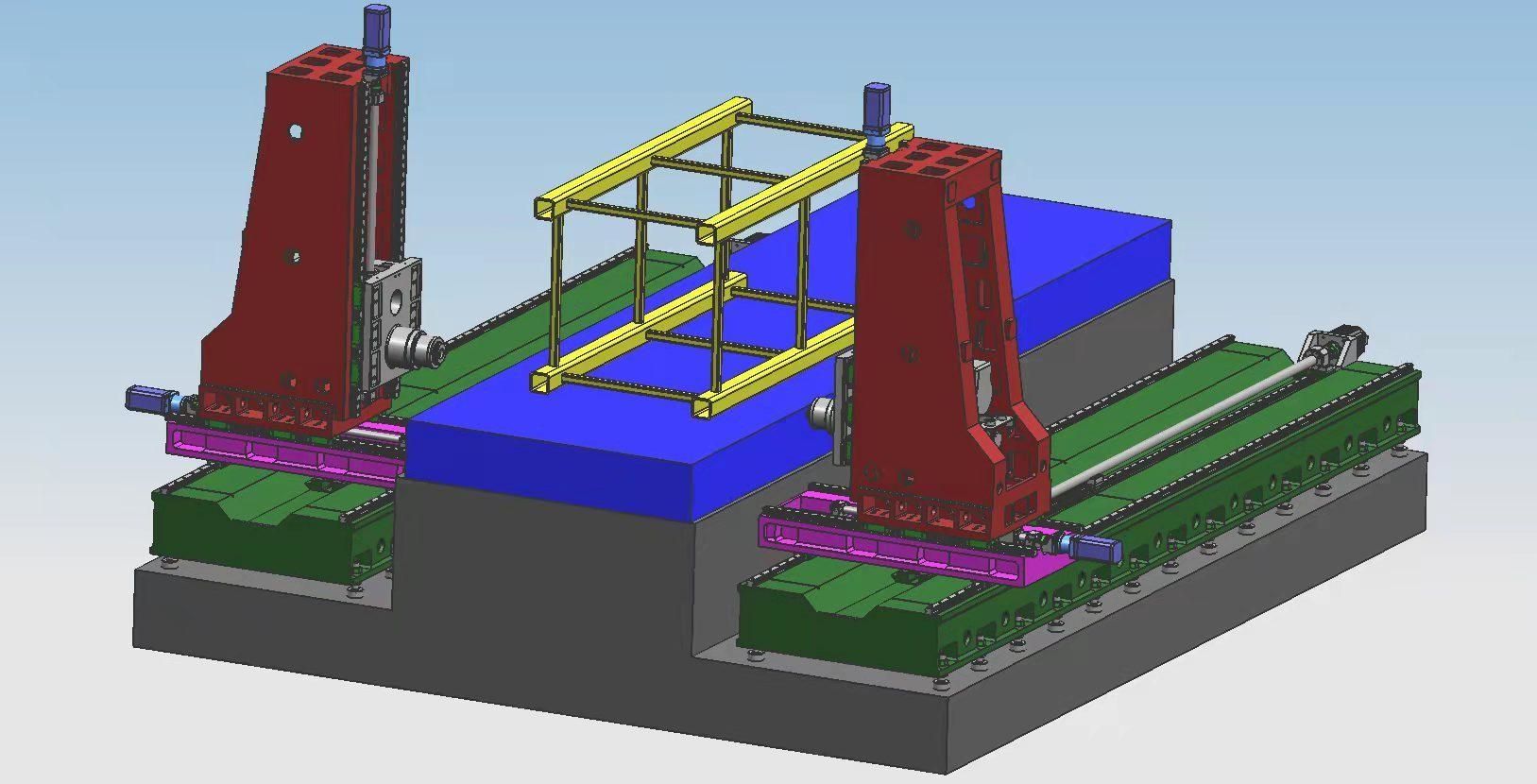

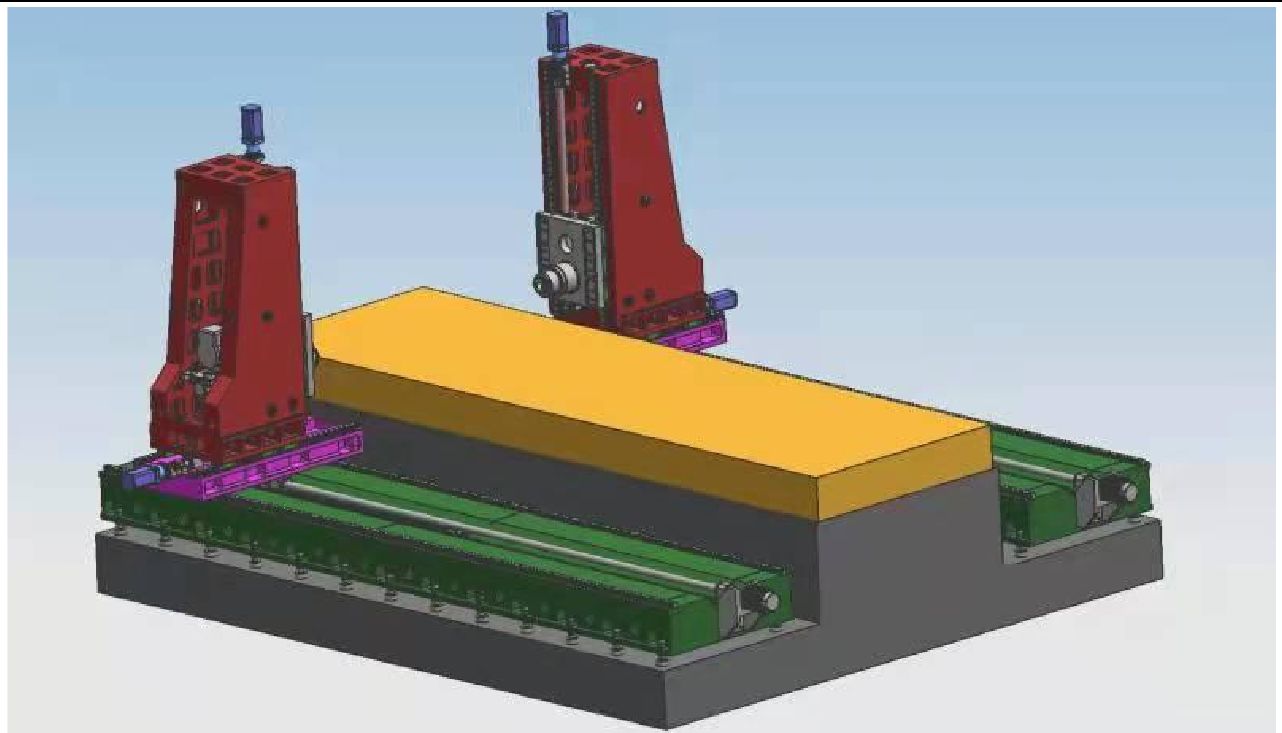

Zigawo zazikulu za Makina: bedi, zogwirira ntchito, zipilala kumanzere ndi kumanja, zishalo, nkhosa zamphongo, ndi zina zambiri, zigawo zazikulu zimapangidwa ndi utomoni wa mchenga, chitsulo chamtengo wapatali cha 250 choponyera, chomangidwira mu dzenje lotentha → kugwedera kukalamba → kutentha kuyatsa ng'anjo→kugwederakugwedera→Kukonza mwaukali→kugwederakugwedera→kuwotcha ng'anjo→kugwederakunjenjemera→kumaliza kuthetsa kwathunthu kupsinjika koyipa kwa magawo ndikusunga magwiridwe antchito kukhala okhazikika. Chogwirira ntchito cha zidacho chimakhazikitsidwa, ndipo mitu yamphamvu kumbali zonse ziwiri imatha kusuntha kutsogolo ndi kumbuyo kwa maziko; Makinawa ali ndi ntchito monga kubowola, kusangalatsa, kuwerengera, kugogoda, ndi zina zotero. Njira yozizira ya chida ndi kuzizira kwamkati kuphatikizapo kuzizira kwakunja. Makinawa ali ndi nkhwangwa 5 zodyetsa, 2 mitu yamphamvu yodulira, yomwe imatha kulumikizidwa ndi nkhwangwa 5 nthawi imodzi, kapena imatha kuchita imodzi. Mayendedwe a axial a Machine ndi mutu wa mphamvu akuwonetsedwa pachithunzi pansipa.

2. 2 Waukulu dongosolo la axial kufala chakudya gawo

2.2.1 X axis: Mutu wamagetsi umabwererana motsatira njanji yowongolera poyambira.

X1-axis drive: AC servo motor kuphatikiza chotsitsa chapamwamba kwambiri cha mapulaneti chimagwiritsidwa ntchito kuyendetsa mutu wamagetsi kudzera pa screw drive ya mpira kuti izindikire kusuntha kwa X-axis.

Kutumiza kwa X2-axis: AC servo motor kuphatikiza chochepetsera chapamwamba kwambiri cha mapulaneti chimagwiritsidwa ntchito kuyendetsa mutu wamagetsi kudzera pa transmission ya mpira wononga kuti izindikire kuyenda kwa X-axis.

Mawonekedwe a njanji yowongolera: Njanji ziwiri zotsogola zamphamvu zazitali zimayikidwa pamasinthidwe otalikirapo.

2.2 Y1 axis: Mutu wa mphamvu umabwerera mmwamba ndi pansi pamzake.

Y1-axis drive: Adopt AC servo motor kuti muyendetse pa mpira wononga kuti muzindikire kuyenda kwa mzere wa Y1-axis. Fomu yowongolera njanji: 4 zidutswa za 45 mtundu wa njanji zowongolera.

2.2.3 Y2 axis: Mutu wa mphamvu umabwerera mmwamba ndi pansi pazanja.

Kutumiza kwa Y2-axis: AC servo motor imagwiritsidwa ntchito poyendetsa mpira kuti izindikire kuyenda kwa mzere wa Y1-axis.

Fomu yowongolera njanji: 4 zidutswa za 45 mtundu wa njanji zowongolera.

2.2.4 Z1 axis: Mutu wa mphamvu umabwerera mmbuyo ndi mtsogolo pa chishalo.

Z1-axis transmission: AC servo motor ndi high-precision planetary reducer amagwiritsidwa ntchito kuyendetsa kayendedwe ka mpira kuti azindikire kuyenda kwa mzere wa Z1-axis.

2.2.5 Z2 axis: Mutu wa mphamvu umabwerera mmbuyo ndi mtsogolo pa chishalo.

Z2-axis transmission: AC servo motor ndi high-precision planetary reducer amagwiritsidwa ntchito kuyendetsa kayendedwe ka mpira kuti azindikire kuyenda kwa mzere wa Z2-axis.

2.3. Kuchotsa chip ndi kuziziritsa

Pali zonyamula tchipisi tating'onoting'ono zomwe zimayikidwa kumbali zonse ziwiri pansi pa benchi yogwirira ntchito, ndipo tchipisi tachitsulo titha kutulutsidwa mu chotengera cha chip kumapeto kuti tipeze chitukuko chotukuka. Pali mpope woziziritsa mu thanki yozizirira ya chotengera cha chip, chomwe chitha kugwiritsidwa ntchito poziziritsa mkati + kuziziritsa kwakunja kwa chidacho kuti zitsimikizire kugwira ntchito ndi moyo wautumiki wa chidacho, ndipo choziziriracho chikhoza kubwezeretsedwanso.

3. Dongosolo lathunthu lowongolera manambala a digito:

3.1. Ndi chip breaking function, chip breaking time ndi chip breaking cycle zitha kukhazikitsidwa pamakina amunthu.

3.2. Ndi ntchito yokweza zida, mtunda wokweza chida ukhoza kukhazikitsidwa pamawonekedwe a makina amunthu. Mtunda ukafika, chidacho chidzakwezedwa mwachangu, ndiyeno tchipisi titayidwa, ndiyeno mwachangu kupita kumalo obowola ndikusinthidwa kuti chigwire ntchito.

3.2. Bokosi lapakati loyang'anira ntchito ndi gawo logwirizira m'manja limatenga makina owongolera manambala ndipo ali ndi mawonekedwe a USB ndi chiwonetsero cha LCD chamadzimadzi. Pofuna kuwongolera mapulogalamu, kusungirako, kuwonetsera ndi kulankhulana, mawonekedwe ogwiritsira ntchito ali ndi ntchito monga kukambirana ndi makina a munthu, kubwezera zolakwika, ndi alamu yokha.

3.2 .. Zidazi zimakhala ndi ntchito yowonetseratu ndikuwunikanso malo a dzenje musanayambe kukonza, ndipo ntchitoyi ndi yabwino kwambiri.

4. Makina opaka mafuta

Makina owongolera njanji olondola kwambiri, mawotchi olondola a mpira ndi zina zoyenda zolondola kwambiri zili ndi makina odzipaka okha. Pampu yodzitchinjiriza yokha imatulutsa mafuta othamanga, ndipo chipinda chamafuta opangira mafuta ochulukirapo chimalowa mumafuta. Chipinda chamafuta chikadzadza ndi mafuta ndipo kupanikizika kwa dongosolo kumakwera mpaka 1.4 ~ 1.75Mpa, chosinthira chopondera pamakina chimatsekedwa, pampu imasiya, ndipo valavu yotsitsa imatsitsidwa nthawi yomweyo. Kuthamanga kwamafuta mumsewu kutsika pansi pa 0.2Mpa, mafuta ochulukirapo amayamba kudzaza malo opaka mafuta ndikumaliza kudzaza mafuta amodzi. Chifukwa cha kuchuluka kwamafuta omwe amaperekedwa ndi oiler wochulukira komanso kuthekera kozindikira kupanikizika kwadongosolo, mafutawo amakhala odalirika ndikuwonetsetsa kuti pagulu lililonse la kinematic pali filimu yamafuta, yomwe imachepetsa kukangana ndi kuvala ndikuletsa kuwonongeka. kumapangidwe amkati chifukwa cha kutentha kwambiri. , kuonetsetsa kulondola ndi moyo wa Machine.

5. Makinamalo ogwiritsira ntchito:

Mphamvu: magawo atatu AC380V ± 10%, 50Hz ± 1 Kutentha kozungulira: -10 ° ~ 45 °

6. Zoyenera kulandira:

JB/T10051-1999 "General Technical Specifications for Hydraulic System of Metal Cutting Machines"

7. Zosintha zaukadaulo:

| Chitsanzo | 2050-5Z | |

| Zolemba malire processing workpiece kukula | Utali × m'lifupi × kutalika (mm) | 5000×2000×1500 |

| saizi ya desiki yogwira ntchito | Utali X M'lifupi (mm) | 5000*2000 |

| Power head base direction kuyenda | Yenda kumbuyo ndi mtsogolo (mm) | 5000 |

| Mphamvu mutu mmwamba ndi pansi | Kugunda mmwamba ndi pansi kwa nkhosa yamphongo (mm) | 1500 |

|

Yopingasa nkhosa yamphongo pobowola mutu mutu Mphamvu mutu 1 2 | Kuchuluka (2 pcs) | 2 |

| Spindle taper | Mtengo wa BT50 | |

| Kubowola m'mimba mwake (mm) | Φ2-Φ60 | |

| Kutalika kwapakati (mm) | M3-M30 | |

| Liwiro la spindle (r/min) | 30-3000 | |

| Servo spindle motor power (kw) | 22*2 | |

| Ulendo wakumanzere ndi kumanja (mm) | 600 | |

| Bidirectional Positioning Kulondola | 300mm * 300mm | ± 0.025 |

| Bi-directional kubwereza malo olondola | 300mm * 300mm | ± 0.02 |